The world around us is made up of complex shapes. Everything on earth was created by nature, and, having been polished for millions of years, the shape of objects acquired a finished version corresponding to their inner content. If we observe a tree, then we see it at the surface of the earth as a thick cylinder, the diameter of which decreases with height. Very thin branches scatter from the trunk in different directions. The tree is firmly fixed in the ground: the interweaving of roots creates a powerful foundation in the soil, and only a rare hurricane is able to topple a tree and, even more rarely, break its trunk. Nature has verified with time the dimensions that are necessary for strength.

Man creates new world- the world of things he needs. A very long time ago, when man first took up primitive tools, he created the future object first in his imagination. Gradually in creative activity between the imaginary and the finished object a drawing arose. This convenient form made it possible to repeat the inventions of one gifted person, to accelerate social progress.

IN modern world the answer to the question of how one or another product or structure should be made is given by a set of design and technological documentation. The main place in it is occupied by drawings. What is a drawing? It is an image of a machine, structure and technical device and their details, indicating the size, scale, composition. Without a drawing, it is impossible to manufacture them and control their quality. Designers consider drawing the language of technology. He tells (without words!) About the design, about the diverse relationships and forms of the future machine, its dimensions, processing of parts, etc.

Without a drawing it is impossible to understand and thus impossible to put into practice any of the most interesting idea whether it refers to building a house, a road, a street lamp, a woman's dress, a wardrobe, a television, or spaceship. It is in the drawing that the idea is fixed, and the designers can analyze the decisions made, put forward new ones, compare and evaluate them. Designers are working on their initial ideas, making numerous sketches and sketches. But there comes a time when the work of a designer requires professional cooperation with draftsmen.

Typically, a draftsman builds working drawings from a sketch made by a design engineer, provided with the overall dimensions of the parts. In these drawings, he expresses in graphical form, and partly in the form of textual material, the grade of the material, the accuracy of the processing of parts, depicts the details in the required number of projections. When performing this work, any draftsman is guided by a system of rules fixed in the "Unified System for Design Documentation". These rules ensure the unity of requirements for drawings and facilitate the work of draftsmen. However, they do not deprive the work of the draftsman of independence and creativity. The draftsman does not just redraw the sketch, but analyzes the features of the drawing, mentally singles out the most important relationships from the secondary ones, outlines a plan for his work.

Any drawing begins with a markup, during which the draftsman thinks and decides how to place the image on the drawing, on what format, what scale, and what projection to choose. It is not only (and not so much!) knowledge of purely technical methods that helps to make a competent decision, but the ability to understand the essence of a technical idea and the principles of construction.

After completing the drawings of all the details, an assembly drawing is made. This stage of work is the most responsible both in terms of design and drawing. The assembly drawing seems to model the structure as a whole: the correctness of the given dimensions is checked and the oversights made in the work on the details are revealed (any dimension lines are omitted, it is necessary to draw an additional section of a difficult place).

The draftsman-designer himself draws up a sketch and independently develops drawings for the implementation of a prototype product proposed by the worker-inventor. There is even more scope for expressing logical thinking (mental analysis of the features of the part) and spatial imagination (determining how the visible appearance of the part will change when it is transferred to the drawing plane).

Until recently, a special working device was a faithful assistant to the draftsman. Now he has at his disposal electronic pencils, displays, which are part of computer-aided design systems, including computers. The draftsman must be ready to work with microprocessor and computer technology.

The work of a draftsman requires steady attention, concentration, perseverance and physical endurance. During the work of the draftsman, the entire muscular system is in action. For example, in order to put a point in a specific place on a paper, it is necessary to clearly fix the position of the legs on the floor, orient the body and direct the movement of the hand with great accuracy. The muscles are tense, and they cannot relax: you just have to swing your leg, and the pencil will crawl to the side. Significant eye strain. With experience, this tension is somewhat reduced. An experienced draftsman is distinguished by fast movements, accurate in strength and direction, and high sensory-motor coordination.

A qualified draftsman never forgets that his drawing will lie in front of a turner or miller. If it is accurate, clean, then the worker will spend less time studying it and will quickly begin to manufacture the part. Finely crafted drawing, beautifully and clearly written letters and numbers create the worker's positive emotions, and he wants to do his job beautifully. A qualified draftsman is distinguished by composure, accuracy, diligence.

A draftsman needs to know a lot: methods of geometric, projection drawing, design basics, technology of metals, plastics or other materials, tolerances, fit, technical measurements etc. Of the subjects that are studied in high school, most of all he will need knowledge of mathematics, physics, drawing, the basics of computer science and computer technology.

Over time, the draftsman will have to turn to a pencil and ruler less and less, the draftsman will have less and less routine work, leaving time for creative reflection on his work. The draftsman is seen in the future as a draftsman - a computer operator. This is tomorrow's design day.

Thousands of workers in this profession are behind all the objects around us at home and at work, on the street and in the cinema. The man-made world seems to obey the inaudible movement of graphite across a clean field of white paper and then turns into booming trains or household trifles. This enduring profession began with rough lines in the sand and is now moving from paper sheets to display screens.

Draftsmen work in design bureaus in departments of various associations, enterprises, research institutions.

The profession of a draftsman can be obtained in secondary specialized educational institutions of the country.

The work of a qualified and loving draftsman often approaches the creative activity of a designer. Over time, the specifics of the enterprise where he works are known, there is a desire to create new products himself - you just need to deepen your knowledge. Some enterprises have their own educational institutions, where you can get higher education.

In all manufacturing plants, before manufacturing any the new kind products, are engaged in the design of the product and prepare the corresponding drawings. These works are carried out by well-trained specialists. The profession of a draftsman-designer is in great demand at all technical manufacturing enterprises. Such specialists are engaged in design and engineering work, maintain documentation and draw up drawings.

Many manufacturing enterprises provide services for the manufacture of non-standard products. In order to manufacture any non-standard product, you must first carry out all necessary calculations and prepare a specification with drawings, according to which specialists will produce the necessary parts. There is always a good demand on the labor market for specialists who prepare all the necessary documentation, so a draftsman-designer will never be left without work.

Responsibilities

A lot of design bureaus and manufacturing enterprises in our country are engaged in the manufacture of non-standard products and the development of various new devices and parts. The specialty of a draftsman-designer requires great responsibility, and qualified workers have the following responsibilities:

Knowledge

Specialist SPO 151901.01 "Drafter-Designer" must know:

- features of design work;

- organization of labor;

- technical drawing;

- ways of performing drawing and design work;

- rules of conduct general documentation;

- nomenclature of documents;

- internal order;

- parameters and features of the material used;

- quality standardization;

- labor protection standards.

Education

Russia has educational institutions, which are engaged in the preparation of draftsmen-designers, so school graduates who have completed grades 9 or 11 will not be difficult to choose a technical school or college where they will study. The terms of training depend on the form of attending classes and the available education.

The educational program in the specialty of SPO "Drafter-Designer" includes the study of such specialized subjects:

- design technology;

- technical mechanics;

- computer graphics;

- Materials Science;

- electrical engineering;

- drawing;

- engineering graphics;

- technical measurements;

- Informatics;

- mechanical engineering;

- metal processing technology;

- metalworking equipment;

- strength of materials;

- technical graphics;

- occupational Safety and Health.

After graduating from college, draftsmen-designers will be well aware of:

The training program provides for the passage industrial practice in existing design bureaus, where students can consolidate their theoretical knowledge.

Employment

Pick up a good place work for draftsmen-designers will not be difficult at all, since a large number of enterprises and organizations need qualified workers in this specialty. Therefore, graduates of specialized educational institutions will only have to choose from a large number interesting offers where and by whom they will work. The labor market is full of job offers for such specialists.

Skilled workers of this specialty develop new types of products and draw up related documentation for the manufacture of non-standard products. This job requires a lot of responsibility. The responsibilities of a draftsman include:

Professionals who make technical documentation and design development, should know well:

- rules for performing drawing work;

- basic principles proper organization labor;

- exploitation technological equipment;

- drawing tools and fixtures;

- software, which allows you to perform calculations and design models;

- specifications and quality standards;

- labor internal regulations;

- scaling rules;

- ways to create experimental models;

- labor protection.

In accordance with clause 5.2.41 of the Regulations on the Ministry of Education and Science Russian Federation, approved by Decree of the Government of the Russian Federation of June 3, 2013 N 466 (Collected Legislation of the Russian Federation, 2013, N 23, Art. 2923), I order:

II. Abbreviations Used

The following abbreviations are used in this standard:

SPO - average professional education;

GEF SPO - federal state educational standard of secondary vocational education;

PPKRS - training program for skilled workers, employees by profession;

OK - general competence;

PC - professional competence;

PM - professional module;

MDK is an interdisciplinary course.

III. Characteristics of training by profession

3.1. Terms of obtaining SPO by profession 151901.01 Draftsman-designer in full-time training and related qualifications are given in .

Table 1

_____________________________

* GEF SPO in terms of the requirements for the results of mastering the PPKRS is focused on assigning a graduate a qualification above the average qualification for this profession.

** Regardless of the applied educational technologies.

*** Educational organizations that train skilled workers serving on the basis of basic general education implement the federal state educational standard of secondary general education within the framework of the PPKRS, including taking into account the profession acquired by the SPO.

draftsman - draftsman-designer.

The terms for obtaining SPO for PPKRS, regardless of the educational technologies used, are increasing:

a) for full-time and part-time students:

on the basis of secondary general education - no more than 1 year;

on the basis of basic general education - no more than 1.5 years;

b) for the disabled and persons with disabilities - no more than 6 months.

IV. Characteristics of the professional activity of graduates

4.1. Region professional activity graduates: performance of design and engineering works, execution of technical drawings, sketches and maps based on measurements and other special data, copying of drawings and drawings, technical design in industry and construction.

4.2. The objects of professional activity of graduates are:

sketch documents;

tools and devices for drawing;

computer technology;

design documentation;

calculator.

4.3. A student by profession 151901.01 A draftsman-designer is preparing for the following activities:

4.3.1. Performing drawing work.

4.3.2. Conducting the process of drawing and simple calculation and design work.

V. Requirements for the results of the training program for skilled workers, employees

5.1. A graduate who has mastered the PPKRS must have general competencies including the ability to:

OK 1. Understand the essence and social significance future profession show a sustained interest in it.

OK 2. Organize their own activities, based on the goal and ways to achieve it, determined by the head.

OK 3. Analyze work situation, carry out current and final control, evaluation and correction of their own activities, be responsible for the results of their work.

OK 4. Search for information necessary for the effective performance of professional tasks.

OK 5. Use information and communication technologies in professional activities.

OK 6. Work in a team, communicate effectively with colleagues, management, clients.

OK 7. Perform military duty, including using the acquired professional knowledge (for boys).

5.2. A graduate who has mastered the PPKRS should have professional competencies corresponding to the types of activity:

5.2.1. Performing drawing work.

PC 1.1. Perform detail drawings, general view drawings, dimensional and installation drawings according to sketch documents or from nature.

PC 1.2. Prepare drawings.

PC 1.3. Compose and draw diagrams.

PC 1.4. Perform specifications, various statements and tables.

5.2.2. Conducting the process of drawing and simple calculation and design work.

PC 2.1. Draw assembly drawings and perform their detailing.

PC 2.2. Make sketches of parts simple designs.

PC 2.3. Perform simple technical calculations.

PC 2.4. Make changes adopted during the development process to the design documentation and draw up notices of changes.

VI. Requirements for the structure of the training program for skilled workers, employees

6.1. PPKRS provides for the study of the following training cycles:

general professional;

professional

and sections:

Physical Culture;

educational practice;

Internship;

intermediate certification;

state final certification.

6.2. The mandatory part of the PPCR should be about 80 percent of the total time allotted for its development. The variable part (about 20 percent) makes it possible to expand and (or) deepen the training, determined by the content of the mandatory part, to obtain additional competencies, skills and knowledge necessary to ensure the competitiveness of the graduate in accordance with requests regional market employment and opportunities for continuing education. Disciplines, interdisciplinary courses and professional modules of the variable part are determined by the educational organization.

The general professional training cycle consists of general professional disciplines, the professional training cycle consists of professional modules in accordance with the types of activities corresponding to the qualification(s) being awarded. The professional module includes one or more interdisciplinary courses. When students master professional modules, educational and (or) work practice is carried out.

The obligatory part of the professional training cycle of the PPKRS should include the study of the discipline "Life Safety". The volume of hours for the discipline "Life Safety" is 2 hours per week during the period of theoretical training (mandatory part of the training cycles), but not more than 68 hours, of which 70 percent of the total amount of time allotted for the specified discipline is for mastering the basics of military service.

6.3. An educational organization, when determining the structure of the PPKRS and the complexity of its development, can use a system of credits, while one credit corresponds to 36 academic hours.

The structure of the training program for skilled workers, employees

table 2

| Index | Name of training cycles, sections, modules, requirements for knowledge, skills, practical experience | Total maximum student workload (hour/week) | Incl. hours of compulsory training | Index and name of disciplines, interdisciplinary courses (MDC) | Codes of generated competencies |

|---|---|---|---|---|---|

| Mandatory part of the training cycles of the PPCR and the section " Physical Culture" | 756 | 504 | |||

| OP.00 | General professional training cycle | 282 | 188 | ||

| As a result of studying the compulsory part of the educational cycle, a student in general professional disciplines must: be able to: analyze technical documentation; determine the maximum deviations of dimensions according to standards, technical documentation; perform calculations of the maximum dimensions and tolerances according to the drawing and determine the suitability of the given dimensions; determine the nature of the pairing (landing group) according to the drawings, according to the calculations performed; to carry out schedules of tolerance fields according to the performed calculations; use control and measuring devices and tools; know: the system of tolerances and landings; quality and roughness parameters; basic principles of calibration of complex profiles; bases of interchangeability; methods for determining measurement errors; basic information about interfaces in mechanical engineering; tolerances for the main types of machining and for parts supplied for assembly; basic principles of calibration of simple and medium difficulty profiles; standards for materials, fasteners and normalized parts and assemblies; the name and properties of the completed materials; device, purpose, rules for setting up and regulating control and measuring instruments and devices; methods and means of control of treated surfaces. | OP.01. Technical measurements | ||||

| be able to: read and draw up drawings, diagrams and graphs; draw up sketches for workpieces with tolerances and fits; use reference literature; use the specification in the process of reading assembly drawings, diagrams; perform calculations of the maximum dimensions and tolerances according to the drawing data and determine the suitability of the given actual dimensions; know: the basics of drawing and geometry; requirements unified system design documentation (ESKD); rules for reading diagrams and drawings of machined parts; ways of making working drawings and sketches. | OP.02. technical graphics | ||||

| be able to: read structural, assembly and simple circuit diagrams; calculate and measure the main parameters of simple electrical, magnetic and electronic circuits; use electrical measuring instruments; start and stop the electric motors installed on the operated equipment; know: units of measurement of current, voltage, power of electric current, resistance of conductors; methods for calculating and measuring the main parameters of simple electrical, magnetic and electronic circuits; properties of direct and alternating electric current; principles of serial and parallel connection of conductors and current sources; electrical measuring instruments (ammeter, voltmeter), their device, principle of operation and rules for inclusion in an electrical circuit; properties of the magnetic field; motors of direct and alternating current, their device and principle of operation; rules for starting and stopping electric motors installed on equipment in operation; motor protection equipment; short circuit protection methods; grounding, grounding. | OP.03. Fundamentals of Electrical Engineering | ||||

| be able to: perform mechanical tests of samples of materials; use physico-chemical methods for the study of metals; use reference tables to determine the properties of materials; choose materials for the implementation of professional activities; know: the main properties and classification of materials used in professional activities; name, marking, properties of the processed material; rules for the use of coolants and lubricants; basic information about metals and alloys; basic information about non-metallic, gasket, sealing and electrical materials, steel, their classification. | OP.04. Fundamentals of materials science | ||||

| be able to: determine the cutting mode according to the manual and passport of the machine; draw up technical documentation; calculate cutting conditions using formulas, find reference books at different types processing; draw up a technological process for processing parts, products on machine tools; know: basic information about mechanisms, machines and machine parts; name, purpose and conditions for the use of the most common universal and special devices; device, kinematic diagrams and principle of operation, rules for adjusting metalworking machines of various types; rules Maintenance and methods for checking, accuracy standards for lathes, milling, boring and grinding machines; purpose and rules of application cutting tool; angles, rules for sharpening and installing cutters and drills; purpose and rules of use, rules for heat treatment of cutting tools made of tool steels, with hard alloy or ceramic plates, its main angles and rules for sharpening and installation; rules for determining cutting conditions according to reference books and machine data sheets; lifting equipment used in metalworking shops; the main directions of automation of production processes; basic concepts and definitions of technological processes for manufacturing parts and processing modes; fundamentals of the theory of cutting metals within the scope of the work performed; basing principle; general information about the design of technological processes; the procedure for issuing technical documentation; basic information about integrated mechanization, automation and production management; design rules working documentation in progress. | OP.05. General fundamentals of metalworking technology and work on metal-cutting machines | ||||

| be able to: organize and carry out activities to protect workers and the public from the negative effects of emergency situations; undertake preventive measures to reduce hazards different kind and their consequences in professional activity and everyday life; use means of individual and collective protection against weapons of mass destruction; use primary fire extinguishing means; navigate the list of military registration specialties and independently determine among them those related to the received profession; apply professional knowledge in the course of performing the duties of military service in military positions in accordance with the profession received; own ways of conflict-free communication and self-regulation in everyday activities and extreme conditions of military service; provide first aid to the injured; know: the principles of ensuring the sustainability of economic objects, forecasting the development of events and assessing the consequences in man-made emergencies and natural phenomena, including in the context of countering terrorism as a serious threat to Russia's national security; the main types of potential hazards and their consequences in professional activities and everyday life, the principles for reducing the likelihood of their implementation; fundamentals of military service and defense of the state; tasks and main activities of civil defense; ways to protect the population from weapons of mass destruction; fire safety measures and regulations safe behavior during fires; organization and procedure for conscription of citizens for military service and admission to it on a voluntary basis; main types of weapons military equipment and special equipment, which are in service (equipment) of military units, in which there are military registration specialties related to the professions of the SPO; the scope of the acquired professional knowledge in the performance of military service duties; the procedure and rules for providing first aid to victims. | 28 | OP.06. Life safety | |||

| P.00 | Professional study cycle | 474 | 316 | ||

| PM.00 | Professional modules | 474 | 316 | ||

| PM.01 | Conducting the process of drawing and simple calculation and design work As a result of studying the professional module, the student must: have practical experience: drawing assembly drawings and general view drawings; execution of detailing of assembly drawings; making sketches of parts and assembly drawings of simple structures from nature; performing simple technical calculations; making changes to the design documentation adopted during the development process; drafting notices of changes in design documentation; work with computer programs for preparation of design documentation; be able to: under the guidance of a more qualified specialist, carry out sketches and working drawings for the design of products; draw assembly drawings, general arrangement drawings, dimensional and installation drawings from sketches or from nature, as well as other design documentation; take sketches of simple designs of parts, products from nature; perform detailing of assembly drawings, simple technical calculations based on initial data in accordance with the developed programs and methods or standard calculations; draw up diagrams, specifications, various statements and tables; make changes to the design documentation adopted during the development process; draw up notices of changes; draw up drawings: carry out the minimum required number of images, affix symbols and dimensions, make the necessary inscriptions; know: the order and sequence of detailing assembly drawings; rules for applying tolerances, fits, surface roughness parameters, geometric deviations in the shape and location of surfaces on drawings during detailing; basics of design; methods and means of performing drawing and design work; nomenclature of design documents; methods and means of performing technical calculations; manufacturing technology and conditions technical operation products under development; technical conditions for the operation of the designed products; brands, properties, application of basic structural materials; manufacturing technology of the developed products; the principle of choice of materials and workpieces in the design of machine parts; types, purpose and procedure for calculating typical parts and structures; requirements for the organization of the workplace of a draftsman-designer; sketch requirements; sketching tool, measuring tool, measurement technique; sketching order; ESKD requirements for the order of changes in design documentation. | MDK.01.01. Technology for designing machine parts MDK.01.02. Computer graphics | |||

| PM.02 | Performing drawing work As a result of studying the professional module, the student must: have practical experience: making drawings of parts, dimensional and installation drawings according to sketches or from nature; preparation of drawings, the implementation of the necessary inscriptions and symbols; drawing up and drawing diagrams; drawing up specifications, various statements and tables; be able to: perform drawing work (drawings of parts, dimensional and installation drawings and other design documentation) according to sketches or from life in the required scale in ink or pencil in compliance with the drawing rules; draw up diagrams, specifications, various statements and tables; draw up drawings: carry out the minimum required number of images, affix symbols and dimensions, make the necessary inscriptions; know: the rules and techniques of geometric and projection drawing; basic techniques of computer graphics; fundamentals of technology in mechanical engineering; the concept of machines and mechanisms and their varieties; the concept of links and kinematic pairs; classification of machine parts for general and special purposes; structural elements of parts; methods and means of performing drawing work; basics of technical drawing; section and cuts and their design in the drawings; types of working drawings, requirements for them; rules for organizing the workplace of a draftsman; tools and devices used in drawing; standards, specifications and instructions for drawing up drawings; drawing rules; types, ratios and sizes of a standard drawing font; remote elements; designation of drawings of various stages of the project; classification of text documentation; rules for the compilation, design and designation of statements, tables, specifications; purpose and procedure for compiling statements of accompanying technical documentation; classification of schemes by purpose, by the method of their representation, by the type of elements of the scheme and their connections; symbols of elements and their connections in kinematic schemes; basic concepts of hydraulic elements and their symbols on the diagrams; basic concepts of pneumatic elements and their symbols on the diagrams; basic concepts of electrical and electronic elements and their symbols on the diagrams. | MDK.02.01. Mechanical engineering drawing | |||

| FC.00 | Physical culture As a result of mastering the section, the student must: be able to: use physical culture and health-improving activities to improve health, achieve life and professional goals; know: about the role of physical culture in the general cultural, professional and social development person; basics healthy lifestyle life. | 68 | 34 | ||

| Variable part of the PPKRS training cycles (determined by the educational organization) | 162 | 108 | |||

| Total for the mandatory part of the PPKRS, including the section "Physical culture", and the optional part of the PPKRS | 918 | 612 | |||

| UP.00 | Educational practice | 21 weeks | 756 | ||

| PP.00 | Internship | ||||

| PA.00 | Intermediate certification | 1 week | |||

| GIA.00 | State final certification | 2 weeks |

Table 3

The term for obtaining secondary vocational education in full-time PPKRS is 43 weeks, including:

VII. Requirements for the conditions for the implementation of the training program for skilled workers, employees

7.1. The educational organization independently develops and approves the PPKRS in accordance with the Federal State Educational Standards of the SPO, determining the profession or group of occupations of workers (positions of employees) according to OK 016-94 (based on the recommended list of their possible combinations according to the Federal State Educational Standards of the SPO), and taking into account the corresponding exemplary PPKRS.

Before starting the development of PPKRS, an educational organization must determine its specifics, taking into account the focus on meeting the needs of the labor market and employers, and specify the end results of training in the form of competencies, skills and knowledge, and practical experience gained.

The specific types of activities for which the student is preparing must correspond to the qualification(s) assigned, determine the content educational program developed by an educational organization together with interested employers.

When forming the PPKRS educational organization:

has the right to use the amount of time allotted for the variable part of the training cycles of the PPKRS, while increasing the amount of time allotted for the disciplines and modules of the mandatory part, or introducing new disciplines and modules in accordance with the needs of employers and the specifics of the activities of the educational organization;

is obliged to annually update the training program for skilled workers, employees, taking into account the requests of employers, the characteristics of the development of the region, science, culture, economics, engineering, technology and social sphere within the framework established by this federal state educational standard;

is obliged in the work programs of all disciplines and professional modules to clearly formulate the requirements for the results of their development: competencies, acquired practical experience, knowledge and skills;

must provide effective independent work students in combination with the improvement of its management by teachers and masters of industrial training;

is obliged to provide students with the opportunity to participate in the formation of an individual educational program;

is obliged to form a socio-cultural environment, create the conditions necessary for the comprehensive development and socialization of the individual, preserve the health of students, promote the development of the educational component of the educational process, including the development of self-government, the participation of students in work public organizations, sports and creative clubs;

should provide for the implementation of the competency-based approach, the use in the educational process of active forms of conducting classes using electronic educational resources, business and role-playing games, individual and group projects, analysis of production situations, psychological and other trainings, group discussions in combination with extracurricular work for the formation and development of general and professional competencies students.

7.2. When implementing PPKRS, students have academic rights and obligations in accordance with the Federal Law of December 29, 2012 N 273-FZ "On Education in the Russian Federation" .

7.3. The maximum volume of the student's study load is 54 academic hours per week, including all types of classroom and extracurricular (independent) academic work on the development of PPKRS and consultations.

7.4. The maximum amount of classroom teaching load in full-time education is 36 academic hours per week.

7.5. The maximum amount of classroom teaching load in part-time education is 16 academic hours per week.

7.6. Total duration vacation is at least 10 weeks per academic year with a study period of more than 1 year and at least 2 weeks in the winter period with a study period of 1 year.

7.7. In the discipline "Physical culture", 2 hours of independent study load can be provided weekly, including game types of training (due to various forms of extracurricular activities in sports clubs, sections).

7.8. An educational organization has the right for subgroups of girls to use 70 percent of the study time of the discipline "Life Safety", allotted for studying the basics of military service, for mastering the basics of medical knowledge.

7.9. Obtaining secondary vocational education on the basis of basic general education is carried out with the simultaneous receipt of secondary general education within the framework of the PPKRS. In this case, the PPKRS, implemented on the basis of basic general education, is developed on the basis of the requirements of the relevant federal state educational standards for secondary general and secondary vocational education, taking into account the received profession of secondary vocational education.

The term for mastering the PPKRS in full-time education for persons studying on the basis of basic general education is increased by 82 weeks at the rate of:

7.10. Consultations for students in full-time and part-time forms of education are provided by the educational organization at the rate of 4 hours per student for each academic year, including during the implementation of the educational program of secondary general education for persons studying on the basis of basic general education. Forms of consultations (group, individual, written, oral) are determined by the educational organization.

7.11. During the training period, training camps are held with young men.

7.12. Practice is a mandatory section of the PPCR. It is a type of educational activity aimed at the formation, consolidation, development of practical skills and competencies in the process of performing certain types of work related to future professional activities. When implementing the PPKRS, the following types of practices are envisaged: educational and industrial.

Educational practice and work practice are carried out by an educational organization when students master professional competencies within the framework of professional modules and can be implemented both concentratedly in several periods, and dispersed, alternating with theoretical classes within the framework of professional modules.

Goals and objectives, programs and reporting forms are determined by the educational organization for each type of practice.

Industrial practice should be carried out in organizations whose activities correspond to the profile of training students.

Certification based on the results of industrial practice is carried out taking into account (or on the basis of) the results confirmed by the documents of the relevant organizations.

7.13. The implementation of the training program for skilled workers, employees by profession should be provided by teaching staff with a secondary vocational or higher education corresponding to the profile of the discipline (module) being taught. Masters of industrial training should have 1-2 ranks in the profession of a worker higher than that provided for by the Federal State Educational Standards of secondary vocational education for graduates. Experience in relevant organizations professional sphere is mandatory for teachers responsible for the development of a professional training cycle by students, these teachers and masters of industrial training receive additional professional education under advanced training programs, including in the form of internships in specialized organizations at least 1 time in 3 years.

7.14. PPKRS should be provided with educational and methodological documentation for all disciplines, interdisciplinary courses and professional modules of PPKRS.

Extracurricular work should be accompanied by methodological support and justification for calculating the time spent on its implementation.

The implementation of the PPCRMS should be ensured by the access of each student to databases and library funds formed according to complete list disciplines (modules) PPKRS. During self-study Students must be provided with access to the Internet.

Each student must be provided with at least one educational printed and / or electronic publication for each discipline of the general professional educational cycle and one educational and methodical printed and / or electronic publication for each interdisciplinary course (including electronic bases periodicals).

The library stock should be completed with printed and/or electronic publications main and additional educational literature in the disciplines of all academic cycles published over the past 5 years.

The library fund, in addition to educational literature, should include official, reference and bibliographic and periodicals in the amount of 1-2 copies for every 100 students.

Each student should be provided with access to the library fund sets, consisting of at least 3 titles of domestic journals.

An educational organization should provide students with the opportunity to quickly exchange information with domestic organizations, including educational organizations, access to modern professional databases and information resources the Internet.

7.15. Admission to PPKRS training at the expense of budgetary appropriations federal budget, budgets of constituent entities of the Russian Federation and local budgets is public, unless otherwise provided by part 4 of article 68 federal law dated December 29, 2012 N 273-FZ "On Education in the Russian Federation" . Funding for the implementation of the PPCR should be carried out in an amount not lower than the established state standard costs for the provision of public service in education for that level.

7.16. An educational organization implementing PPKRS should have a material and technical base that ensures the conduct of all types of laboratory work And practical exercises, disciplinary, interdisciplinary and modular training, educational practice, provided for by the curriculum of the educational organization. The material and technical base must comply with the current sanitary and fire safety standards.

Scroll

offices, laboratories, workshops and other premises

Cabinets:

technical measurements;

materials science;

electrical engineering;

technical graphics;

life safety;

metalworking technologies and work in metalworking shops;

computer class.

Sports complex:

gym;

outdoor stadium general profile with obstacle course elements;

shooting range (in any modification, including electronic) or a place for shooting.

library, reading room with Internet access;

Assembly Hall.

The implementation of the PPCR should ensure:

performance by students of laboratory work and practical exercises, including, as a mandatory component, practical tasks using personal computers;

the development of professional modules by students in the conditions of the created appropriate educational environment in an educational organization or in organizations, depending on the specifics of the type of activity.

An educational organization must be provided with the necessary set of licensed software.

7.17. The implementation of the PPKRS is carried out by an educational organization in the state language of the Russian Federation.

The implementation of the PPKRS by an educational organization located on the territory of a republic of the Russian Federation may be carried out in the state language of the republic of the Russian Federation in accordance with the legislation of the republics of the Russian Federation. The implementation of the PPKRS by an educational organization in the state language of the Republic of the Russian Federation should not be carried out to the detriment of the state language of the Russian Federation.

VIII. Requirements for the results of mastering the training program for skilled workers, employees

8.1. Assessment of the quality of mastering the PPKRS should include ongoing monitoring of academic performance, intermediate and state final certification of students.

8.2. Specific forms and procedures for monitoring progress, intermediate certification for each discipline and professional module are developed by the educational organization independently and brought to the attention of students within the first two months from the start of training.

8.3. To certify students for the compliance of their personal achievements with the step-by-step requirements of the relevant PPKRS (current progress control and intermediate certification), funds of assessment tools are created to assess skills, knowledge, practical experience and mastered competencies.

Funds of assessment tools for intermediate certification in disciplines and interdisciplinary courses as part of professional modules are developed and approved by the educational organization independently, and for intermediate certification in professional modules and for the state final certification, they are developed and approved by the educational organization after a preliminary positive opinion of employers.

For intermediate certification of students in disciplines (interdisciplinary courses), in addition to teachers of a specific discipline (interdisciplinary course), teachers of related disciplines (courses) should be actively involved as external experts. In order to bring the programs of intermediate certification of students in professional modules as close as possible to the conditions of their future professional activity, the educational organization should actively involve employers as freelance experts.

8.4. The assessment of the quality of training of students and graduates is carried out in two main directions:

assessment of the level of mastering disciplines;

assessment of students' competencies.

For young men, an assessment of the results of mastering the basics of military service is provided.

8.5. Students who do not have academic debts and who have fully completed the curriculum or individual curriculum for PPKRS are allowed to the state final certification, unless otherwise established by the procedure for conducting the state final certification for educational programs of secondary vocational education.

8.6. The state final certification includes the defense of the final qualifying work (final practical qualifying work and written examination paper). Mandatory requirements- correspondence of the subject of the final qualifying work to the content of one or more professional modules; final practical qualifying work should provide for the complexity of the work not lower than the level of the profession of a worker, provided for by the Federal State Educational Standards of the secondary vocational education.

The state exam is introduced at the discretion of the educational organization.

8.7. In accordance with Part 6 of Article 68 of the Federal Law of December 29, 2012 N 273-FZ "On Education in the Russian Federation", students of the PPKRS who do not have secondary general education are entitled to pass the state final certification, which completes the development of educational programs of secondary general education. Upon successful completion of the specified state final certification by an accredited educational organization, students are issued a certificate of secondary general education.

_____________________________

*(1) Part 1 of Article 15 of Federal Law No. 273-FZ of December 29, 2012 "On Education in the Russian Federation" (Sobraniye Zakonodatelstva Rossiyskoy Federatsii, 2012, No. 53, Art. 7598; 2013, No. 19, Art. 2326 ).

*(2) In accordance with the Federal Law of March 28, 1998 N 53-FZ "On Military Duty and Military Service".

*(3) Collection of Legislation of the Russian Federation, 2012, N 53, Art. 7598; 2013, N 19, Art. 2326.

*(4) Clause 1 of Article 13 of Federal Law No. 53-FZ of March 28, 1998 "On Military Duty and Military Service" (Sobraniye Zakonodatelstva Rossiyskoy Federatsii, 1998, No. 13, Art. 1475; 2004, No. 35, Art. 3607; 2005, N 30, item 3111; 2007, N 49, item 6070; 2008, N 30, item 3616; 2013, N 27, item 3477).

*(5) Part 6 of Article 59 of Federal Law No. 273-FZ of December 29, 2012 "On Education in the Russian Federation" (Sobraniye Zakonodatelstva Rossiyskoy Federatsii, 2012, No. 53, Art. 7598; 2013, No. 19, Art. 2326 ).

Document overview

The federal state educational standard of secondary vocational education in the profession "Drafter-Designer" (151901.01) was approved.

The standard is mandatory for use by educational organizations that have the right to implement state-accredited training programs for skilled workers and employees in this profession in Russia.

The characteristic of training and professional activity of graduates is given. The requirements for the results of mastering the main educational program and its structure are determined.

2. A person who has an initial professional education without presenting requirements for work experience or a secondary (complete) one is appointed to the position of a draftsman. general education and special training according to the established program without presenting requirements for work experience.

3. Appointment to the position of a draftsman and dismissal from it is carried out by order of the director of the enterprise upon presentation

4. The draftsman must know:

4.1. Methodological and regulatory materials relating to the implementation of drawing work.

4.2. Methods and means of performing drawing work, the basics of technical drawing.

4.3. Tools and fixtures used in drawing.

4.4. Standards, specifications and instructions for drawing up drawings and other design documentation.

4.5. Fundamentals of labor organization.

4.6. Fundamentals of labor legislation.

4.7. Internal labor regulations.

4.8. Rules and norms of labor protection, industrial sanitation.

5. The draftsman reports directly

6. During the absence of the draftsman, his duties are performed by a person appointed in the prescribed manner. This person acquires the appropriate rights and is responsible for the proper performance of the duties assigned to him.

II. Job Responsibilities

Draftsman:

1. Performs drawing work (drawings of parts, assembly drawings, general arrangement drawings, dimensional and installation drawings and other design documentation) according to sketch documents or from life in the required scale in ink or pencil in compliance with the drawing rules.

2. Draws up diagrams, specifications, various statements and tables.

3. Makes the necessary inscriptions and affixes symbols on the drawings and other documents.

4. Performs individual official assignments of his immediate supervisor.

The draftsman has the right:

1. Get acquainted with the draft decisions of the organization's management regarding its activities.

2. On issues within its competence, submit proposals for consideration by the organization's management on improving the organization's activities and improving the working methods of employees; comments on the activities of employees of the organization; options for eliminating shortcomings in the organization's activities.

3. Request personally or on behalf of the management of the organization from the departments of the organization and other specialists the information and documents necessary to carry it out official duties.

4. Require the management of the organization to assist in the performance of his duties and rights.

IV. Responsibility

The draftsman is responsible for:

1. For improper performance or non-performance of their official duties under this job description, - within the limits determined by the current labor law Russian Federation.

2. For offenses committed in the course of carrying out their activities - within the limits determined by the current administrative, criminal and civil legislation of the Russian Federation.

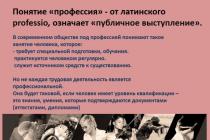

Draftsman-designer

There was a time when the creation of new machines and structures was embraced by the romance of lone inventors who themselves invented, were themselves the main practical manufacturers of parts of the product, its assemblers or direct supervisors and participants in the manufacture, assembly, testers, etc. Now the work of creating machines, in particular their design, is divided among different and many specialists.

Before the drawing needed by the worker in the factory shop falls into his hands, over this important technical document many people will work - copiers, photocopiers, even workers of the technical archive. One of the links in this chain of specialists, connecting design engineers, design technicians, on the one hand, and direct practical manufacturers of the product, on the other hand, is a draftsman who has received training in educational institution vocational education.

What does a draftsman do? Let's go to his workplace. It can be located in a design bureau or in the design department of an enterprise, in a design and research institute.

According to occupational health standards, the design department room has good general illumination. Each workplace, in addition, has an individual lamp. There is silence in the room. All this contributes to fruitful work.

The worker has a special drawing device - a drawing board, which consists of a drawing board and a special mechanical device (pantograph). The latter is equipped with two mutually perpendicular rulers that can be moved in the plane of the drawing board. Thanks to this device, there is no need to use a T-square (a T-shaped ruler known to every high school student for drawing mutually parallel lines), triangles, a protractor, and scale rulers.

The design of the drawing board allows you to perform graphic work both standing and sitting. In addition to the drawing board, the draftsman's workplace also has other equipment: a desk, a special chair with adjustable seat height, and a drawer for drawing tools. A set of drawing tools consists of a set of pencils of various hardness, patterns, various stencils, rulers, squares, and a preparation. In the preparation room - compasses, drawers, etc. Of course, there is ink at the workplace.

One of the types of work performed by a draftsman-designer is drawing working drawings of parts. Let's imagine that the factory should start production of a new car. This means that the workers who will take part in its manufacture and assembly must have such drawings that will indicate decisively everything they need to know: a specific grade of material, the required precision in processing parts (tolerances, dimensions), the required cleanliness of processing certain surfaces, graphic images of products, details in the required number of projections. All this information, which gives a comprehensive idea of a particular part, is expressed graphically in the drawing (by means of a schematic representation), as well as in the form of textual material. Part of the information is given in the form of special symbols. And all this must be done in accordance with strict rules, which are defined in special documents approved by state bodies - in State Standards (GOSTs).

We say: "Workers should have drawings ...", but the fact of the matter is that they do not yet exist. The drawings will appear at the hand of the draftsman-designer, but for now, in front of him lies the sketch made by the design engineer. In translation, "sketch" means a preliminary sketch. In our case, this is a drawing made by hand, without the help of drawing tools. At the same time, the sketch is made on the so-called visual scale, in which the proportions of the part and its elements in all the images taken should be ensured, but strict adherence to the scales provided for State standards, No. An experienced worker will be able to make a part according to a drawing made in the form of a sketch. Drawings intended for one-time use (for example, for the manufacture of a trial, prototype part) can be made in the form of sketches. A sketch can serve as a document for making a part. But we are considering the case when the plant began to produce a series of machines. Here we need not sketches, but drawings that meet all the requirements of GOSTs. Therefore, the sketch will serve here as a document not for the manufacture of the part, but for the draftsman-designer to complete the working drawing.

A working drawing may not necessarily be prepared according to a sketch, but according to a drawing in which the part of interest to us is depicted as an integral part of a product. The design of detail drawings depends, in particular, on the conditions technological process(casting, processing on various metal-cutting machines, etc.).

In order to build a drawing according to a sketch, one must carefully analyze the features of the latter, highlight the most important geometric relationships in it, mentally separating them from secondary ones. At the same time, it is important to outline a plan for constructing a drawing: what to draw first, what - after; what auxiliary lines will need to be drawn, that is, lines that should not be in the final form of the drawing, but which cannot be dispensed with during its construction; it is important to think about which parts of the contour are invisible and should be indicated by dashed lines, not solid lines, etc. To build a drawing according to a sketch does not mean just to redraw it well. This work requires a creative approach, the adoption of some independent decisions related to the graphic side of things.

It is very important that the worker be fascinated by the world of drawing elements in itself - a variety of lines (solid, dashed, dash-dotted, lines of different thicknesses), interfaces, hatching, fonts, inscriptions, symbols, etc.

Draftsmen-designers who love their work find and see in the drawings not only accuracy and rigor, but also beauty (for example, the beauty of the arrangement of images on a sheet, etc.).

In some cases, the draftsman-designer must himself build a sketch or drawing from nature. Before his eyes is a three-dimensional detail made by a craftsman for a prototype product. It is necessary to be observant, to carefully analyze mentally the signs of this detail, to determine how its visible appearance will change when it is transferred to the plane of the drawing sheet. Here it is necessary to mobilize knowledge about the rules, methods of projection, which are an important part of vocational training worker. When making a drawing from nature, the draftsman-designer makes the necessary measurements using the appropriate tools.

Sometimes a draftsman-designer may only have an assembly drawing at his disposal, and according to it, sketches or even working drawings of the necessary parts of the product must be made. These details have not yet been developed by anyone; this will have to be done independently by the draftsman-designer. The assembly drawing indicates which parts of the product with which parts and in what sequence should be connected, assembled. But after all, not everything in the new machine is new - it is assumed that standard parts that have justified themselves in the past will be widely used in it, ranging from nuts, bolts, ending with kinematic pairs (hinges, gears), etc. And if the design engineers themselves thought about the length and diameter of each bolt, about what kind of steel - carbon, alloy - or, maybe, to make it from brass, it would take too much time (not to mention that these engineers, drowning in details, would risk losing important ideas, ideas about technical specifications machines in general possible ways its improvement). The construction of sketches and working drawings according to the assembly drawing is called detailing. In carrying out this work, the draftsman-designer must show a lot of initiative, resourcefulness, independence and, of course, show versatile knowledge. It offers various reference manuals, sometimes voluminous, multivolume. You need to navigate them well and quickly.

One of the types of work entrusted to a draftsman-designer is the execution of simple assembly drawings, however, these drawings, under conditions modern technology nevertheless, they are quite complex, and their implementation requires a thorough preparedness of the worker.

In design practice, there are various methods for checking the correctness of a design solution even before all the details are made in kind, in metal. For example, it is important to check the so-called assembleability of the designed node. To do this, the draftsman-designer performs a control drawing of an assembly unit (carries out, as experts say, a control assembly, that is, draws an assembly drawing according to the working drawings of the parts). This requires the draftsman to have knowledge of building assembly drawings, a clear understanding of the interaction of the elements that make up this assembly. Based on the analysis of the drawings of the assembly unit, it is possible to determine whether the details of the assembly or assemblies, assemblies will fit each other during the future assembly, if necessary, to make improvements to the design project.

In addition to the above works, the draftsman-designer also performs others - draws diagrams (electrical, kinematic, hydraulic, etc., depending on the specialization profile of the design organization), prepares other design documents - specifications (tables, lists containing information about the components, name, number of parts of the product, elements of a set of products, etc.), statements. In addition, he makes changes to the relevant documentation adopted during the design development process. From time to time there is a revision of the standards governing the design of drawings (simplifications, new symbols, etc. are introduced). In this regard, it is required to update the current design documentation.

Working as a draftsman-designer, a person constantly improves his knowledge, business qualifications, professionally valuable qualities. This profession requires a good visual memory, spatial imagination, clear figurative and concrete thinking, accuracy of movements. People with low vision need to remember that the work of a draftsman-designer is associated with a load on the eyes.

The salary of a draftsman-designer depends on the length of service and qualifications. When the production team fulfills the plan, a quarterly progressive payment is established, there is a bonus system.

The profession of a draftsman-designer is obtained in Leningrad secondary vocational schools No. 1, 10, 21, 25, 44, 129 and 137, as well as in technical schools No. 40, 79 and 88. You can continue your education in many technical schools and institutes in the specialties of technology - designer, design engineer.