Preview:

To use the preview of presentations, create a Google account (account) and sign in: https://accounts.google.com

Slides captions:

Presentation Natural and associated petroleum gases

Natural gases are mixtures of gaseous hydrocarbons of various structures that fill the pores and voids of rocks dispersed in soils, dissolved in oil and formation waters.

Natural gas

Natural gas is dominated by methane, the content of which reaches 80-98% Associated petroleum gases contain 30-50% methane, but much more than the closest homologues - ethane, propane and butane (up to 20% of each

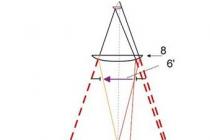

Compound natural gas

The main deposits of natural gases are located in the Northern and Western Siberia, the Volga-Ural basin, in the North. "Caucasus (Stavropol), in the Komi Republic.

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin. In the North Caucasus, in the Komi Republic, the Astrakhan region, the Barents Sea

Associated petroleum gases are mixtures of hydrocarbons associated with oil and released during its production from gas and oil fields. These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases Name composition Application Gasoline Mixture of pentane, hexane and other hydrocarbons Added to gasoline to improve engine start Propane-butane fraction Mixture of propane and butane Used in the form liquefied gas as fuel Dry gas Similar in composition to natural gas Used to produce acetylene, hydrogen and other substances, as well as fuel

APPLICATION About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, there is an ethane pipeline Orenburg - Kazan, in Kazan ethylene is obtained from ethane for organic synthesis.

Natural gas Use Fuel in boiler houses, furnaces, thermal power plants, in everyday life; Raw material in chem. industry

EFFICIENT AND CHEAP FUEL SOURCE OF RAW MATERIALS FOR THE CHEMICAL INDUSTRY Natural gas application

On the topic: methodological developments, presentations and notes

PRESENTATION CROSSWORD "PRESSURE IN LIQUIDS AND GASES"

Crossword "Pressure in liquids and gases." Compiled by V.A. Rybitskaya, MBOU "Lyceum No. 124".

This presentation helps the teacher to clearly and interestingly explain this topic. Unfortunately, the films "Secrets of Natural Gas" (accessible and interesting in the form of a cartoon provide informative information ...

Before the Great Patriotic War, industrial stocks natural gas were known in the Carpathian region, in the Caucasus, in the Volga region and in the North (Komi ASSR). The study of natural gas reserves was associated only with oil exploration. Industrial reserves of natural gas in 1940 amounted to 15 billion m 3 . Then gas fields were discovered in the North Caucasus, Transcaucasia, Ukraine, the Volga region, Central Asia, Western Siberia and the Far East. As of January 1, 1976, explored reserves of natural gas amounted to 25.8 trillion m3, of which 4.2 trillion m3 (16.3%) in the European part of the USSR, 21.6 trillion m3 (83. 7%), including 18.2 trillion m 3 (70.5%) - in Siberia and the Far East, 3.4 trillion m 3 (13.2%) - in Central Asia and Kazakhstan. As of January 1, 1980, potential reserves of natural gas amounted to 80–85 trillion m 3 , explored - 34.3 trillion m 3 . Moreover, the reserves increased mainly due to the discovery of deposits in the eastern part of the country - explored reserves there were at a level of about

30.1 trillion m 3, which was 87.8% of the all-Union.

Today, Russia has 35% of the world's natural gas reserves, which is more than 48 trillion m 3 . The main areas of occurrence of natural gas in Russia and the CIS countries (fields):

West Siberian oil and gas province:

Urengoyskoye, Yamburgskoye, Zapolyarnoye, Medvezhye, Nadymskoye, Tazovskoye – Yamalo-Nenets Autonomous Okrug;

Pokhromskoye, Igrimskoye - Berezovskaya gas-bearing region;

Meldzhinskoye, Luginetskoye, Ust-Silginskoye - Vasyugan gas-bearing region.

Volga-Ural oil and gas province:

the most significant is Vuktylskoye, in the Timan-Pechora oil and gas region.

Central Asia and Kazakhstan:

the most significant in Central Asia is Gazli, in the Ferghana Valley;

Kyzylkum, Bairam-Ali, Darvaza, Achak, Shatlyk.

North Caucasus and Transcaucasia:

Karadag, Duvanny - Azerbaijan;

Dagestan Lights - Dagestan;

Severo-Stavropolskoye, Pelagiadinskoye - Stavropol Territory;

Leningradskoye, Maykopskoye, Staro-Minskoye, Berezanskoye - Krasnodar Territory.

Also, natural gas deposits are known in Ukraine, Sakhalin and the Far East. In terms of natural gas reserves, Western Siberia stands out (Urengoyskoye, Yamburgskoye, Zapolyarnoye, Medvezhye). Industrial reserves here reach 14 trillion m 3 . The Yamal gas condensate fields (Bovanenkovskoye, Kruzenshternskoye, Kharasaveyskoye, etc.) are now acquiring particular importance. On their basis, the Yamal-Europe project is being implemented. Natural gas production is highly concentrated and focused on areas with the largest and most profitable deposits. Only five deposits - Urengoyskoye, Yamburgskoye, Zapolyarnoye, Medvezhye and Orenburgskoye - contain 1/2 of all industrial reserves of Russia. The reserves of Medvezhye are estimated at 1.5 trillion m 3 , and those of Urengoy – at 5 trillion m 3 . The next feature is the dynamic location of natural gas production sites, which is explained by the rapid expansion of the boundaries of the identified resources, as well as the relative ease and cheapness of their involvement in development. In a short time, the main centers for the extraction of natural gas moved from the Volga region to Ukraine, the North Caucasus. Further territorial shifts were caused by the development of deposits in Western Siberia, Central Asia, the Urals and the North.

After the collapse of the USSR in Russia, there was a drop in the volume of natural gas production. The decline was observed mainly in the Northern economic region (8 billion m 3 in 1990 and 4 billion m 3 in 1994), in the Urals (43 billion m 3 and 35 billion m And

555 billion m 3) and in the North Caucasus (6 and 4 billion m 3). Natural gas production remained at the same level in the Volga region (6 bcm) and in the Far East economic regions. At the end of 1994, there was an upward trend in production levels. Of the republics of the former USSR, the Russian Federation provides the most gas, in second place is Turkmenistan (more than 1/10), followed by Uzbekistan and Ukraine. Of particular importance is the extraction of natural gas on the shelf of the World Ocean. In 1987, offshore fields produced 12.2 billion m 3 , or about 2% of the gas produced in the country. Associated gas production in the same year amounted to 41.9 bcm. For many areas, one of the reserves of gaseous fuel is the gasification of coal and shale. Underground gasification of coal is carried out in the Donbass (Lysichansk), Kuzbass (Kiselevsk) and the Moscow Basin (Tula).

Natural gas was and remains an important export product in Russian foreign trade. The main natural gas processing centers are located in the Urals (Orenburg, Shkapovo, Almetyevsk), in Western Siberia (Nizhnevartovsk, Surgut), in the Volga region (Saratov), in the North Caucasus (Grozny) and in other gas-bearing provinces.

It can be noted that gas processing plants tend to sources of raw materials - deposits and large gas pipelines. The most important use of natural gas is as a fuel. Lately there is a tendency to increase the share of natural gas in the fuel balance of the country. As a gaseous fuel, natural gas has great advantages not only over solid and liquid fuels, but also over other types of gaseous fuels (blast furnace, coke oven gas), since its calorific value is much higher. Methane is the main component of this gas. In addition to methane, natural gas contains its closest homologues - ethane, propane, butane. The higher the molecular weight of the hydrocarbon, the less it is usually contained in natural gas.

Compound natural gas of different fields is different.

Average composition of natural gas:

|

N 2 and other gases |

||||||

|

Natural gas (% by volume) |

The most valued natural gas with a high content of methane is Stavropol (97.8% CH 4), Saratov (93.4%), Urengoy (95.16%).

Natural gas reserves on our planet are very large (approximately 1015 m 3). More than 200 deposits are known in Russia, they are located in Western Siberia, in the Volga-Ural basin, in the North Caucasus. Russia holds the first place in the world in terms of natural gas reserves.

Natural gas is the most valuable type of fuel. When gas is burned, a lot of heat is released, so it serves as an energy-efficient and cheap fuel in boiler plants, blast furnaces, open-hearth furnaces and glass melting furnaces. The use of natural gas in production makes it possible to significantly increase labor productivity.

Natural gas is a source of raw materials for the chemical industry: the production of acetylene, ethylene, hydrogen, soot, various plastics, acetic acid, dyes, medicines and other products.

Associated petroleum gas - this is a gas that exists together with oil, it is dissolved in oil and is located above it, forming a "gas cap", under pressure. At the exit from the well, the pressure drops, and the associated gas is separated from the oil.

Compound associated petroleum gas of different fields is different.

Average gas composition:

|

N 2 and other gases |

||||||

|

Passing petroleum gas (% by volume) |

Associated petroleum gas is also natural in origin. It received a special name because it is located in deposits along with oil:

Or dissolved in it,

Or is free

Associated petroleum gas also mainly consists of methane, but it also contains a significant amount of other hydrocarbons.

This gas was not used in the past, but was simply burned. It is currently being captured and used as a fuel and valuable chemical feedstock. The possibilities of using associated gases are even wider than those of natural gas. their composition is richer. Associated gases contain less methane than natural gas, but they contain significantly more methane homologues. In order to use associated gas more rationally, it is divided into mixtures of a narrower composition. After separation, gas gasoline, propane and butane, dry gas are obtained.

|

hydrocarbons |

C 3 H 8 , C 4 H 10 |

C 5 H 12 , C 6 H 14 etc. |

|

|

Released mixtures |

dry gas |

propane-butane mixture |

Gasoline |

|

Application |

Dry gas, similar in composition to natural gas, is used to produce acetylene, hydrogen and other substances, as well as as fuel. |

Propane and butane in a liquefied state are widely used as a fuel in everyday life and in road transport. |

Gasoline containing volatile liquid hydrocarbons is used as an additive to gasolines to improve their ignition when starting the engine. |

Individual hydrocarbons are also extracted - ethane, propane, butane and others. By dehydrogenating them, unsaturated hydrocarbons are obtained - ethylene, propylene, butylene, etc.

Associated petroleum gas (APG), as the name implies, is a by-product of oil production. Oil lies in the ground along with gas, and it is technically practically impossible to ensure the production of an exclusively liquid phase of hydrocarbon raw materials, leaving the gas inside the reservoir.

On this stage it is gas that is perceived as an associated raw material, since world oil prices determine the greater value of the liquid phase. Unlike gas fields, where all production and specifications production is aimed at extracting exclusively the gaseous phase (with an insignificant admixture of gas condensate), oil fields are not equipped in such a way as to effectively conduct the process of production and utilization of associated gas.

Further in this chapter, the technical and economic aspects of APG production will be considered in more detail, and based on the conclusions obtained, parameters will be selected for which an econometric model will be built.

General characteristics of associated petroleum gas

Description of the technical aspects of hydrocarbon production begins with a description of the conditions of their occurrence.

Oil itself is formed from the organic remains of dead organisms that settle on the sea and river bottom. Over time, water and silt protected the substance from decomposition, and as new layers accumulated, pressure on the underlying layers increased, which, together with temperature and chemical conditions, caused the formation of oil and natural gas.

Oil and gas go together. Under conditions of high pressure, these substances accumulate in the pores of the so-called parent rocks, and gradually, undergoing a process of continuous transformation, rise up with microcapillary forces. But as you go up, a trap can form - when a denser reservoir covers the reservoir along which hydrocarbon migrates, and thus accumulation occurs. At the moment when a sufficient amount of hydrocarbons has accumulated, the process of displacement of initially salty water, heavier than oil, begins to take place. Further, the oil itself is separated from the lighter gas, but some of the dissolved gas remains in liquid fraction. It is the separated water and gas that serve as tools for pushing oil outward, forming water or gas pressure regimes.

Based on the conditions, the depth of occurrence and the contour of the area of occurrence, the developer selects the number of wells to maximize production.

The main modern type of drilling used is rotary drilling. In this case, drilling is accompanied by a continuous rise of drill cuttings - fragments of the formation, separated by a drill bit, to the outside. At the same time, to improve drilling conditions, a drilling fluid is used, often consisting of a mixture chemical reagents. [Gray Forest, 2001]

The composition of associated petroleum gas will vary from field to field, depending on the entire geological history of the formation of these deposits (source rock, physical and chemical conditions, etc.). On average, the proportion of methane content in such a gas is 70% (for comparison, natural gas contains up to 99% of methane in its composition). A large amount of impurities creates, on the one hand, difficulties for gas transportation through the gas transmission system (GTS), on the other hand, the presence of such extremely important components as ethane, propane, butane, isobutane, etc. makes associated gas an extremely desirable raw material for petrochemical production. The oil fields of Western Siberia are characterized by the following indicators of hydrocarbon content in associated gas [Popular petrochemistry, 2011]:

- Methane 60-70%

- Ethane 5-13%

- Propane 10-17%

- Butane 8-9%

TU 0271-016-00148300-2005 "Associated petroleum gas to be delivered to consumers" defines the following categories of APG (according to the content of C 3 ++ components, g/m 3):

- "Skinny" - less than 100

- "Medium" - 101-200

- "Bold" - 201-350

- Extra fat - more than 351

The following figure [Filippov, 2011] shows the main activities carried out with associated petroleum gas and the effects achieved by these activities.

Figure 1 - The main activities carried out with APG and their effects, source: http://www.avfinfo.ru/page/engineering-002

During oil production and further stepwise separation, the released gas has a different composition - the very first gas is released with a high content of methane fraction, at the next stages of separation, gas is released with an increasing content of hydrocarbons of a higher order. The factors influencing the release of associated gas are temperature and pressure.

A gas chromatograph is used to determine the associated gas content. When determining the composition of associated gas, it is also important to pay attention to the presence of non-hydrocarbon components - for example, the presence of hydrogen sulfide in the APG composition can adversely affect the possibility of gas transportation, since corrosion processes can occur in the pipeline.

Figure 2 - Scheme of oil treatment and APG accounting, source: Skolkovo Energy Center

Figure 2 schematically depicts the process of stage-by-stage refinement of oil with the release of associated gas. As can be seen from the figure, associated gas is, for the most part, a by-product of the primary separation of hydrocarbons produced from an oil well. The problem of associated gas metering is the need to install automatic metering devices at several stages of separation, and later on deliveries for utilization (GPP, boiler houses, etc.).

The main installations used at production sites [Filippov, 2009]:

- Booster pumping stations(DNS)

- Oil separation units (USN)

- Oil treatment plants (UPN)

- Central oil treatment facilities (CPP)

The number of steps depends on physical and chemical properties associated gas, in particular, on such factors as gas content and gas factor. Often the gas from the first separation stage is used in furnaces to generate heat and preheat the entire mass of oil in order to increase the gas yield in the subsequent separation stages. For driving mechanisms, electricity is used, which is also generated in the field, or main power networks are used. Gas-piston power plants (GPES), gas turbine (GTS) and diesel generators (DGU) are mainly used. Gas facilities operate on gas of the first stage of separation, diesel station operates on imported liquid fuel. The specific type of power generation is selected based on the needs and characteristics of each individual project. The gas turbine power plant can in some cases generate excess electricity for neighboring oil production facilities, and in some cases the leftovers can be sold for wholesale market electricity. With the cogeneration type of energy production, the installations simultaneously produce heat and electricity.

Flare lines are a mandatory attribute of any field. Even if they are not used, they are necessary to burn excess gas in an emergency.

From the point of view of the economics of oil production, investment processes in the field of associated gas utilization are quite inertial, and are primarily oriented not to market conditions in short term, but on the totality of all economic and institutional factors on a sufficiently long-term horizon.

The economic aspects of hydrocarbon production have their own specifics. The peculiarity of oil production is:

- Long-term nature of key investment decisions

- Significant investment lags

- Large initial investment

- Irreversibility of the initial investment

- Natural decline in production over time

In order to evaluate the effectiveness of any project, a common business valuation model is the NPV estimate.

NPV (Net Present Value) - the assessment is based on the fact that all future estimated income of the company will be summed up and reduced to the present value of these incomes. The same amount of money today and tomorrow differs by the discount rate (i). This is due to the fact that in the period of time t=0 the money we have has a certain value. While in the time period t=1 on the data cash inflation will be widespread, there will be all sorts of risks and negative impacts. All this makes future money “cheaper” than current money.

The average life of an oil production project can be about 30 years, followed by a long shutdown of production, sometimes stretching for decades, which is associated with the level of oil prices and the payback of operating costs. Moreover, oil production reaches its peak in the first five years of production, and then, due to the natural decline in production, it gradually fades.

In the early years, the company makes large initial investments. But mining itself begins only a few years after the start. capital investments. Each company seeks to minimize the investment lag in order to reach the payback of the project as soon as possible.

A typical project profitability schedule is provided in Figure 3:

Figure 3 - NPV scheme for a typical oil production project

This figure shows the NPV of the project. The maximum negative value is the MCO indicator (maximum cash outlay), which is a reflection of how large investments the project requires. The intersection of the graph of the line of accumulated cash flows with the time axis in years is the payback time point of the project. The NPV accumulation rate is declining due to both the declining production rate and the time discount rate.

In addition to capital investments, annual production requires operating costs. An increase in operating costs, which may be annual technical costs, Related environmental risks, reduce the NPV of the project and increase the payback period of the project.

Thus, additional costs for accounting, collection and disposal of associated petroleum gas can be justified from the point of view of the project only if these costs will increase the NPV of the project. Otherwise, there will be a decrease in the attractiveness of the project and, as a result, either a decrease in the number of projects being implemented, or the volumes of oil and gas production within one project will be adjusted.

Conventionally, all associated gas utilization projects can be divided into three groups:

- 1. The recycling project itself is profitable (taking into account all economic and institutional factors), and companies will not need additional incentives to implement.

- 2. The disposal project has a negative NPV, while the cumulative NPV from the entire oil production project is positive. It is on this group that all incentive measures can be concentrated. General principle will be to create conditions (with benefits and penalties) under which it will be profitable for the company to carry out recycling projects, and not pay fines. And so that the total costs of the project do not exceed the total NPV.

- 3. Disposal projects have a negative NPV, and if they are implemented, common project oil production of this field also becomes unprofitable. In this case, incentive measures will either not lead to a reduction in emissions (the company will pay fines up to their cumulative cost equal to the NPV of the project), or the field will be mothballed and the license will be surrendered.

According to the Skolkovo Energy Center, the investment cycle in the implementation of APG utilization projects is more than 3 years.

Investments, according to the Ministry of Natural Resources, should amount to about 300 billion rubles by 2014 to achieve the target level. Based on the logic of the administration of projects of the second type, the rates of payments for pollution should be such that the potential cost of all payments would be more than 300 billion rubles, and the opportunity cost would be equal to the total investment.

Natural gas comes in many varieties. So, it can be presented in standard form or be classified as passing. What are its characteristics in both cases?

What are the features of associated gas?

Under passing natural gas refers to a substance that is a mixture of a wide range of hydrocarbons that are initially dissolved in oil. They are obtained by distillation of the corresponding raw materials. Associated gas is mainly represented by propane, as well as butane isomers. Sometimes methane, ethylene can become a product of oil distillation. Associated gas is actively used in chemical industry. It is a demanded raw material in the production of plastic, rubber products. Propane is among the most common gases used as automotive fuel.

What is the specificity of conventional natural gas?

Under natural gas In the usual form, a mineral is understood that is extracted from gas-bearing strata in a finished form, which, as a rule, does not require deep processing. In some cases, the type of gas under consideration may be in a crystalline state - in the form of gas hydrates. Sometimes it is dissolved in oil or in water.

Ordinary natural gas is represented most often by methane, sometimes by ethane, propane, butane. In some cases, it contains hydrogen, nitrogen, helium.

Comparison

The main difference between associated gas and natural gas is that the first is a product of oil refining, the second is extracted from the bowels of the earth in finished form. They also differ in the scope of use, to a large extent - in chemical composition.

Natural gas in its usual form is most often used as a fuel for heating residential and industrial premises, for ensuring the operation of power plants, production capacity at the factories. But it is worth noting that associated gas (if the company producing it manages to develop a sufficiently cheap technology for its production) can also be used as a fuel for heating large premises and ensuring the operation of industrial equipment. In turn, ordinary natural gas is also used as a feedstock in the chemical industry - for example, in the production of acetylene.

To display in more detail what is the difference between associated and natural gas, a small table will help us.

Unlike natural gas, associated petroleum gas contains, in addition to methane and ethane, a large proportion of propanes, butanes and vapors of heavier hydrocarbons. Many associated gases, depending on the field, also contain non-hydrocarbon components: hydrogen sulfide and mercaptans, carbon dioxide, nitrogen, helium and argon.

When opening oil reservoirs, the gas of oil "caps" usually begins to flow first. Subsequently, the main part of the produced associated gas is gases dissolved in oil. The gas of gas "caps", or free gas, is "lighter" in composition (with a lower content of heavy hydrocarbon gases) in contrast to the gas dissolved in oil. Thus, the initial stages of field development are usually characterized by large annual production of associated petroleum gas with a larger proportion of methane in its composition. With long-term operation of the field, the debit of associated petroleum gas is reduced, and a large proportion of gas is accounted for by heavy components.

Injection into the subsoil to increase reservoir pressure and, thereby, the efficiency of oil production. However, in Russia, unlike a number of foreign countries, this method, with rare exceptions, is not used, because it is a highly costly process.

Use in the field to generate electricity for the needs of the oil fields.

With the release of significant and stable volumes of associated petroleum gas - use as fuel at large power plants, or for further processing.

Most effective method utilization of associated petroleum gas - its processing at gas processing plants with the production of dry stripped gas (DOG), wide fraction of light hydrocarbons (NGL), liquefied gases (LHG) and stable gas gasoline (SGB).

Large consulting company in the fuel and energy sector, PFC Energy noted in its study "Associated Petroleum Gas Utilization in Russia" that the optimal use of APG depends on the size of the field. Thus, for small deposits, the most attractive option is to generate electricity on a small scale for their own field needs and the needs of other local consumers.

For medium-sized fields, the researchers estimate that the most cost-effective APG disposal option is to recover the LPG at a gas processing plant and sell the LPG or petrochemicals and dry gas.

For large deposits the most attractive option is to generate electricity at a large power plant for subsequent wholesale into the power system.

According to experts, solving the problem of associated gas utilization is not only a matter of ecology and resource saving, it is also a potential national project worth 10-15 billion dollars. Only the utilization of APG volumes would make it possible to annually produce up to 5-6 million tons of liquid hydrocarbons, 3-4 billion cubic meters of ethane, 15-20 billion cubic meters of dry gas or 60-70 thousand GW/h of electricity.

Russian President Dmitry Medvedev instructed the Russian government to take measures to stop the practice of wasteful use of associated gas by February 1, 2010.

For a long time, associated petroleum gas had no value. It was considered a harmful impurity in oil production and was burned directly when gas was released from an oil well. But time passed. New technologies have appeared that have made it possible to take a different look at APG and its properties.

Compound

Associated petroleum gas is located in the "cap" of the oil reservoir - the space between the soil and deposits of fossil oil. Also, some of it is in a dissolved state in the oil itself. In fact, APG is the same natural gas, the composition of which has a large amount of impurities.

Associated petroleum gas is characterized by a wide variety of hydrocarbon content. Mainly it is ethane, propane, methane, butane. It also contains heavier hydrocarbons: pentane and hexane. In addition, petroleum gas includes a certain amount of non-combustible components: helium, hydrogen sulfide, carbon dioxide, nitrogen and argon.

It should be noted that the composition of associated petroleum gas is extremely unstable. The same APG field is capable of significantly changing the percentage of certain elements over several years. This is especially true for methane and ethane. Even so, petroleum gas is highly energy intensive. One cubic meter of APG, depending on the type of hydrocarbons it contains, is capable of releasing from 9,000 to 15,000 kcal of energy, which makes it promising for use in various sectors of the economy.

In terms of associated petroleum gas production, Iran, Iraq, Saudi Arabia, the Russian Federation and other countries in which the main oil reserves are concentrated. Russia here accounts for about 50 billion cubic meters of associated petroleum gas per year. Half of this volume goes to the needs of production areas, 25% for additional processing, and the rest is burned.

cleaning

Associated petroleum gas is not used in its original form. Its use becomes possible only after preliminary cleaning. To do this, layers of hydrocarbons having different densities are separated from each other in equipment specially designed for this purpose - a multi-stage pressure separator.

Everyone knows that water in the mountains boils at a lower temperature. Depending on the height, its boiling point can drop to 95 ºС. This is due to the difference in atmospheric pressure. This principle is used in the operation of multistage separators.

Initially, the separator supplies a pressure of 30 atmospheres and after a certain period of time gradually reduces its value in increments of 2-4 atmospheres. This ensures uniform separation of hydrocarbons from different temperature boiling apart. Further, the obtained components are sent directly to the next stage of purification at oil refineries.

Use of associated petroleum gas

Now actively in demand in some areas of production. First of all, it is the chemical industry. For her, APG serves as a material for the manufacture of plastics and rubber.

The energy industry is also partial to the by-product of oil production. APG is a raw material from which the following types of fuel are obtained:

- Dry stripped gas.

- Broad fraction of light hydrocarbons.

- Gas motor fuel.

- Liquefied petroleum gas.

- Stable natural gasoline.

- Separate fractions based on carbon and hydrogen: ethane, propane, butane and other gases.

The volumes of associated petroleum gas use would be even higher if it were not for a number of difficulties that arise during its transportation:

- The need to remove mechanical impurities from the gas composition. During the expiration of APG from the well, the smallest soil particles get into the gas, which significantly reduce its transport properties.

- Associated petroleum gas must necessarily undergo a benzinization procedure. Without this, the liquefied fraction will precipitate in the gas pipeline during its transportation.

- The composition of associated petroleum gas must be desulphurised. The increased sulfur content is one of the main reasons for the formation of corrosion centers in the pipeline.

- Removal of nitrogen and carbon dioxide to increase calorific value gas.

Due to the above reasons, associated petroleum gas was not disposed of for a long time, but was burned directly near the well where the oil was deposited. It was especially good to observe this when flying over Siberia, where torches were constantly visible with black clouds of smoke leaving them. This continued until environmentalists intervened, realizing all the irreparable harm that is caused in this way to nature.

Consequences of incineration

The combustion of gas is accompanied by an active thermal effect on environment. Within a radius of 50-100 meters from the immediate place of burning, a noticeable decrease in the volume of vegetation is observed, and at a distance of up to 10 meters, there is a complete absence of it. This is mainly due to the burning out of the nutrient elements of the soil, on which all kinds of trees and grasses depend so much.

A burning torch serves as a source of carbon monoxide, the same one that is responsible for the destruction of the Earth's ozone layer. In addition, the gas contains sulfur dioxide and nitric oxide. These elements belong to the group of toxic substances for living organisms.

Thus, people living in areas with active oil production have an increased risk of developing various kinds of pathologies: oncology, infertility, weakened immunity, etc.

For this reason, at the end of the 2000s, the issue of APG utilization arose, which we will consider below.

Associated petroleum gas utilization methods

On this moment there are many options for the disposal of waste oil without harming the environment. The most common of these are:

- Sending directly to the oil refinery. It is the most optimal solution, both from a financial and environmental point of view. But on the condition that there is already a developed infrastructure of gas pipelines. In its absence, a significant investment of capital will be required, which is justified only in the case of large deposits.

- Utilization by using APG as fuel. Associated petroleum gas is supplied to power plants, where gas turbines produced from it electrical energy. The disadvantage of this method is the need to install equipment for pre-cleaning, as well as its transportation to the destination.

- Injection of spent APG into the underlying oil reservoir, thereby increasing the oil recovery factor of the well. This happens due to the increase under the soil layer. This option It is characterized by ease of implementation and relatively low cost of the equipment used. There is only one minus here - the lack of actual APG utilization. There is only a delay, but the problem remains unresolved.

Presentation Natural and associated petroleum gases

natural gases mixtures of gaseous hydrocarbons of various structures, filling the pores and voids of rocks dispersed in soils, dissolved in oil and formation waters.

Natural gas

Natural gas

Natural gas

prevails

methane, the content of which reaches 80-98%

Composition of natural gas

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin, in the North Caucasus (Stavropol), in the Komi Republic.

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin. In the North Caucasus, in the Komi Republic, the Astrakhan region, the Barents Sea

Associated petroleum gases mixtures of hydrocarbons associated with oil and released during its production from gas and oil fields. These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases

Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

Presentation Natural and associated petroleum gases

natural gases mixtures of gaseous hydrocarbons of various structures, filling the pores and voids of rocks dispersed in soils, dissolved in oil and formation waters.

Natural gas

Natural gas

Natural gas

prevails

methane, the content of which reaches 80-98%

Composition of natural gas

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin, in the North Caucasus (Stavropol), in the Komi Republic.

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin. In the North Caucasus, in the Komi Republic, the Astrakhan region, the Barents Sea

Associated petroleum gases mixtures of hydrocarbons associated with oil and released during its production from gas and oil fields. These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases

Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

natural gases mixtures of gaseous hydrocarbons of various structures, filling the pores and voids of rocks dispersed in soils, dissolved in oil and formation waters.

Natural gas

Natural gas

Natural gas

prevails

methane, the content of which reaches 80-98%

Composition of natural gas

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin, in the North Caucasus (Stavropol), in the Komi Republic.

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin. In the North Caucasus, in the Komi Republic, the Astrakhan region, the Barents Sea

Associated petroleum gases mixtures of hydrocarbons associated with oil and released during its production from gas and oil fields. These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases

Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

mixtures of gaseous hydrocarbons of various structures, filling the pores and voids of rocks dispersed in soils, dissolved in oil and formation waters.

Natural gas

Natural gas

Natural gas

prevails

methane, the content of which reaches 80-98%

Composition of natural gas

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin, in the North Caucasus (Stavropol), in the Komi Republic.

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin. In the North Caucasus, in the Komi Republic, the Astrakhan region, the Barents Sea

Associated petroleum gases mixtures of hydrocarbons associated with oil and released during its production from gas and oil fields. These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases

Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

Natural gas

Natural gas

Natural gas

prevails

methane, the content of which reaches 80-98%

Composition of natural gas

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin, in the North Caucasus (Stavropol), in the Komi Republic.

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin. In the North Caucasus, in the Komi Republic, the Astrakhan region, the Barents Sea

Associated petroleum gases mixtures of hydrocarbons associated with oil and released during its production from gas and oil fields. These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases

Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

Natural gas

prevails methane, the content of which reaches 80-98%

The main deposits of natural gases are located in Northern and Western Siberia, the Volga-Ural basin. In the North Caucasus, in the Komi Republic, the Astrakhan region, the Barents Sea

Associated petroleum gases mixtures of hydrocarbons associated with oil and released during its production from gas and oil fields. These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases

Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

Associated petroleum gases mixtures of hydrocarbons associated with oil and released during its production from gas and oil fields. These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases

Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

These gases are dissolved in oil and are released from it as a result of a decrease in pressure as oil rises to the Earth's surface.

Natural and associated petroleum gases

Associated petroleum gases are more diverse in composition, so it is more profitable to use them as chemical raw materials.

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

Characteristics of associated petroleum gases

APPLICATION

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, the Orenburg-Kazan ethane pipeline operates; in Kazan, ethylene is obtained from ethane for organic synthesis.

Natural gas Usage

Natural gas Usage

Natural gas is dominated by methane, the content of which reaches 80-98% Associated petroleum gases contain 30-50% of methane, but more of the closest homologues - ethane, propane and butane (up to 20% of each) 30-50% of methane, but significantly more of the nearest homologues - ethane, propane and butane (up to 20% each)

Name composition application Gasoline Mixture of pentane, hexane and other hydrocarbons Added to gasoline to improve engine starting Propane - butane fraction Mixture of propane and butane Used as liquefied gas as a fuel Dry gas Similar in composition to natural gas Used to produce acetylene, hydrogen and others substances, as well as fuel

About 90% of natural gases are used as fuel and only 10% as chemical raw materials. Hydrogen, soot, acetylene are obtained from methane. If the gas contains at least 3% ethane, then it is used to produce ethylene. In Russia, there is an ethane pipeline Orenburg Kazan, in Kazan ethylene is obtained from ethane for organic synthesis.

slide 1

"Associated petroleum gas and environmental problems arising from its disposal".

slide 2

Objectives of the work: To get acquainted with associated petroleum gas as an important raw material for the petrochemical industry. Consider the composition of the gas, its main characteristics, problems associated with its disposal. To reveal the essence of environmental problems arising from the extraction, processing and disposal of associated petroleum gas.

slide 3

APG is the most valuable hydrocarbon raw material along with oil and natural gas.

slide 4

Characteristics of PNG.

Associated petroleum gas (APG) is a natural hydrocarbon gas dissolved in oil or located in the “caps” of oil and gas condensate fields. In contrast to the well-known natural gas, associated petroleum gas contains, in addition to methane and ethane, a large proportion of propanes, butanes and vapors of heavier hydrocarbons. Many associated gases, depending on the field, also contain non-hydrocarbon components: hydrogen sulfide and mercaptans, carbon dioxide, nitrogen, helium and argon.

slide 5

Associated petroleum gas is an important raw material for the energy and chemical industries.

slide 6

In Russia, according to official data, about 55 billion m3 of associated petroleum gas is extracted annually. Of these, about 20-25 billion m3 is burned in the fields and only about 15-20 billion m3 is used in the chemical industry. Most of the APG flared comes from new and hard-to-reach fields in Western and Eastern Siberia. An important indicator for everyone oil field is the GOR of oil - the amount of associated petroleum gas per ton of oil produced. For each field, this indicator is individual and depends on the nature of the field, the nature of its operation and the duration of development and can range from 1-2 m3 to several thousand m3 per ton.

Slide 7

The main problems associated with the use of APG in Russia.

In 2002, in total Russian Federation extracted from the bowels of 34.2 billion cubic meters. m of associated gas (APG), of which 28.2 billion cubic meters were consumed. m. Thus, the level of APG utilization amounted to 82.5%, while about 6 billion cubic meters burned in flares. m (17.5%).

Slide 8

The main directions of APG use.

1. Consumption of APG as fuel. 2. Consumption of APG as a feedstock for petrochemicals.

Slide 9

Associated petroleum gas flaring is a serious environmental problem both for the oil-producing regions themselves and for the global environment.

Slide 10

APG combustion products and their impact on the human body and the environment.

slide 11

Associated petroleum gas (APG) combustion products entering the environment are a potential threat to the normal functioning of the human body at the physiological level. Very dangerous impacts, the consequences of which are not immediately apparent. These are the impact of pollutants on the ability of people to conceive and bear children, the development of hereditary pathologies, the weakening of the immune system, and the increase in the number of oncological diseases.

slide 12

Production of associated petroleum gas in the Perelyubsky district of the Saratov region.

Oil production has been carried out on the territory of the Perelyubsky district for about 20 years. Currently, there are 8 large locations of hydrocarbon raw materials. The largest well is Razumovskaya, which has a separator for associated gas treatment. It is transported to the all-Russian gas pipeline system Yug, associated petroleum gas from some other wells is used to move oil to the Smorodinka station. Most wells flare gas. In 2002, about 305,123 thousand m3 were burned. The combustion of associated petroleum gas releases into the atmosphere a large number of toxic substances (Table 1). But the population of the region, and especially the territories where the torches are located, are not protected by anything. People should undergo preventive examination and fluorography annually.