This year is special for Chemistry and Life. Fifty years ago, in April 1965, the first issue of our magazine came out. It appeared on the wave of chemicalization, when a decision was made in the USSR to build the Big Chemistry. The main ideologist and organizer of this construction was Leonid Arkadyevich Kostandov, who would have turned a hundred years old this year. This is such a double anniversary, and each one is very dear to us.

But today our conversation is about Leonid Arkadyevich, about a great statesman. For twenty years of work in power (1965–1980 - Minister chemical industry USSR, 1980-1984 - Deputy Chairman of the Council of Ministers of the USSR), he created a powerful world-class chemical industry. On his account - hundreds (!) New and reconstructed chemical industries built in different republics. Through his efforts for twenty years specific gravity products of the chemical industry in national economy doubled. He, like a powerful locomotive, dragged the entire economy of the country. How many deeds and accomplishments in just 20 years!

If the pace set by L. A. Kostandov had been preserved after 1984, when he was gone, then now our chemical industry would be as powerful as in the USA, and would pull the rest of the industries along with it. Kostandov created an industrial reserve for decades to come, which had to be developed. It was this backlog that at one time could become a launching pad for an economic breakthrough. new Russia. But it turned out the opposite. For the last 25 years, our government has not only built but destroyed the chemical industry. Only now, when much has been destroyed, continuity has been lost, personnel have been lost, time has been lost, a technological lag has arisen, only now has the understanding returned that we need our own industry. And for this we need such attractive, talented and responsible leaders as Kostandov.

Alas, in the current government there are no such statesmen who could be brought closer to Kostandov at least a few steps - neither in competence, nor in efficiency, nor in the level of state thinking, nor in internal energy, nor in strategic vision, and indeed a lot of other things. Oh, if Leonid Arkadyevich were with us now!

Kostandov cannot be returned, but you can try to learn from his stunning practice government controlled and service to the Fatherland. The lessons are extremely relevant for today's Russia.

Competence

What do we expect from the government? The main thing is justice, as well as honesty, efficiency, focus on results in the interests of the country and the people, and of course competence.

I recently got into a conversation with a young man. I ask: what is your education? Says the manager. Understood, manager. And in what industry? What specialization? What is another specialization? I am a manager by education and can manage in any area. Okay, I say. And as a manager, can you evaluate the prospects for the production of an ethylene-maleic anhydride copolymer for electrical engineering, chlorinated polyethylene for rubber engineering, compressed natural gas as a substitute for gasoline, modification of acetate fibers ... Wait, what are you talking about? I didn't understand a single word! I'm the manager!

Meanwhile, all of the above are just a few issues that were considered during one day by the Minister of the Chemical Industry of the USSR L.A. Kostandov, manager of the highest standard, engineer by education.

Where did these strange and dangerous illusions come from that a non-specialist can manage this or that branch of the economy? That people who do not understand the essence of scientific work and teaching can lead science and education, officials who do not distinguish a valve from a fitting and do not understand the deep connections between industries - industry, people, do not knowing the essence chemical transformations and technologies, - the chemical industry... In the last 25 years, the economy in our country has been turned upside down. For some reason, financiers and lawyers, specialists in purely service professions, became the main ones in it.

The basis of the economy has always been, is and will be production, and the business of lawyers and financiers is to serve this main economic process. A lawyer, a financier and just a manager cannot understand the subtleties and peculiarities of any production simply because there is no education and relevant experience. This means that they cannot effectively manage the economy. And there is nothing to say at all about industrial policy, because they do not have an adequate vision of scientific and technological progress and its future, and they are not capable of formulating this policy in the interests of the country's economy. There is no content behind their loud words about "innovations", "energy efficiency", "increasing the competitiveness of production", "creating production with high added value". Therefore, we have problems with the industry. Even now, when, under the conditions of sanctions, competition in the domestic market is reduced, production in the country is falling! They, the current managers, would be silent and listen to what experienced specialists say. But just the latter are silent, and who asks them? And even if they say - who will understand them?

Today we are witnessing total incompetence and incompetence at all levels of government and administration. This is a disaster for the economy, that is, industry. Because cadres really decide everything. And today, more than ever, we need competent people in government. Such as Leonid Arkadyevich Kostandov. Only then can we raise the economy.

Whatever you say, but Soviet time able to work with staff. Looked at the success of leaders lower level, and if they proved by deed their capacity, their ambition in the good sense of the word, the ability to solve problems and work with people, then they moved up. It was a positive selection, a selection based on deeds, not words. In this sense, Leonid Arkadyevich is a classic example of a specialist who has gone from an engineer to the Minister of the Chemical Industry of the USSR. All of it professional life and fate is a series of continuous trials of increasing complexity.

It all started in Chirchik at the electrochemical plant, where in 1940 he was sent young specialist Kostandov, who graduated from the Moscow Institute of Chemical Engineering with honors. Here, the world's largest production of hydrogen by the electrochemical method was created using domestic equipment. In essence, Leonid Arkadyevich had to build this enterprise, master new equipment, train machinists and apparatchiks and start production. He passed this first test with honor, and in August 1941 he was appointed chief engineer of the plant, which now, when the war began, received the status strategic enterprise, - after all, it was used to make the substances necessary for the manufacture of explosives.

In the autumn of 1941, the State Defense Committee decided in as soon as possible to build two new workshops for the production of high-explosive aerial bombs with a new explosive at two chemical enterprises - the Chirchik Electrochemical Plant and the Kemerovo Nitrogen Fertilizer Plant. The deadline was one year.

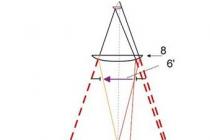

All design work completed by the State Institute of Nitrogen Industry (GIAP), and built by L. A. Kostandov. Then he proposed a daring, but, as it turned out, very correct decision - to build a workshop on two levels. The bodies of aerial bombs arrived at the upper one - here they were prepared for equipment. Then, along a special flyover, invented by Kostandov, the bombs descended to the first level, where they were filled with explosives. Moreover, to slow them down, and bombs are a heavy thing, Kostandov suggested using a rubber roller from the T-34 tank. This greatly simplified the process. Along the way, he reconstructed and improved the synthesis column nitric acid to make explosives. And in general, he demonstrated that he can solve and simplify technical problems. He did not get out of the workshop for days, and the workshop was launched exactly at the appointed time. The first echelon was loaded with air bombs marked “Object 215 of the Chirchik Electrochemical Plant named after. I. V. Stalin "on the night of January 1, 1943 and sent to the Kalinin Front. Then, in 1943, Kostandov received the first government award - the gratitude of the People's Commissar of the chemical industry M. G. Pervukhin.

Keeping this word and observing the stated deadlines, looking for the best technical solution that simplifies the technological process, spending days and nights in the workshop during commissioning so that nothing is missed - these are the lessons Leonid Arkadievich learned for himself and always adhered to these principles, even while holding the rank of minister of the chemical industry.

All 13 years that he worked at the plant in Chirchik were a daily battle with challenges and circumstances, a battle to introduce new technological processes as soon as possible. And every time Kostandov was the leader of the next project.

For example, heavy water. In the forties, the country urgently needed it for nuclear project. In 1944, the government set the task: make water, and already in the fall of 1945, the first workshop for producing heavy water by the electrochemical method was launched in Chirchik. A little later, a pilot plant was built here, where heavy water was made in a cheaper way - from deuterium obtained by low-temperature distillation of liquid hydrogen. The case is completely new, there were no analogues from which one could learn. And at first, distillation columns exploded one after another. For a long time they could not understand what was the matter. Kostandov got to the bottom of the matter.

He realized that the cause of the explosions was oxygen. Its small amounts, present in the initial hydrogen, solidified during distillation at a very low temperature (24–26 K), accumulated in the column packing, and provoked an explosion. Therefore, the process required high purity hydrogen - with an oxygen content of no more than 10–10 mole fractions. However, at that time we did not have oxygen analyzers of such high sensitivity, not only for factories, but even for research purposes. And then Kostandov, together with fellow engineers and designers, took up calculations and computational experiments. Thanks to them, it was possible to build a system in which the distillation column itself became an oxygen analyzer in hydrogen.

In 1949, Kostandov was appointed director of the Chirchik Electrochemical Combine. Why? After all, he was still quite young - a thirty-four-year-old engineer. Yes, because he has already managed to prove that he is capable of much, and most importantly, he knows how to take responsibility, bring things to the end and work with people.

Directorate for large enterprise, especially at the chemical one and at that difficult time, it was akin to sitting on a powder keg, and in the truest sense of the word. Shortly after Kostandov's appointment, an explosion occurred at the plant - an autoclave for the direct synthesis of nitric acid was torn to pieces, seven people were injured, one-story houses were demolished a kilometer from the plant. The local administration of the NKVD reported to Moscow that the entire plant had been destroyed and its entire staff had perished. The accusation of the NKVD of sabotage was repelled, but the true causes of the accident had yet to be sorted out. Academics and other specialists were called to help. It turned out that the explosion was provoked by dichloroethane that got into the autoclave.

Kostandov learned a life lesson from this accident. Meticulous attention to detail, reliability of devices, safety of personnel became his priorities - the priorities of the future minister. In general, chemical production teaches you to think about the consequences - a good skill for working in power.

For thirteen years in production, which constantly mastered new technological processes, Kostandov went through fire, water and copper pipes almost literally. They provided invaluable experience. This is the required competency-building professional school that any industry leader must pass to be effective. His honest work with full dedication was rewarded by the state with two prizes - the Stalin Prize (1951) for the introduction at its plant of a progressive technology for the gasification of low-grade coals in a fluidized bed, developed at the GIAP, and the Lenin Prize (1960) for a new industrial process for producing heavy water. And this was another impressive lesson for Kostandov - success can only be achieved in the union of production workers and industry science, and there is no other way of development.

Kostandov worked as a director for only four years. Of course, the Ministry of Chemical Industry wanted to get such a bright leader. And got it. In 1953, he was appointed head of the Main Directorate of the Nitrogen Industry, which he led for five years, then there was work at the State Committee for Science and Technology, in 1965 he became a minister.

The Minister came out of it that is necessary. The highest professionalism and competence, which he acquired in the first 25 years of his career, allowed him to quickly become the country's chief chemist. And not just a chemist. A mechanic, a scientist, an engineer, a marketer, a financier, an economist, and a politician simultaneously existed in it. With representatives of any of these professions, he spoke on an equal footing, and gave odds to many. He had a colossal authority in the industry, he was valued for his deep engineering erudition, wisdom, statesmanship, breadth of views and strategic vision of the future.

Everyone who worked with Kostandov notes his amazing memory - once he saw the installation, he accurately remembered its main parameters: the power of the unit, the number of reactors, productivity, hardware design and, most importantly, the people working on it.

His authority in the field of chemistry and petrochemistry was unparalleled not only in our country, but also in the world. He traveled a lot different countries to see new chemical productions, new technical solutions and products. And although the host companies hid their know-how, Kostandov saw through all the technological processes. Here is a typical story that happened in Italy, when our government delegation was shown the plant of the ENI concern. The head of the ENI concern leads a tour of the plant - look to the right, look to the left, he tells, skillfully omitting technical details. L. A. Kostandov delicately asks for clarification of the details and hears in response:

This is know-how...

In that case, - Leonid Arkadyevich retorts, - I myself will tell you about them.

And then he names the main parameters: pressure, temperature, process duration, output volume finished products... Needless to say, what a shock the Italian director had. It is unlikely that foreign colleagues have seen another minister who would have such a deep knowledge of all chemical processes and apparatuses, chemical production in general.

Despite the abundance of obligatory affairs of the minister, he continued to give out technical ideas and solutions that were picked up at the factories. For example, he insisted on obtaining chlorine by electrolysis under pressure in order to intensify the process. And not just insisted, but proposed specific new technical solutions. As a result, an original installation appeared, which was patented in the USA, England, France, Germany, Japan and other countries. Today, pressure electrolysis is used in the membrane process for the production of chlorine and pure caustic soda. Or at a meeting at the Redkinsky Experimental Plant, where they discussed technologies for purification and preparation of solvents, he suddenly began to ask the speaker questions from physical chemistry on phase equilibria and azeotropic systems, which amazed everyone present - and how does he know this?

Kostandov burst into the enterprise like a whirlwind. He came not to arrange a scolding, but to see everything with his own eyes, to support, inspire and help. It never occurred to anyone to offer him a guest route - he knew all the nooks and crannies of all the factories of the industry too well. He noticed everything, understood everything, talked to anyone, regardless of the hierarchy, instantly mastered the situation, no matter how difficult it may seem to others. And then, at a meeting in the director's office, he summed up the results in a quiet but convincing voice, formulated the decision clearly, not for a second doubting that it was correct.

In the early 1980s, when Kostandov was already deputy chairman of the Council of Ministers of the USSR, in a conversation with someone close to him, he said: "Our country will die from the incompetence of the authorities." Knew what he was talking about. Management efficiency is a derivative of competence. But not only. Competence breeds confidence, and confidence breeds conviction. Kostandov, with his reinforced concrete arguments, could convert any member of the government, any director and ordinary employee to his faith. He was incredibly persuasive and therefore could captivate, inspire and lead. He was incredibly effective because he knew the business thoroughly and clearly saw the goal.

What idea was this statesman committed to? What goal did you go to, step by step, conquering new heights? It is expressed in one short word - chemicalization.

Chemicalization

Today, polymers and plastics - an integral part of our daily lives, and the question does not even arise: “How could it be otherwise?” But some 60 years ago it was different. Then the arguments that new unusual polymeric materials, light, transparent, bright and durable, will fill our whole life, looked like a fairy tale, and against the backdrop of the then domestic industry - just an irresponsible fantasy. But the fact that this would be exactly the case was known by almost the only person in the government - L. A. Kostandov. He threw all his energy, organizational talent and eloquence into persuading the authorities: it is urgent to put the chemical industry on its feet and not spare money and effort for this, because it is it that will pull the entire economy of the country forward.

Kostandov not only understood and deeply felt unlimited possibilities chemistry, but with his knowledge he could break any skeptic. He never tired of repeating that “concern for chemistry is not an end in itself, not a matter of fashion or economic conjuncture. Chemistry and the chemical industry is one of the key positions productive forces any country. Without this, it is impossible to develop the oil, machine-building, electrical, electronic, light, Food Industry that define our economy."

And he convinced me!

Two extraordinary personalities, L. A. Kostandov and V. M. Bushuev, head of the Chemical Industry Department of the Central Committee of the CPSU, used all their influence on the country's leadership to create a chemicalization program. As a result, the May Plenum of the Central Committee of the CPSU in 1958 was devoted to a single issue - the development of Great Chemistry. After the Plenum, an extensive and unprecedented for that time state program for the development of chemistry and petrochemistry was adopted. In terms of scale and concentration of resources, this program can be put on a par with nuclear and space projects.

Kostandov and Bushuev rushed into this desert with such passion and energy that it began to bear fruit literally before our eyes. In the first seven years of the program (1959-1965), enormous funds were invested in chemistry for those times - 9 billion rubles. This is almost two and a half times more than in the previous 40 years. And in the next five years, funding increased by another one and a half times.

Kostandov, summing up the first results in 1967, noted that “the production of chemical products in the USSR increased by 2.5 times. Plastics and synthetic resins have been used twice as much in construction, three times more in mechanical engineering, three and a half times more in woodworking and the furniture industry.” That is, the intensive use of products of the chemical industry began in almost all sectors of the national economy.

This is the essence of chemicalization - to replace traditional materials (metals, wood, stone, natural rubber, wool, silk, cotton and linen), more expensive, more scarce, heavier and more labor-intensive, with new ones in numerous industries and its products. synthetic materials - light in weight, easy to process, more economical and cheaper to manufacture. “To oppose artificial to natural, plastics to metals, would be complete nonsense. Both are necessary for the national economy, - said Kostandov. - Plastics and metal coexist and complement each other. It's just that the costs for the development of plastics production are 100–150 times less than for metallurgy.” And where possible, it is necessary to replace scarce natural materials, because it is economically justified. In the same plastics industry, production costs are very low, and this industry has an almost unlimited supply of raw materials - natural gas and refined petroleum products.

Arguments in favor of chemicalization poured out of Kostandovo as if from a cornucopia. “Chemistry saves the national economy great amount labor and resources, and can save even more. Literally everywhere. Take food. One hundred years ago (in 1870. - Note. ed.) one person living in the village could feed another person in the city. And now from the same area, thanks to mineral fertilizers and plant protection products, it can already feed 13 people.”

“Get some clothes. Without chemical fibers today it would simply be impossible to clothe humanity. In 1969, four million tons of synthetic fibers were produced in the world. And wool - only two million tons. By the way, to shear this wool, you have to keep about a billion sheep. It turns out that chemists keep another two billion sheep in their apparatus.

"Replacing a ton of thin and semi-thin wool fabric synthetic fabric saves 10-15 thousand rubles (in 1970 prices. - Note. ed.). No less effective is the use of chemical materials in industry, construction, and transport. The point here is not only the replacement of scarce metals with plastics, but also a sharp decrease in the cost of manufacturing plastic parts instead of metal ones. In addition, plastic polymeric materials give industrial designers more freedom. In many cases, the creation of new machines and devices is simply impossible without new materials.

“The greatest savings in resources are when replacing alloyed steel, bronze, brass with phenolic press powders, styrene copolymers, polyamides, polyvinyl chloride, vinyl plastic, polypropylene. Such a replacement not only saves labor, but also gives machines new qualities: it reduces the weight of aircraft and machine tools, railway cars and ships, electronic equipment and cars. Let me remind you that in modern passenger car in the last 6-7 years the number of plastic parts has doubled and is now approaching 500.”

Indeed, the first Zhiguli cars that rolled off the assembly line in 1970 contained 34 kg of plastics. In 1983, the contribution of polymers was already 72 kg. For the near future, Kostandov predicted 90 kg and was not mistaken! Today modern car 30% consists of polymeric materials.

Let's take pipes. The replacement of metal pipes in the national economy with plastic ones - made of polyvinyl chloride and polyethylene - was on the agenda in 1979. According to calculations, in 1980 we needed about a million tons of polymer pipes. This made it possible to release 5 million tons of steel and save 10 million tons of oil annually. After all, the total consumption of heat and electrical energy for the production of polymeric materials four times less than for the production of steel, six times less than for the production of aluminum, five times less than for the production of copper.

In those years when the chemicalization program was unfolding (1959–1980), Kostandov was the central figure in the media space. Socialist Industry, Economic Newspaper, Izvestia, Pravda, Trud, Stroitelnaya Gazeta, Moskovsky Komsomolets - all regularly published interviews and articles by Kostandov, in which he never tired of talking about the essence of chemicalization, about her growing success. Leonid Arkadyevich spared no time for this work, because he believed, and quite rightly, that constant propaganda is a necessary part of any large-scale state program, the key to its success.

It was then, on the wave of chemicalization, that it was decided to create a popular scientific journal "Chemistry and Life". The first issue of our journal was published in April 1965, and L. A. Kostandov became a member of the editorial board, along with academicians. Without any ceremony, he came to the basement at 61 Leninsky Prospekt, where the editorial office of Chemistry and Life was located for a long time and where meetings of the editorial board were often held. He was always friendly, informative, open to any conversation, constructive. From the point of view of a journalist, Kostandov was an ideal source of information, because he answered questions quickly, to the point, immediately putting his thoughts into a literary form. Inarticulate speech and slow-wittedness, as well as arrogance and snobbery, were alien to him. It is not surprising that Kostandov's interviews and articles appeared in our magazine every year, or even twice a year.

I leaf through old newspapers and magazines, read his articles and physically feel the energy that comes from these texts. What a talented and strong man he was!

Of course, chemicalization did not develop in a single country. It was a global trend. In 1951–1975, world production of plastics increased 24 times, while steel production increased only 3.4 times; chemical fibers - 6.4 times, and the main natural fibers (cotton, wool, flax, silk) - 1.7 times.

The USSR integrated itself into the world process on time and very successfully and soon began to break into the world leaders in certain positions. Let's say production mineral fertilizers we overtook the US in 1973 and became the first in the world. At the same time, the share of complex and concentrated fertilizers was 84%. The Soviet chemical industry has taken second place in the world in terms of output. For twenty years, the production of plastics in our country has grown more than 14 times. By 1980, 300,000 standard sizes of plastic products were produced in the USSR. In the early 1980s, we were producing 80,000 chemical products based on oil.

All this required an investment of funds, and considerable ones. From 1961 to 1980, chemistry and petrochemistry in the USSR received about 58 billion rubles of capital investments. That's trillions by today's standards. The main production assets increased 10 times, the volume of gross output of the chemical industry reached 41.7 billion rubles in 1980. The average annual production growth rates in the chemical industry were on average 1.4 times higher than in the industry as a whole. Their share in the gross industrial output increased from 3.7% to 7.7% over 20 years.

At first, the growing chemical industry of the USSR primarily served agriculture and the military complex, which is understandable - the state must feed the people and protect them. But soon the turn came to everyday needs. The older generation remembers what a miracle nylon stockings were, and then tights made of polyamide fibers, nylon shirts. And the first transparent plastic bags? Mistresses washed and dried this miracle to use many times.

Every year, as the Great Chemistry became established, there were less and less skeptics. Now no one argued with what Kostandov said. And he said the following:

“Chemical science and the chemical industry complement the traditional set of natural substances used for centuries with artificial materials. And what is created by chemists is often superior to natural. It is very important. But that's not the point. The chemical industry, in comparison with other industries, makes the most complete use of the processed substance, energy, social labor. This is what makes the chemical industry one of the leading branches of the national economy.

It became clear that chemicalization is "an objective, necessary, inevitable process." In order to increase the efficiency of the national economy, it is necessary to increase the share of chemical products in it. The higher the level of chemicalization, the more powerful and technically perfect our national economy becomes.

Summing up the results of his fifteen years of activity as minister, Konstandov said: "A lot has been done, but there is still more to be done." Indeed, a lot has been done. In a matter of years, the USSR not only eliminated the backlog from Western countries in the chemical industry, but also became a leader. How did it happen?

Industrialization

The economy is like a wheel: as soon as it stops moving, it will fall. This applies to any industry, any production, and life in general. And chemicals, of course. Fortunately, “the possibilities of chemical science are endless. And therefore, the chemicalization of technology knows no limits, - Kostandov argued. “It is impossible, it is impossible to stop developing chemistry either in twenty years or in a hundred years.”

The idea of constant and continuous development was at the heart of Kostandov's tactics and strategy. But for development, an industrial base is needed, which had to be created. Then, in 1959, work on the chemicalization program began with deep analysis and planning. Moreover, the analysis of not only the experience and trends of the global chemical industry, but also the raw materials of our country, the needs of other industries. In general, chemical production is a complex thing. As Kostandov said in the mid-60s, “in order to establish the production of one new substance or material, it is required to create intermediate products for it. It turns out that one production pulls five to ten others. For example, to get impregnation for a bologna raincoat, you need to make 32 semi-finished products.

What is required for chemical production? Raw materials and energy. “Chemistry is an energy-intensive industry, and we are attracted to energy-rich regions,” said L. A. Kostandov. - Unfortunately, mineral deposits are not always accompanied by energy reserves. For example, not far from Moscow, near Ryazan, geologists have explored a magnificent complex of rock salt - but how difficult it is to find electricity for energy-intensive production here. It is known that the whole of Armenia is located on salt deposits and beautiful limestones - but their development is also limited by a lack of energy.

It just so happens that nature provides the greatest benefits - both energy and underground reserves - precisely in undeveloped "empty" areas. Here everything needs to be created anew, as was the case, for example, with the Yavan chemical plant in Tajikistan. This plant appeared, in essence, from scratch - there is no city there, no people. But there is a powerful power plant nearby - the Nurek hydroelectric power station. And in the vicinity of the hydroelectric power station, natural gas and huge deposits of rock salt were discovered. Here, over time, large-scale production of caustic, soda ash will be established. Thus, one after another, reference points appear on the map of chemistry.

Raw materials have always been Kostandov's special concern. Thus, assessing the prospects for the production of sulfuric acid, he clearly understood the insufficiency of the raw material base in Ukraine and therefore decided to develop sulfur mining in Turkmenistan, allocating the resources of his ministry for this. Then a whole chemical complex with advanced technologies was created there.

In the same way, Kostandov sought the commissioning of the richest Astrakhan gas complex. The gas produced here contains a lot of sulfur, due to which it was possible to increase the production of sulfuric acid, which is so necessary for various industries - for example, for the production of chemical fibers.

By the end of the 50s, Tataria came out on top in oil production, and in the 60s its production reached 100 million tons per year. But more than half of the resulting associated petroleum gas, which amounted to about 2.5 billion cubic meters per year, was flared simply because no one needed this gas. In other words, the most valuable raw materials flew into the pipe in the literal sense of the word. And then, on the initiative of Kostandov, it was decided to build the Kazan plant of organic synthesis and the Nizhnekamsk chemical plant.

In general, deep processing of oil, associated gas Kostandov perceived it as a personal problem, although this did not apply to his department - after all, the oil and petrochemical industries were under the jurisdiction of a separate ministry. But it was the processing of oil, associated and natural gas that provided food for Big Chemistry. And today, any thing made of polymeric materials, be it plastics, fibers or films, traces its history back to an oil well.

In 1977, with a group of scientists and specialists, Kostandov attended a conference on the chemical industry held by the Soviet-American Trade and Economic Council. At this meeting, Philips Petroleum President Leo John Stone shared this information. In 1977, the United States produced $50 billion worth of polymer and other petrochemical products. Oil worth $4.5 billion was used as a raw material for the production of these products. The obtained petrochemical products were processed into products, mainly polymer products, for the textile industry, automotive industry, Agriculture, transport. The total amount from the sale of these final products amounted to $ 500 billion, that is, 100 times more than the cost of the feedstock!

Kostandov liked this recalculation so much that later he often used it in his speeches, saying that "one ton of oil costs about a hundred dollars, and the chemical products of the same ton cost tens of thousands of dollars."

As for energy, then 10% of all generated energy was spent on meeting the needs of chemical industries in the USSR. That is why as new major centers Navoi, Tomsk, Shevchenko, Yavan and other cities were chosen for the chemical industry. Jobs were created around such energy-chemical complexes, cities grew. As a result, infrastructures changed in Armenia, Azerbaijan, Latvia, Lithuania, Belarus, Uzbekistan, Turkmenistan, Tajikistan, Ukraine, large industrial centers were formed.

Raw materials and energy are the key things for Big Chemistry. However, more factories are needed. At the time when chemicalization started, chemical engineering in the USSR was, to put it mildly, backward. This means that technologies and equipment had to be purchased abroad. The money allocated under the chemicalization program was clearly not enough for this, because Kostandov's plans were large-scale. Where can you get the currency to buy what you need in the West?

Kostandov knew how to find unexpected solutions to the most complex problems. He suggested and convinced the leaders of the country that new factories should be built with Western money on the basis of compensation agreements with leading foreign firms. For us - chemical plants, and for our partners - products manufactured on them. Agreements were prepared and concluded on the construction of the largest capacities for the production of polyethylene, polyvinyl chloride, polypropylene and other products. The compensation agreements, in particular, involved the well-known millionaire Armand Hammer, with whom Kostandov personally negotiated, very tough, it should be noted.

In this field, he made a lot of ill-wishers, envious people, and sometimes even enemies. A significant part of the prominent figures of the State Planning Commission met Kostandov's idea and his compensation agreements with hostility, not embarrassing to evaluate them as ruinous, and, naturally, put a spoke in the wheel with all their might. But a few years later, after the launch of the first production facilities on a compensatory basis - for example, capacities for the production of 200 thousand tons of low-density polyethylene - the country paid off for the purchased equipment and licenses in two years and was able to profitably export this product by creating a pipe production , containers and household products.

The supply of large quantities of chemical products for export as payment for processes and equipment has created serious transport problems. Transportation by rail was limited, as it required a rearrangement of wheelsets on the border with Europe - the Russian gauge is almost ten centimeters wider than the European one. IN seaports there were no terminals and containers for the accumulation and shipment of goods. And only under one agreement with Occidental Petroleum, it was necessary to ship more than 5 million tons of ammonia and phosphoric acid.

Kostandov, as often happened, took the problem upon himself - he decided to build two ports at the expense of the Ministry of Chemical Industry, in Ventspils and Odessa. Simultaneously with the construction of the Odessa port, an ammonia pipeline was laid to it from Togliatti, where several plants were being built to produce ammonia. Occidental has pledged to buy 3-4 million tons of ammonia and ship it by sea. Over time, the terminals for the export of other chemical products were also expanded.

Another fruitful idea of Kostandov is international cooperation. It is clear that it was possible only with the CMEA countries, primarily with the GDR, Hungary and Poland, but this was more than enough. So, by 1985, we received 43 units for the production of sulfuric acid from Poland, each with a capacity of 400-500 thousand tons per year, from Czechoslovakia we were supplied with components for ammonia plants, from the GDR came equipment for plants for the production of chlorine, chemical fibers and many other substances and materials.

Kostandov, together with fellow ministers of the socialist countries, planned a very reasonable division of labor and a unified chemical map for the CMEA countries: energy-intensive industries were located on the territory of the Soviet Union, and fine chemistry developed in the CMEA countries - in particular, in Hungary and the GDR. Cooperation in the field of obtaining chemical reagents was especially extensive, which made it possible to provide the electronic industry of the USSR with everything necessary.

Together with chemists from the GDR, we created high-capacity units (at least 50 thousand tons per year) for the production of high-density polyethylene. In 1975, the first pilot plant "Polymir-50" was put into operation in Novopolotsk. By the way, the numbers in the names of the installations just indicated their power. And then, under the same name, they built a series of similar installations in Sumgait and Tomsk, at the Leinaverke industrial plant in the GDR, and also sold the license to the West German company Salzgitter.

In general, Kostandov used the principle of creating joint international teams for projects many times - to develop processes for the production of chemical fibers, fiberglass, polymeric materials, etc. It is amazing how many Western companies, research, design and industrial, orbited around Kostandov. There was no talk of any "iron curtain".

Judge for yourself the scale of work on compensation agreements and international cooperation. From 1960 to 1986, thanks to Western technologies, purchased licenses, equipment, installations, about 1,200 large-scale chemical and petrochemical industry facilities were built and launched in the USSR. The total cost of these purchases amounted to about $15 billion. In the 1970s and 1980s, 50% of the entire equipment fleet was imported. It produced 90% polyethylene, 100% propylene, 60% polyvinyl chloride, 78% ammonia, 70% methanol, 68% sulfuric acid.

Big chemistry quickly gained momentum. Already in the mid-60s, Kostandov said in his interviews that “a real taste for chemistry appeared, the industry believed that it was profitable to use chemistry. But we can't meet all the needs yet. According to our calculations, the chemical industry needs to develop with an annual increase of 18-20%. This means that for every 1% growth of all industrial output in the country, there should be 2% growth in the chemical industry.” Therefore, it is necessary to increase labor productivity and production efficiency. Again, a daunting task. How to solve it?

“One of the clearest ways is to enlarge production units,” said Kostandov. - Instead of 10 units, you put one 10 times more powerful. And the number decreases accordingly. service personnel. But this one unit must work flawlessly, the system must be absolutely reliable. I argue that without absolutely reliable equipment it is impossible to increase labor productivity by several times. And it's not just the units themselves. How many people we have in the repair and technical services, in the workshops of instrumentation! With reliable equipment and warranty service by the manufacturer, these services are not needed at all. This is the fundamental question of economics.”

And again, Kostandov was the first to raise a key issue in the development of the industry - the need for units of large unit capacity. Not because he so wanted to, but because he saw a need for it - the demand for products of Great Chemistry was growing rapidly. For example, in the 60s it became clear that there was not enough polystyrene for the manufacture of home refrigerators, electrical products, household appliances, radio and television equipment. All of our production at the Kuskovsky chemical plant and the Gorlovsky plant, where there were units for 1-1.5 thousand tons of polymer per year, could no longer meet the demand in the domestic market. It was necessary to radically improve the synthesis and sharply increase the productivity of the installations.

The same applies to polyvinyl chloride. “Reactors with a capacity of 5-6 thousand tons cannot solve the problem of a sharp expansion of polyvinyl chloride production,” said Kostandov. - We need new powerful units with a capacity of 100-200 thousand tons. This means that we want to reduce such plants as Severodonetsk, Novomoskovsky, Chirchiksky, Nevinnomyssky and many others to a single unit. That is, instead of 20 synthesis columns in Novomoskovsk or 20 compressors in Severodonetsk, we want to supply one column or one compressor.” Again, new technologies, new devices were needed. Construction again.

Ignoring accusations of megalomania, he achieved the construction of an order of magnitude more powerful plants for the production of ammonia, polyethylene, polyesters and other large-tonnage products.

In the case of polystyrene, he himself suggested that the scientists and specialists of the Kuskovsky Plant and the Leningrad Institute of Polymerization Plastics switch from the method of complete, almost 100 percent, conversion of styrene to the method of incomplete conversion. This really made it possible to efficiently use the heat of reaction and design units with a capacity of 15–20 thousand tons per year. And now in Dneprodzerzhinsk built new plant to produce polystyrene with a capacity of 85 thousand tons, even more large factories appeared in Omsk and Shevchenko. The country ceased to depend on the import of polystyrene, and the chemical industry fully met the needs of the national economy in this polymer and was even able to partially export it.

This policy has fully justified itself, and it is on installations of this type, which consume little energy, that we still produce competitive products for export.

In the chemical industry under construction for the period from 1961 to 1975, the state invested 15.5 billion rubles (in those old money). That's where the current officials would roam. But then this money was spent honestly and wisely. The efficiency of public investment by today's standards has been fantastic. In 1971-1975 alone, more than a thousand new production facilities were put into operation in the chemical industry. So Big Chemistry has become the most important base for almost all industries. material production, has become the main supplier of materials for heavy and light industries. Rocket and space technology, nuclear power plants, plastic buckets and tights - they are all children of Big Chemistry. And even today, 90% of the chemical products exported from Russia are produced at installations created under Kostandov.

The science

Who is the ideal chemist? This question "Chemistry and Life" asked Kostandov in 1976. Here is what he answered: “The ideal chemist, first of all, should be creative in nature, able to generate new bold ideas, to see the meaning hidden from others in the behavior of substances, in their properties. I would compare an ideal chemist to a talented composer. One of the chaos of sounds builds melodies, finding perfect harmony. The other harmonizes the world of elements and, obeying the laws of nature and intuition, combines substances in combinations that had never occurred to anyone before. But if you always want to hear a composed melody in a good performance, then the ideal chemist will certainly be expected to give clear recommendations on the practical implementation of his ideas.”

Without science, a strong industry cannot be built. Kostandov was convinced of this and did not get tired of repeating that "any new scientific work that has been put into practice improves either the quality of the product or the efficiency of the process." This is exactly what our economy needs.

“Every scientist should strive to see in his work the features that make it necessary for practice,” said Kostandov. - To see and show to others, to prepare the work for implementation. By the way, Kostandov did not like the word "implementation", which carries a connotation of violence. He was more inclined to the interpretation of academician Yu. A. Ovchinnikov - not to implement, but to trust the development of industry.

Kostandov equally valued both fundamental and applied science and did not particularly share them. Science is science. He believed that the development of chemistry is one of the main directions of the world progress of science and technology. Statements that belittled the role of people working in the field of fundamental science, and this was the case in the 70s, he was not only surprised, but outraged, although he himself was engaged in purely practical affairs. And when he spoke about the successes of chemicalization, he always repeated that “the achievements of industry are based on the successes of Soviet science, on the research and discoveries of such outstanding scientists as N. D. Zelinsky, N. S. Kurnakov, A. E. Fersman, N. N. Semenov, A. N. Nesmeyanov, V. A. Kargin, K. A. Andrianov, S. I. Volfkovich, N. M. Zhavoronkov, G. K. Boreskov, I. V. Petryanov and others.

“Let's say Academician Petryanov worked on aerosols and aerosol filters in a purely theoretical sense,” Kostandov said. - But aerosol filters are in dire need of the industry. And they immediately began to release, although, believe me, no one introduced anything in the accepted meaning of the word. We literally followed the scientists and got them to answer the questions that interested us.”

By the way, all the listed people are academicians involved in fundamental research. In general, the former academicians did not suffer from snobbery, did not talk about pure fundamental science and did not dismiss the production workers - they say, this is not for us, this is for applied workers, we are engaged in high science here. Following the behest of D. I. Mendeleev “science should serve for the benefit of the people,” they considered it an honor to cooperate with industry. “When in the post-war years we mastered cryogenic processes based on the work of Academician Kapitsa, we did not experience any particular difficulties. If any question appeared, then Kapitsa immediately explained it to us on his diagrams, ”Kostandov recalled.

But of course, engineering work, design work is a special kind of activity, without which the industry cannot live. Therefore, Kostandov made enormous efforts and created a powerful branch of science - new research institutes, new design bureaus and design organizations, new pilot plants. By the beginning of the 1980s, 400,000 engineers and technicians worked in the chemical industry, and in research And design organizations and at pilot plants - about 150 thousand people.

Each sub-branch of Big Chemistry, and there were eighteen of them, had its own research and design base. Polymer chemistry alone, for example, had major institutes in Moscow, Leningrad, Vladimir, Kemerovo, Polotsk, Donetsk, Rostov-on-Don, and other cities. Little is left of this golden fund today, therefore, in the field of scientific research in polymer chemistry, our country has been thrown back decades.

Expenses for science in the system of the USSR Ministry of Chemical Industry were comparable to the funding of the Union Academy of Sciences as a whole. Moreover, Kostandov insisted on consolidating the scientific forces of the industry with academic and university science. It was at his suggestion that branch laboratories appeared in universities, and research programs were formed annually together with the Academy of Sciences of the USSR and the Union Republics.

It is impossible to recall that a more or less significant meeting was held without the participation of leading experts. At almost every meeting of the collegium of the ministry, the work of one of the branch institutes was considered. Moreover, on the initiative of Leonid Arkadyevich, a corps of chief chemists was created in the ministry, who became permanent advisers to the minister, who, like the chief engineers of projects, were endowed with broad powers. The chief chemists regularly met with Kostandov - both individually and at meetings, when they discussed complex and hot topics, for example, the program for creating spaceship reusable "Buran". Each of the chief chemists tried to look more convincing, to make their contribution to the overall development of the topic more weighty, and customers from the industry were looking at who to work with further on this program.

All this, of course, played a positive role in the industrial breakthrough: in 1971–1985, the growth rate of chemical production was 1.5–1.7 times higher than the growth rate of the entire industrial output of the country.

In the chemical industry, more than 50 institutes were engaged in collecting and summarizing information about what chemical products and products are needed by other industries and ordinary consumers. We carefully followed everything that was going on in the world, we were interested in the areas of application of new chemical products abroad. Thousands of people took part in this serious work. Without it, it was impossible to answer the most important question of economic strategy: how to develop the chemical industry in the right way? The need of all sectors of the economy for products of Great Chemistry, studied at the institutes, became the canvas on the basis of which Kostandov and his colleagues compiled perspective plan development of the chemical industry.

Kostandov carefully kept track of what was new in the West. Often he tried to create new materials and technologies by analogy with Western models, relying on his branch science. That is, where it was possible to do without the participation of the West, he did it. He was convinced that if there were no the latest technologies, then we must try to reproduce Western ones on our own. There are many stories on this subject.

So it was in 1967, when Kostandov returned from the World Exhibition in Montreal, where the process of obtaining high-impact polystyrene by the incomplete conversion method was demonstrated. Leonid Arkadievich already in Moscow drew an approximate technological scheme and asked industry planners to try and design a 1,000 tonne per year pilot plant, promising their full support. Done! They designed, built and launched a pilot plant in two years.

In 1967, after the conclusion of an agreement between VAZ and the Italian Fiat, special polymers were required. One such polymer was DuPont's delrin. Kostandov summoned director Kuskovsky chemical plant, showed details from delrin and asked: "Can we make the same ones so as not to pay the currency?" - “We can,” the director replied, “give six months to the deadline, and we will give a polymer that is not inferior to delrin.” The plant kept its promise. The new polymer, called SFD, was created together with scientists from the Institute of Chemical Physics of the Academy of Sciences of the USSR and the Research Institute of Polymer Materials (NIIPM). Kostandov came to the plant more than once, asked how the work was going, went to the laboratories, to the installations, arranged meetings, gave helpful tips. The main result is that Fiat accepted our polymer instead of delrin for the production of Zhiguli.

When our developers produced something superior to Western analogues or something new in general, Kostandov always demanded that these products be brought abroad. This was the case with new diaphragm-type plants for the production of chlorine. They were superior in power to foreign counterparts and consumed less electricity. Soon Romania, Bulgaria, Poland began to buy them, negotiations began with French firms regarding the sale of a license.

Who set tasks for branch science? Of course, industry and the state represented by Kostandov. He regularly spoke to scientists with reports on the tasks of scientific and technological progress in the chemical industry. These were tasks with a perspective of 5–20 years. But he dreamed of a distant future, which was a mystery to him. “How to do such a thing: to gather scientists so that they themselves formulate problems that should be solved? May it be in the near future, albeit in the distant future. Let it even be fantasies, as long as it is theoretically possible. If only it wasn't a perpetual motion machine..."

Control

Kostandov's life fell on the Soviet era. He worked in the socialist economy and did not grieve about this, although he very often went abroad, saw western experience. Yes, he often scolded the order prevailing in the national economy, deeply experienced incompetence senior leaders, but admitted that Great Chemistry owes its success precisely to socialism. He believed that the possibilities of the socialist system were inexhaustible: “There is no such degree of concentration of the industry as in the Soviet Union in any country, and cannot be. We made good use of this opportunity. Planning opportunities - no. In other words, it is not socialism that is to blame, but we.

Here, for example, one of the problems is the unwillingness of enterprises to master new ideas and technologies. “There must be an economic mechanism in which innovation would be beneficial to the enterprise. And now it's the other way around! For example, to switch to the production of a new, more profitable product, the plant needs a month. But for this month he will not produce so much old products - and will not fulfill the annual plan. And no matter how he makes up for profit next year, no one will return the bonuses that the team lost for not fulfilling last year's plan. This means that it is necessary to give the plant the opportunity to regulate its work not only by the line of the annual plan, but also on an accrual basis. This is one of the necessary changes in the planning system.”

Like many other things, the planning of capital investments went topsy-turvy: the ministries and departments submitted quite reasonable, balanced proposals to the State Planning Commission. Gosplan, on the other hand, often crippling what was dictated by real needs, somehow brought them together, after which it submitted them for consideration to the Central Committee of the CPSU, and from there the projects returned over and over again for rework, because, according to the party apparatus, there were low growth rates of production volumes, labor productivity, efficiency of capital expenditures, etc., etc.

In such an environment, it was damned difficult to ensure any harmonious development of the industry. Meanwhile, it was Kostandov who did it better than other ministers. Exuberant and impetuous, he was able to restrain, laconic, with amazing patience and rare power of persuasion to prove his case, turning opponents into allies and thereby reducing countless flaws in planning.

He, being a realist, to the best of his ability, and often beyond that, straightened the crooked mirrors of the socialist economy. Therefore, without any exaggeration, we can say that our chemical industry often worked successfully not thanks to, but in spite of the system, and these successes should be attributed to the personal merits of Leonid Arkadyevich.

Once in a very high official meeting (the ministers of the socialist camp, now defunct CMEA) met, Leonid Arkadievich told an Italian story. A believer addresses the priest: “Padre, I smoke a lot, I can’t stand it without a cigarette. Is it not allowed to smoke during prayer?” The priest waves his hands: “What are you, my son! No way, be afraid of God! But think - maybe you should pray while smoking?

Probably, the ministers did not really understand what Kostandov wanted to say by this, although they laughed. And this joke very accurately characterized the time when the “right” words were more important than the deed itself. Kostandov understood all this very well. He was not at all a cold cynic and, it seems, sincerely believed that if there were versatile educated, talented people in the leaders of our state, everything would have gone completely differently.

The success of Kostandov as a manager lies not only in his deepest competence, but also in the fact that he loved and appreciated people. “To learn how to make beautiful things, you need to love people,” said Leonid Arkadyevich.

He used the principle “cadres decide everything” in his work daily and hourly. Visiting chemical enterprises in different parts of the country, he kept an eye on the directors, chief engineers, heads of industrial departments of regional committees - what could he do, what were the successes. The best, whose scale and potential were clearly greater than the regional ones, were taken to Moscow, appointed as their deputies, or appointed to another position of the allied scale. So it was with Sergei Viktorovich Golubkov, chief engineer of the Volgograd Chemical Plant named after. S. M. Kirov and the head of the department of the chemical, oil, gas and microbiological industry of the Volgograd regional committee of the CPSU. In 1977, Kostandov offered him the position of his deputy. He gave S.V. Golubkov the management of all special chemistry of the Ministry of Chemical Industry, and this was a gigantic site - at that time 51% of all the production of the ministry was intended for military enterprises working for defense.

So it was with Yuri Mikhailovich Luzhkov, whom Kostandov spotted at one of the industry meetings at the Research Institute of Polymers. The young specialist Luzhkov (he was then twenty-three years old), who worked at the NIIPM as a senior engineer, after that memorable meeting, approached Minister Kostandov and asked: “Why did you call the meeting if you arrived at it already with turnkey solution? “Yes, I came with a ready-made solution,” Kostandov confirmed. - But it was important for me to make sure that I and the representatives of the industry have the same understanding of the tasks, that there are no discrepancies and contradictions. Convinced." Soon Kostandov took Luzhkov to his ministry and appointed him head of the automation department. And then, when a young specialist in a couple of years got used to and got used to the ministerial corridors, learned the first lessons of Kostandov, the minister directed him to a really big new business - the creation of the country's first experimental design bureau of automation - OKBA "Khimavtomatika".

And once again Kostandov was not mistaken in his choice. Very quickly, on the wasteland on Selskokhozyaistvennaya Street, OKBA buildings grew up, in a matter of years, 21 branches of Khimavtomatika opened and began to work throughout the country - enterprises that employed 21,000 employees, candidates and doctors of science. It was here that modern sensors were developed and created to control all conceivable parameters of industrial chemical processes, the first in the country automated systems process control (APCS). And all this is the merit of Yu. M. Luzhkov, a student and like-minded person of Kostandov. Together they began to automate the chemical industry, and then this process spread to other industries, so here Kostandov and his team were the first.

These are just two examples. There are many more stories like this. Everyone whom Kostandov took to his "general staff" were not random people, but selected, one-piece personnel with great potential. For many years they worked together, and there was no staff turnover at the Ministry of Chemical Industry.

Kostandov not only loved and understood people, but he knew how to build good and productive relations with everyone - from an apparatchik to the prime minister. Actually, this is the art of management. Good relations have never harmed the business, and for the chemical industry they were vital, because the chemical industry is an extremely complex structure. Great chemistry needs raw materials, which means that close and effective interaction with the extractive industry and petrochemistry, which was then under the jurisdiction of another ministry. Big chemistry needs energy, which means interaction with power engineers. Machines and apparatus are needed, so cooperation with machine builders is indispensable. Of course - the builders, which means - the Ministry of Industry, the Ministry of Construction, the Minmontazhspetsstroy. We need transportation for raw materials, semi-finished products, finished products...

Kostandov was able to link all industries into a single scheme and make it work smoothly. He was able not only because he had a sharp analytical mind and systemic thinking (thanks to education!), he burned with the idea of chemicalization and was a manager of the highest qualification with gigantic successful experience behind him. But also because in his work he always relied on people - his colleagues, like-minded people, associates. Leonid Arkadyevich was not a lone warrior. He created a kind of party of like-minded people, bringing together professionals from various management levels, which made chemicalization possible in the USSR (see sidebar).

"Chemization Party" 1965–1984

The entire state system. The principal strategic decisions were made by the Central Committee of the CPSU. These local decisions were supported and promoted by departments of chemistry, specially created in the republican Central Committee and regional committees in regions with high potential chemical development. The Council of Ministers of the USSR and the State Planning Commission provided for the chemicalization program necessary resources. And the Ministry of Chemical Industry with its apparatus, which coordinated the work of 18 sub-sectors, hundreds of enterprises, industry research institutes, design and engineering bureaus, with the support of trade unions, brought the ideas of chemicalization to life. We can say that in 20 years Kostandov's "Party" was formed, the only goal of which was chemicalization for the benefit of the country. It is impossible to list all. Nevertheless, we considered it necessary to name at least the most important participants in chemicalization in various management groups.

Top leadership of the country

A.N. Kosygin, Chairman of the Council of Ministers of the USSR (1964–1980)

N.K. Baibakov, Deputy Chairman of the Council of Ministers of the USSR, Chairman of the State Planning Committee of the USSR (1965–1985)

V.M. Bushuev, Head of the Chemistry Department of the Central Committee of the CPSU

V.Ya. Isaev, First Deputy Chairman of the State Planning Committee of the USSR (1966–1984)

Ya.P. Ryabov, First Deputy Chairman of the State Planning Committee of the USSR (1979–1983)L.V. Smirnov, Deputy Chairman of the USSR Council of Ministers for Defense Industries, Chairman Military Industrial Commission USSR Council of Ministers (1963–1985)

D.F. Ustinov, member of the Politburo of the Central Committee of the CPSU, Minister of Defense of the USSR (1976–1984)Ministers

S.A. Afanasiev, Minister of General Mechanical Engineering (1965–1983)

V.V. Bakhirev, Minister of Mechanical Engineering (1968–1987)

K.N. Brekhov, Minister of Chemical and Petroleum Engineering (1965–1986)V.V. Listov, Minister of Chemical Industry (1980–1986)

P.S. Neporozhny, Minister of Energy and Electrification (1962–1985)

S.A. Orudzhev, Minister of the Gas Industry (1972–1981)

N.S. Patolichev, minister foreign trade (1958–1985)

P.S. Pleshakov, Minister of Radio Industry (1974–1987)

E.P. Slavsky, Minister of Medium Machine Building (1965–1986)

F.B. Yakubovsky, Minister of Assembly and Special construction works (1965–1975)

Science - academics

A.P. Alexandrov, N.S. Enikolopov, N.M. Zhavoronkov, B.P. Zhukov, I.L. Knunyants, G.I. Marchuk, Yu.A. Ovchinnikov, I.V. Petryanov-Sokolov, N.A. Plate, M.G. Slinko

"General Staff" - Deputy Ministers of the Chemical Industry

L.A. Kostandova, S.V. Golubkov, V.E. Koval, M.M. Milyutin, A.A. Novikov, N.P. Svettsov, Chairman of the Central Committee of the trade union of chemists, S.M. Tikhomirov, B.S. Ushakov, K.K. Cherednichenko, V.L. Yunitskiy

"Active" - heads of main departments, directors of enterprises, research institutes and design institutes, educational universities

M.S. Akutin, V.K. Andreev, S.A. Astvatsatryan, M.B. Bakirov, I.M. Barsky, N.I. Basov, E.P. Batova, L.B. Butovsky, M.S. Vardanyan, V.S. Getmantsev, D.V. Gorbovsky, P.F. Dobrynin, N.I. Doctorov, S.E. Dorokhin, V.V. Zhuravlev, V.S. Zaitsev, A.A. Zuev, V.P. Ivanov, K.Kh. Kadogly, M.Z. Kaidanov, V.I. Candela, V.M. Kataev, A.K. Kirillov, V.K. Kislitsin, G.A. Kostandova, V.I. Lapshin, Yu.M. Luzhkov, V.A. Lushnikov, A.I. Malchevsky, L.G. Marakhovsky, A.N. Melkumov, V.P. Merkulov, I.N. Mormylev, A.I. Nesterenko, V.M. Niyazov, L.V. Novozhilov, E.A. Panteleev, A.G. Petrishchev, I.I. Porzhitsky, V.M. Popov, A.M. Rabinovich, V.M. Romanov, V.F. Rostunov, E.A. Ryabenko, M.P. Sedov, V.P. Semenov, V.M. Serenkov, G.V. Smirnov, A.M. Khlebnikov, L.K. Khudoyak, Z.S. Tsakhilov, M.K. Chistyakov, L.S. Shevikin, V.F. Shilov, I.G. Shimko, V.S. Shpak, N.Kh. Yusupov

Apparatus of the Department of Chemistry Central Committee of the CPSU

Yu.V. Borodkin, K.A. Zakharov, G.I. Ivlev, L.K. Nedelko, B.S. Semenov, V.S. Smirnov

Office of the Ministry of Chemical Industry

G.F. Artemiev, A.I. Boldyreva, N.Ya. Varakin, K.F. Vinogradov, A.I. Zlobin, I.A. Lisenko, F.P. Natarov, M.P. Fedorova, A.K. Chernyshev

Kostandov understood that tomorrow's cadres go to school and institutes today, therefore, despite his enormous employment, he agreed to give a course of lectures on Saturdays "Scientific and technological progress and state of the art chemical industry" at the Academy of chemical protection. It was a cascade of bold and progressive statements, a firework of information about advanced foreign technology from the USA, Japan, the FRG, and Canada. Once, at one of the lectures, he brought a sheet of graph paper, on which the territory occupied by the Kemerovo nitrogen-fertilizer plant was depicted on a scale, and in the corner of this diagram there was a small square. It showed the area that modern units of large unit capacity would occupy with the same production plan. At lectures, listeners hung on his every word and many years later spoke about the deep impression that he made on them.

Yes, he could captivate, ignite, conquer with the scale of his plans. Everyone who was involved in the maelstrom of his ebullient activity felt like participants in exceptional, grandiose events. And it gave strength.

Leonid Arkadyevich knew how to work with people, trust them, and forgive inevitable omissions. The atmosphere of exactingness and goodwill that he created around him was amazing. He instructed his assistants: study projects deeply, get to the bottom, do not make rash decisions. Being himself a continuous generator of ideas, he knew how to listen, quickly grasp the rational and, most importantly, bring what was accepted to its logical conclusion.

He demanded from the leaders of any department of the ministry or enterprise the ability to think and make decisions independently, he could not stand inaction, fear of responsibility, indecision of his employees. He often repeated: “Do not run away from the problem, from the difficulty, go towards it, solve it. You will run away, she will catch up with you and dump you. Don't be afraid to decide." And one more thing: "Extremeness is now more useful than timidity, which can lead to technical backwardness." He never made a fuss over the wrong decision of any technical or organizational problem, but tactfully corrected, could transfer the topic to another or close it altogether. But he always did it delicately, without degrading the dignity of the employee. All his deputies tried to do exactly the same, and gradually the apparatus of the ministry became not a bureaucratic rigid mechanism, but a thinking governing body, in which many interesting people worked - analysts, non-standard-minded specialists.

In his daily work, the principle of personal responsibility of a person for an assignment was clearly visible. Therefore, he often met not only with leaders, but also with ordinary employees of the apparatus of the ministry, enterprises and institutions. Leonid Arkadyevich always controlled the fulfillment of his orders and orders - but not by reading the certificates compiled by the staff of the apparatus, but by communicating with the executors. He made hundreds of phone calls a day, and the industry knew that everything was under the control of the minister.

Kostandov has always been accessible and democratic. The memory of Leonid Arkadyevich was phenomenal. When talking on the government phone with senior leaders, he never used the records, he knew all the numbers by heart. He often called many factory workers and apparatchiks by their first names and patronymics, asking what had changed since the last meeting, how was their health, how was their family, what were their worries, how could they be helped...

During business trips, he always carried a voice recorder in his pocket and slandered orders to him with the deadlines for their implementation, which he gave on the spot. Then the records were deciphered in the ministry and orders were taken under control. Everyone was amazed at his poise when sorting out major problems. He never raised his voice, and that's probably why the guilty didn't hide anything. They knew that Kostandov could forgive a lot, but not lies and varnishing of events.

The craving for superiority, for experimentation, for the new was characteristic of him. business style which he brought up from his subordinates. From business trips abroad, Kostandov brought many samples of products, the production of which he dreamed of establishing in our country. And when he did, he was truly happy.

Every day and every hour, he taught employees how to work, by example. He didn't read lectures and rarely raised his voice. The sense of humor never left him. Always simply, on an equal footing with people, regardless of their positions and titles: no arrogance, no pressure with their authority; interrupted the interlocutor only when he was talking nonsense, but even in this case he was calm and reserved. Against the background of the seemingly generally accepted simplicity of morals that prevailed in the industrial, and even in the scientific environment, in the presence of Leonid Arkadyevich, everyone suddenly began to speak in pure literary language. Next to him, an inveterate boor became an intellectual.

Kostandov spent 12 hours a day in the service, after which he continued to work at home as well. And it is not clear how he managed to find time to read fiction, visit theaters, go hunting, meet friends. How did he do it all?

Kostandov's employees heard from him more than once: "Don't think that I'm smarter than you, I just sit higher and see further." This, of course, is not entirely true - he knew and could do more, and therefore did a lot for the country. By the beginning of the 1980s, he had created a world-class chemical industry that was firmly on its feet, which had its own engineering and scientific personnel, its own chemical engineering and its own instrumentation. Kostandov intended in the coming years to achieve the best world performance in both capital investment, and in terms of resource saving and production cost. Another ten years, and then no restructuring would have broken this steadily developing industry. But something happened that always happens in life - on September 5, 1984, L. A. Kostandov died, a year before his seventieth birthday.

Last lesson

The professional activity of L. A. Kostandov, the minister and chief chemist of the country, provides a wealth of material for study, learning, and imitation. But, as Kostandov said, “it’s not enough just to know a thing, you must also be able to do it.” He knew and knew how.

In preparing the article, interviews and articles by L. A. Kostandov in the journal "Chemistry and Life" in 1965-1983, in the media of the 60-70s, as well as fragments of memoirs of friends, colleagues and associates of L. A. Kostandov, published in the collection “Leonid Arkadyevich Kostandov. Minister, Engineer, Man” (Russian Chemical Society named after D. I. Mendeleev, 1996).

Federal Office for the Safe Storage and Destruction of Chemical Weapons (FUBHUHO)

federal state autonomous institution"Resource Center for Universal Design and Rehabilitation Technologies" (FGAU "RTsUD and RT")

(Ministry of Industry and Trade of Russia) - the federal executive body of Russia, which performs the functions of developing state policy and legal regulation in the field of industrial and military-industrial complex, as well as in the field of development of aviation technology, technical regulation and ensuring the uniformity of measurements, as well as the functions of the authorized federal executive body authority exercising state regulation foreign trade activities. Created May 12; in April-September there was a department with the same name and similar powers.

Story

All-Union ministries of the USSR

- USSR Ministry of Electronic Industry (MEP) (1965-1991)

- Ministry of the Oil Industry of the USSR (Minnefteprom) (Ministry of the Oil and Gas Industry of the USSR) (1939-1991)

- Ministry of Gas Industry of the USSR (Mingazprom) (later Ministry of Oil and Gas Industry of the USSR)

- Ministry of Aviation Industry of the USSR (Minaviaprom, MAP)

- USSR Ministry of Automotive Industry (Minavtoprom)

- USSR Ministry of Foreign Trade (Minvneshtorg) (later Ministry of Foreign economic ties THE USSR)

- USSR Ministry of Mechanical Engineering (Minmash)

- Ministry of Mechanical Engineering for Animal Husbandry and Forage Production of the USSR (Minzhivmash)

- Ministry of Mechanical Engineering for Light and Food Industry and Household Appliances of the USSR (Minlegpischemash)

- Ministry of Medical Industry of the USSR (Ministry of Medical and Microbiological Industry of the USSR) (Minmedprom)

- Ministry navy USSR (Minmorflot)

- Ministry of Defense Industry of the USSR (MOP)

- Ministry of General Mechanical Engineering of the USSR (Minobshchemash)

- USSR Ministry for the Production of Mineral Fertilizers (Minudobreniya)

- Ministry of Instrument Engineering, Automation Means and Control Systems of the USSR

- Ministry of Industry of Communications of the USSR

- USSR Ministry of Railways (MPS)

- USSR Ministry of Radio Industry (Minradioprom)

- Ministry of Rubber Industry of the USSR (Minrezinprom)

- USSR Ministry of Fisheries (Minrybkhoz)

- USSR Ministry of Medium Machine Building (Minsredmash) (later Ministry nuclear energy and Industry of the USSR (MAEP))

- USSR Ministry of Machine Tool and Tool Industry

- Ministry of Construction, Road and Municipal Engineering of the USSR (Minstroydormash)

- Ministry of Construction in the Far East and Transbaikalia (Ministry of Construction in the Eastern Regions of the USSR) (Minvostokstroy)

- Ministry of Construction in the regions of the Urals and Western Siberia USSR

- Ministry of Construction in the Northern and Western Regions of the USSR

- Ministry of Construction in the Southern Regions of the USSR

- Ministry of Construction of Metallurgical and Chemical Industry Enterprises (Minmetallurgkhimstroy)

- Ministry of Construction of Oil and Gas Industry Enterprises of the USSR

- Ministry of Construction of Fuel Enterprises of the USSR (MSTP)

- Ministry of Construction of Power Plants of the USSR

- Ministry of the shipbuilding industry of the USSR (Minsudprom)

- USSR Ministry of Tractor and Agricultural Engineering

- USSR Ministry of Transport Construction (Mintransstroy)

- Ministry of Heavy, Energy and Transport Engineering of the USSR (Mintranstyazhmash)

- Ministry of Coal Industry of the Eastern Regions of the USSR

- Ministry of the Coal Industry of the Western Regions of the USSR

- USSR Ministry of Chemical and Petroleum Engineering

- USSR Ministry of Chemical Industry

- Ministry of Pulp and Paper Industry of the USSR

- USSR Ministry of Electrotechnical Industry (Minelectrotechprom)

- USSR Ministry of Power Plants

- Ministry of Power Engineering

In the aftermath of the collapse of the USSR, many state enterprises were privatized into private ownership, the ministries were dissolved.

- July 14, 1990 formed Ministry of Industry of the RSFSR(Law of the RSFSR of July 14, 1990 No. 101-I).

- May 16, 1992 renamed to