The visit of an inspector from Rospotrebnadzor makes any head of a catering enterprise nervous. The requirements for the mode of operation of such organizations are high and strictly regulated by regulatory documents, one of which is SanPiN 2.3.6.1079-01 for public catering.

From this article you will learn:

Sanitary rules for catering establishments - SanPiN 2.3.6.1079-01

The full name of the document under discussion is Sanitary Rules "Sanitary and epidemiological requirements for organizations Catering, production and turnover in them food products and food raw materials. SanPiN 2.3.6.1079-01". It has been in force since 2002 (of course, with regular additions).

SanPiN for public catering enterprises is a detailed set of rules, the main task of which is to prevent the outbreak and spread of infectious diseases, as well as cases of poisoning among the population.

General provisions and scope of SanPiN for public catering

SanPiN strictly regulates the following sanitary and hygienic standards:

- placement, arrangement, layout, sanitary and technical condition, maintenance of catering organizations;

- conditions of transportation, acceptance, storage, processing, sale of food raw materials, food products;

- technological processes of production, working conditions, .

All legal and individuals whose activities are related to catering both periodically (at social events) and on an ongoing basis. The form of ownership or departmental affiliation of the organization does not matter - the rules do not make any exceptions. Under them fall operating, under construction, reconstructed enterprises.

Also this document is the foundation for drawing up internal sanitary norms and rules at catering establishments that serve different groups population: children's institutions, health-improving, transport organizations and others.

Requirements for the arrangement and maintenance of premises, working conditions, equipment, inventory

Let's start with the first group of requirements. SanPiN for public catering requires that all aspects of the location of such enterprises meet sanitary standards. It is important that their activities do not have a negative impact on the living conditions of others. If the organization is located in non-residential premises residential building, then additional restrictions are imposed on its mode of operation.

The rules prohibit catering establishments from using their premises for any other activity, placing pets or birds on them, housing for staff, and allowing unauthorized persons into production facilities.

Separately, the conditions for the acceptance of raw materials and products, as well as the collection of garbage and food waste are stipulated.

A necessary condition for the work of the organization is the equipment of premises with internal water supply and sewerage systems. According to SanPiN norms for public catering, if any of these systems fails, the activity of the enterprise must be suspended.

Separately, storage standards are considered, as well as the use of equipment and inventory. To get an idea of how detailed the sanitary standards for public catering establishments regulate the mode of operation, consider just one example. According to the rules, manual washing of tableware should be done as follows:

- removal of food debris;

- washing in water with the addition of detergents in the first section of the bath;

- washing in a second bath with a water temperature of at least 40 ° C, with detergents in an amount half as much as in the first;

- rinsing in the third section with running water at a temperature of at least 65 ° C using a flexible hose with a shower head;

- drying on lattice shelves, racks;

- disinfection at the end of the working day.

Washing in a two-section bath differs from a three-section one in the 2nd stage, as well as in the fact that the dishes are washed with brushes.

Cutlery is washed by hand with detergents, rinsed in running water, calcined in ovens, bakers, dry ovens for 10 minutes. Brushes for washing dishes after the end of the process should be cleaned, soaked in water with a temperature of at least 45 ° C, adding detergents, then disinfected or boiled, rinsed with running water, dried, stored in a specially designated place.

Requirements for transportation, storage, processing of raw materials and production of products

Consider the requirements that SanPiN imposes on working with raw materials and finished products.

It can be used for transportation after thorough cleaning, if it has a valid sanitary passport. For the transportation of perishable products, only vehicles with isothermal equipment can be used. The storage of raw materials and products is also regulated very strictly down to their individual types.

Frozen meat should be stored on racks or underware, sausages and sausages - in the supplier's container or in production containers, fruits and greens - in boxes at a temperature not exceeding 12 ° C. In this case, the container must be provided with marking labels indicating the expiration date.

Further, SanPiN describes in detail the permitted methods of processing raw materials and manufacturing products (Chapter 8). Certain dishes and products, such as pasta in the Navy or dried fish, are not allowed to be made and served to visitors.

Finally, the rules clearly regulate the procedure for serving dishes, dispensing semi-finished products and culinary products.

Sanitary requirements for personal hygiene of personnel

Next important topic that is raised in the sanitary rules for public catering establishments is the personal hygiene of workers. An employee in the food industry must:

- your personal clothes, things to leave in the locker room;

- use only special clothes, keep it clean;

- remove these clothes before going to the toilet, and then wash your hands thoroughly with soap and water;

- before the start of the shift, wash hands with soap, hide hair under a cap, scarf or net, remove jewelry, watches, pins;

- at the first sign of a cold, problems with digestion, suppuration, cuts or burns, contact the administration of the enterprise;

- notify management of any intestinal diseases from members of their family;

- , do not eat food in the workplace.

Organization of production control

SanPiN on public catering obliges all employers in their area of responsibility, as well as to conduct laboratory tests on microbiological indicators. The procedure for these activities must be coordinated with Rospotrebnadzor.

Requirements for compliance with sanitary rules

The next part of SanPiN essentially summarizes the basic requirements for the mode of operation of the enterprise. In accordance with it, the management is required to ensure the implementation of existing sanitary rules, to hire only those who have undergone professional, hygienic training and certification. You will find a complete list of requirements in paragraph 15.1 of the sanitary rules.

Watch out, penalty!

Violation of SanPiN requirements for catering establishments can lead to administrative penalty according to .

- a fine of 2,000-3,000 rubles or suspension of activities for up to 90 days for officials;

- a fine of 20,000-30,000 rubles or suspension of activities for up to 90 days for legal entities.

Microclimate and MPC parameters

Separately, it is worth mentioning the requirements for maintaining the microclimate and MPC in industrial and warehouse premises. According to the sanitary rules for catering establishments , all these areas should and preferably have water heating systems. Heating appliances must be kept clean and placed away from refrigeration equipment.

The characteristics of air conditioning, heating, artificial and natural lighting systems must fully comply with the requirements of sanitary rules.

The procedure for conducting medical examinations of personnel

Finally, we will consider the rules for conducting medical examinations employees. Of course, before starting work in a catering establishment, a future employee must undergo a preliminary medical examination. In the future, he will periodic medical examinations, professional hygienic training, certification. The same applies to students before the field trip.

In accordance with the norms of SanPiN for public catering, all the results of medical examinations, marks on the passage of hygienic training and certification must be entered

Decree

Chief State Sanitary Doctor of the Russian Federation dated November 8, 2001 No. 31

"On the Enactment of Sanitary Rules"

On the basis of the Federal Law "On the sanitary and epidemiological well-being of the population" dated March 30, 1999 No. 52-FZ and the Regulations on state sanitary and epidemiological regulation, approved by the Government Russian Federation dated July 24, 2000 No. , I decide:

1. To put into effect the sanitary rules “Sanitary and epidemiological requirements for public catering organizations, the production and circulation of food products and food raw materials in them. SanPiN 2.3.6.1079-01 "approved by the Chief State Sanitary Doctor of the Russian Federation on November 6, 2001, from February 1, 2002.

2. From the moment of the introduction of the said sanitary and epidemiological rules, the sanitary rules “Sanitary and epidemiological requirements for public catering organizations, the production and turnover of food raw materials and food products in them” shall be considered invalid. SanPiN 2.3.6.959-00 ", approved by the Chief State Sanitary Doctor of the Russian Federation on July 31, 2000.

G.G. Onishchenko

Registration number 3077

2.3.6. CATERING ORGANIZATIONS

Sanitary and epidemiological requirements

to public catering organizations, production

and turnover capacity of food products in them

and food raw materials

Sanitary and epidemiological rules

SP 2.3.6.1079-01

. General provisions and scope

1.1. These Sanitary and Epidemiological Rules (hereinafter referred to as the Sanitary Rules) have been developed in order to prevent the occurrence and spread of infectious and infectious diseases(poisoning) among the population of the Russian Federation and determine the basic sanitary and hygienic standards and requirements for the placement, arrangement, planning, sanitary and technical condition, maintenance of organizations, conditions for transportation, acceptance, storage, processing, sale of food raw materials and food products, technological production processes , as well as to working conditions, compliance with the rules of personal hygiene of workers.

1.2. Sanitary rules apply to existing, under construction and reconstructed public catering organizations, regardless of ownership and departmental affiliation, including when preparing food and drinks, storing them and selling them to the public.

These sanitary rules are binding on all citizens, legal entities And individual entrepreneurs whose activities are related to the organization of catering for the population, including during the period of mass public events (fairs, sports competitions, olympiads, university games, cultural and entertainment, rallies and other similar public events).

1.3. These rules are the basis for the development of sanitary norms and rules for public catering organizations that provide catering for various groups of the population (children's, adolescents, medical and recreational institutions, catering in transport, etc.).

. Accommodation Requirements

2.1. Placement of organizations, provision of land plots, approval project documentation for construction and reconstruction, commissioning is allowed if there is a sanitary and epidemiological conclusion on their compliance with sanitary rules and norms.

2.2. Organizations can be located both in a separate building and in an attached, built-in-attached to residential and public buildings, in non-residential floors of residential buildings, in public buildings, as well as on the territory of industrial and other facilities for servicing working personnel. At the same time, the conditions of living, rest, treatment, and work of people should not worsen.

When placing public catering organizations in attached, built-in and attached to residential and public buildings, in non-residential floors of residential buildings, in public buildings, hygienic standards for noise levels, infrasound, vibration, electromagnetic fields in the premises of residential, public buildings and on the territory of residential development must be observed , as well as maximum permissible concentrations and approximate safe levels of exposure to pollutants in the atmospheric air of populated areas.

Production workshops of organizations are not recommended to be placed in basements and semi-basements.

Organizations located in residential buildings should have entrances isolated from the residential part of the building. Reception of food raw materials and foodstuffs from the courtyard of a residential building, where windows and entrances to apartments are located, is not allowed. Loading should be carried out from the ends of residential buildings that do not have windows, from underground tunnels on the side of highways in the presence of special loading rooms.

(Changed edition. Rev. No. 4)

2.3. Orientation, placement of production and storage facilities, their layout and equipment must ensure compliance with the requirements of sanitary legislation, technological production regulations, quality and safety finished products and the working conditions of the workers.

2.4. When designing, building new and reconstructing existing organizations, taking into account the range of products being developed, one should be guided by current building codes, technological design standards for public catering organizations, as well as the requirements of these Rules .

2.5. Organizations do not place premises for housing, do not carry out work and services not related to the activities of public catering organizations, and do not keep pets and birds.

Unauthorized persons should not be in production and storage rooms.

2.6. For the collection of garbage and food waste on the territory, separate containers with lids should be provided, installed on hard-surfaced sites, the dimensions of which exceed the base area of the containers by 1 m in all directions.

It is allowed to use other special closed structures for collecting garbage and food waste.

Garbage bins are cleaned when filling no more than 2/3 of their volume, after which they are cleaned and disinfected using products authorized by the bodies and institutions of the State Sanitary and Epidemiological Service in the prescribed manner.

The waste collection site is located at a distance of at least 25 m from residential buildings, playgrounds and recreation areas.

The sites should be located on the side of the carriageway of roads and not located in the courtyards of residential buildings.

2.8. The territory of the organization must be landscaped and kept clean.

III. Requirements for water supply and sewerage

3.1. Organizations, regardless of the form of ownership, capacity, location, are equipped with internal water supply and sewerage systems.

Organizations are supplied with water by connecting to a centralized water supply system; in its absence, an internal water supply system is equipped with water intake from an artesian well, wells, and capturing.

Sources of water supply for newly built, reconstructed and operating enterprises, stand-alone stand-alone hot water supply devices with wiring through the system must meet the requirements of the relevant sanitary rules.

The location, equipment, maintenance of water intake facilities (shaft, tubular wells, capturing of springs) and the territory adjacent to them must comply with sanitary rules.

3.2. The quality of water in the organization's water supply systems must meet the hygienic requirements for water quality. centralized systems drinking and decentralized water supply.

3.3. The amount of water used by the organization must fully meet its needs. Water consumption rates must comply with Table. And .

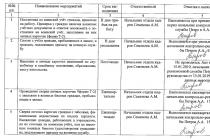

Water consumption rates for the preparation of semi-finished products * 1)

___________

* 1) Does not apply to semi-finished products of a high degree of readiness.

table 2

Estimated second water consumption and the percentage of simultaneous operation of equipment

| Equipment | Water consumption, l/s | Percentage of simultaneous action |

|

| Washing baths | |||

| Sinks (industrial) | |||

| Dishwashers | |||

| Potato washers, potato peelers and boilers | |||

| Boilers | |||

| Ice makers | |||

| Notes. 1. The water consumption of refrigeration units should be taken according to technical specification these settings. 2. Hot water supply should be designed to washing baths and industrial sinks, as well as to watering taps for washing grease traps, dirt traps and scum collectors. |

|||

All production shops equipped with sinks with hot and cold water supply. At the same time, such designs of mixers should be provided that exclude re-contamination of hands after washing.

Hot and cold water is supplied to all wash basins and sinks with faucets installed, as well as, if necessary, to technological equipment.

The hot water temperature at the point of disassembly must be at least 65 °C.

For hot water networks, materials are used that can withstand temperatures above 65 ° C.

3.4. It is forbidden to use hot water from the water heating system for technological, household purposes, as well as processing of technological equipment, containers, inventory and premises.

Organizations are prohibited from using imported water.

3.5. In the absence of hot or cold water, the organization suspends its work.

(Revised edition, Rev. No. 2)

3.6. The device of the sewerage system of organizations must comply with the requirements of the current building codes for sewerage, external networks and structures, internal water supply and sewerage of buildings, as well as the requirements of these Rules .

3.7. Assignment of industrial and household Wastewater carried out in the system of centralized sewer treatment facilities, in their absence, into the system of local sewage treatment plants, must meet the requirements of the relevant sanitary rules.

The internal sewerage system for industrial and domestic wastewater must be separate with independent discharges into the on-site sewerage network.

The level of release of industrial effluents is equipped above the level of release of household and fecal effluents.

Premises with the presence of drains, washing baths, sinks, toilet bowls are not located below the level of on-site sewerage adjacent to the food facility.

Horizontal sewerage outlets from all industrial premises, regardless of the number of sanitary devices, have pipe cleaning devices.

At the end sections of the horizontal sewer outlets, "breathing" risers are arranged to eliminate the suction effect during salvo discharges of wastewater from the equipment.

(Changed edition, Rev. No. 2)

3.8. Production equipment and washing baths are connected to the sewerage network with an air gap of at least 20 mm from the top of the intake funnel. All waste receivers internal sewerage have hydraulic locks (siphons).

3.9. Discharge into open water bodies and the adjacent territory of untreated sewage, as well as the installation of absorbing wells, is not allowed.

3.10. Laying of internal sewer networks with domestic and industrial wastewater is not carried out under the ceiling of dining rooms, production and storage facilities of organizations. Sewer risers with industrial effluents are allowed to be laid in production and storage facilities in plastered boxes without revisions.

Household sewage risers from the upper floors of residential buildings and buildings for other purposes are allowed to be laid only in technological channels (horizontal, vertical).

Sewer risers are not laid in dining rooms, production and storage facilities.

3.11. In premises located in residential buildings and buildings for other purposes, household and industrial sewerage networks of organizations are not combined with the utility and fecal sewerage of these buildings.

3.12. In sanitary facilities, showers and bathrooms located above organizations, the floors must be waterproofed.

3.13. All production workshops, washing, defroster, loading, storage of food waste should be equipped with drain ladders with a floor slope towards them.

In the vestibule of the toilet for personnel, a separate tap with a mixer at a level of 0.5 m from the floor should be provided for the intake of water intended for washing floors, as well as a drain ladder with a slope towards it.

3.14. All stationary organizations are equipped with toilets and sinks for washing the hands of visitors. Combining toilets for staff and visitors is not allowed.

Temporary quick service organizations (pavilions, tents, vans, etc.) are recommended to be placed in places equipped with public toilets.

In all organizations under construction and reconstruction, toilet bowls and sinks for washing hands of personnel should be equipped with devices that exclude additional contamination of hands (elbow, pedal drives, etc.).

. Requirements for working conditions in industrial premises

4.1. The working conditions of employees of organizations must meet the requirements of the current regulatory documents in the field of occupational health, approved in the prescribed manner.

Sanitary provision of employees is carried out in accordance with the current sanitary rules, building codes for administrative and amenity buildings.

All organizations create the necessary conditions to comply with the rules of personal hygiene of the staff (availability of soap, towels, toilet paper and so on.).

4.2. The indicators of the microclimate of industrial premises and premises for visitors must comply with the hygienic requirements for the microclimate of industrial premises.

4.3. When using air conditioning systems, the microclimate parameters in industrial premises must comply with the optimal values of sanitary standards. In the presence of ventilation systems with a mechanical or natural stimulus, the parameters must meet acceptable standards.

4.4. Production, auxiliary and sanitary premises are equipped with forced-air and exhaust mechanical ventilation in accordance with the requirements of the current rules and regulations.

In the premises for finishing confectionery products, the supply ventilation system is carried out with an anti-dust and bactericidal filter, which ensures the supply of clean air in this room.

Openings of ventilation systems are closed with a fine-meshed polymer mesh.

Amenity premises (toilets, pre-showers, women's hygiene rooms) are equipped with autonomous exhaust ventilation systems, mainly with natural motivation.

In mechanical supply ventilation systems, it is recommended to provide for the purification of the supplied outside air and its heating during the cold season. Air intake for supply ventilation is carried out in the zone of least pollution at a height of at least 2 m from the ground.

It is recommended to equip the premises of the loading room, expedition, vestibules with thermal curtains to prevent the ingress of outside air during the cold season.

4.5. Equipment and washing baths, which are sources of increased emissions of moisture, heat, gases, are equipped with local exhaust systems with predominant exhaust in the zone of maximum pollution.

4.6. The device and equipment for emissions of local exhaust ventilation systems should not affect the deterioration of the living conditions and stay of people in residential buildings, premises and buildings for other purposes.

The exhaust ventilation system of organizations located in buildings for other purposes is equipped separately from the ventilation system of these buildings. Exhaust ventilation shafts protrude above the roof ridge or flat roof surface to a height of at least 1 m.

4.7. The organization ensures the air-thermal balance of the premises.

Supply air supply falls on the cleanest premises. To reduce aerodynamic resistance to air movement in ventilation systems, air ducts are made with a minimum number of turns.

4.8. Permissible values of the intensity of thermal exposure at workplaces from production equipment should not exceed 70 W / m 2 with the irradiated surface of the human body 25 - 50%. To prevent the adverse effects of infrared radiation on the body of cooks, confectioners should:

Apply sectional-modular equipment;

Fill the working surface of the plates with dishes as much as possible;

Timely turn off sections of electric stoves or switch to a lower power;

At workplaces near stoves, stoves, ovens and other equipment that works with heating, apply air showering;

To regulate intra-shift modes of work and rest of workers.

4.9. The content of harmful substances in the air of the working area of industrial premises should not exceed the maximum permissible concentrations (MPC) of harmful substances in the air of the working area.

4.10. To prevent the formation and entry into the air of industrial premises of harmful substances, it is necessary:

Strictly observe the technological processes of cooking;

When operating gas stoves, ensure complete combustion of fuel;

Flour sifting operations powdered sugar and other bulk products, to produce at a workplace equipped with local exhaust ventilation;

All work should be carried out only when the supply and exhaust or local exhaust ventilation is turned on.

4.11. In newly built and reconstructed organizations, it is not allowed to install stoves that run on coal, wood, solid fuel, etc.

It is allowed to cook dishes on the grill in public catering establishments located in separate buildings, subject to the use of modern equipment.

(Changed edition. Rev. No. 4)

4.12. Production, auxiliary premises and premises for visitors are provided with heating (water or other types) in accordance with the requirements for heating, ventilation and air conditioning, as well as with the requirements of these Rules .

In organizations, it is preferable to provide water heating systems.

Heating appliances should be regularly cleaned of dust and dirt and should not be placed near refrigeration equipment.

4.13. Natural and artificial lighting in all production, storage, sanitary and administrative premises must comply with the requirements for natural and artificial lighting, as well as the requirements of these Rules . This makes maximum use of natural light.

4.14. In the shop for the preparation of cold dishes and snacks, confectionery shops, where cream is prepared and the finishing of cakes and pastries, when linking the project, the north-west orientation is provided, as well as the use of devices for protection against insolation (blinds, special glasses and other devices that reflect thermal radiation).

4.15. To illuminate industrial premises and warehouses, lamps in moisture and dust protection design are used. Glitter should not be created at workplaces. Fluorescent lamps placed in rooms with rotating equipment (universal drives, cream beaters, dough mixers, circular knives) must have lamps installed in antiphase. Luminaires for general lighting are placed evenly throughout the room. Luminaires are not placed above stoves, process equipment, cutting tables. If necessary, workplaces are equipped additional sources lighting. Lighting devices must have protective fittings.

4.16. Lighting indicators for industrial premises must comply with established standards.

4.17. Lighting fixtures, fittings, glazed surfaces of windows and openings are kept clean and cleaned as they become dirty.

4.18. Permissible levels of noise and vibration at workplaces in industrial premises, dining halls and sites of organizations must comply with the hygienic requirements for noise and vibration levels at workplaces, in residential and public buildings.

4.19. When designing, reconstructing and operating premises that house noise-generating equipment, measures should be taken to protect people from harmful effects noise, taking into account compliance with current regulatory requirements.

4.20. To protect workers from noise in the premises where noise-generating equipment is located, the following measures are taken to protect against its harmful effects:

Finishing rooms with sound-absorbing materials;

Installation of electric motors on shock absorbers using sound-absorbing casings, installation of equipment on vibration-absorbing foundations;

Timely elimination of malfunctions that increase noise during equipment operation;

Constant monitoring of the fastening of moving parts of machines and mechanisms, checking the condition of shock-absorbing pads, lubrication, etc.;

Timely preventive maintenance and repair of equipment;

Operation of equipment in the modes specified in the passport of manufacturers;

Placement of workplaces, machines and mechanisms in such a way that the impact of noise on workers is minimal;

Placement of jobs for waiters, bartenders, bartenders in dining halls in the least noisy places, remote from the stage, acoustic systems;

Limiting the output power of musical arrangements in the premises for visitors;

Organization of places for short-term rest of employees in rooms equipped with sound insulation and sound absorption;

Installation in hot shops of suspended ceilings at a distance of 40 - 50 cm from the ceiling.

4.21. Total duration working time (shift) in organizations is established in accordance with the current labor legislation.

4.22. All labor-intensive operations associated with lifting and moving heavy objects are mechanized.

4.23. Pregnant women working at stoves, confectionery ovens, ovens, should be transferred, on the conclusion of a doctor, to work that is not associated with intense heat exposure and manual carrying of heavy loads.

. Requirements for the arrangement and maintenance of premises

5.1. Space-planning and design solutions for premises should provide for a sequence (flow) of technological processes that exclude oncoming flows of raw materials, raw semi-finished products and finished products, used and clean utensils, as well as oncoming traffic of visitors and staff.

At pre-preparation organizations working on semi-finished products, work on raw materials is not carried out.

5.2. The set and area of premises should correspond to the capacity of organizations and ensure compliance with sanitary rules and regulations.

For temporary storage of ready-made meals before their sale, catering establishments must provide premises equipped with refrigerators and racks.

(Changed edition. Rev. No. 4)

5.3. Technological equipment is located so as to ensure free access to it and compliance with safety regulations.

5.4. During the work of quick service organizations on semi-finished products of a high degree of readiness, which use a small-sized specialized technological equipment, utensils and disposable appliances, a single-room layout is allowed with the allocation of separate working areas equipped with equipment.

When using tableware, tea utensils, reusable appliances, a dishwasher is installed.

(Changed edition, Rev. No. 2 .)

5.5. The walls of industrial premises to a height of at least 1.7 m are finished with facing tiles or other materials that can withstand wet cleaning and disinfection. Ceilings are plastered and whitewashed or finished with other materials. The floors are made of impact-resistant non-slip materials and are sloped towards the drains.

Ceilings and walls of production and auxiliary premises of confectionery shops are painted as needed, but at least once a year.

5.6. Warehouse walls and ceilings are plastered and whitewashed. Walls to a height of at least 1.7 m are painted with moisture-resistant paints for interior decoration.

The floors are made of moisture-resistant materials of increased mechanical strength (impact-resistant) with sealing of building structure interfaces with a fine-mesh metal mesh, steel sheet or cement-sand mortar with long metal chips. Floors along the ways of loading raw materials and food in warehouses and production facilities should not have thresholds. The loading room is equipped with a platform, a canopy.

5.7. Finishing of dining rooms (halls) must be resistant to sanitation and disinfection.

The device of decorative screens above the registers of heating systems from polymeric and synthetic materials is not carried out. Decorative panels for these purposes are made of metal and easily removable.

5.8. For interior decoration of premises, materials are used that are approved by the bodies and institutions of the State Sanitary and Epidemiological Service in the prescribed manner.

5.9. In the shops for the preparation of cold dishes, soft ice cream, in the confectionery shops for the preparation of cream and finishing of cakes and pastries, in the shops and areas for portioning ready meals, packaging and forming sets of ready meals, bactericidal lamps are installed, which are used in accordance with the operating instructions .

(New edition. Change No. 4)

5.10. It is not allowed to store breakable objects, mirrors, indoor plants in production workshops.

5.11. All organization premises must be kept clean. Current cleaning is carried out constantly, in a timely manner and as needed.

Wet cleaning with the use of detergents and disinfectants is carried out daily in the production workshops.

Cleaning of the dining table is obligatory after each visitor.

5.12. General cleaning and disinfection is carried out at least once a month. If necessary, disinfestation and deratization of premises is carried out in accordance with the established procedure.

5.13. For cleaning production, storage, auxiliary premises, as well as toilets, separate equipment is allocated, which is stored in specially designated places, as close as possible to the places of cleaning. The inventory for washing toilets has a signal color and is stored separately.

At the end of the cleaning at the end of the shift, all cleaning equipment is washed using detergents and disinfectants, dried and stored clean in the place designated for it.

5.14. In order to prevent the occurrence and spread of infectious diseases, cleaning of production, auxiliary, storage and amenity premises is carried out by cleaners, and cleaning of workplaces is carried out by workers at the workplace. Special personnel are assigned to clean the toilets.

Cleaners should be provided with enough cleaning equipment, rags, detergents and disinfectants.

5.15. Organizations use detergents and disinfectants approved by the bodies and institutions of the State Sanitary and Epidemiological Service in accordance with the established procedure, which are used in strict accordance with the attached instructions and are stored in specially designated places in the manufacturer's packaging.

5.16. In public catering organizations, cosmetic repairs (whitewashing and painting of premises, preventive maintenance of sanitary and technological equipment) should be carried out as necessary and its painting.

(Clause 5.16 was introduced additionally. Amendment No. 4)

. Requirements for equipment, inventory, utensils and containers

6.1. Organizations are provided with sufficient necessary equipment and items of material and technical equipment.

When organizing meals for participants in mass public events, a sufficient amount of dishes should be provided. When a public catering organization provides catering services (cooking and delivering them to the place of order, heating dishes, setting the table, cleaning dishes, premises and territory, carried out by field staff), the number of tableware and cutlery is completed in accordance with the number of servings for a single use . The supply of clean wine glasses and cups is calculated for 2-3 times the reception of drinks by visitors.

(Changed edition. Rev. No. 4)

6.2. Technological equipment, inventory, utensils, containers are made from materials permitted by the bodies and institutions of the State Sanitary and Epidemiological Service in the prescribed manner.

6.3. During the operation of technological equipment, the possibility of contact between raw and ready-to-eat products is excluded.

For grinding raw and heat-treated food products, as well as for raw semi-finished products and culinary semi-finished products of a high degree of readiness, separate technological equipment must be provided and used, and in universal machines - replaceable mechanisms.

(Changed edition. Rev. No. 4)

6.4. Sanitization of technological equipment is carried out as it becomes contaminated and at the end of work.

Production tables at the end of work are thoroughly washed using detergents and disinfectants, washed with hot water at a temperature of 40 - 50 ° C and wiped dry with a dry clean cloth.

6.5. In order to prevent infectious diseases, cutting equipment is assigned to each workshop and has a special marking.

Cutting boards and knives are marked in accordance with the product processed on them: "CM" - raw meat, "SR" - raw fish, "SO" - raw vegetables, "VM" - boiled meat, "VR" - boiled fish, "VO "- boiled vegetables, "MG" - meat gastronomy, "Greens", "KO" - pickled vegetables, "Herring", "X" - bread, "RG" - fish gastronomy.

It is allowed to apply color marking to cutting equipment along with letter marking in accordance with the product being processed on them. Cutting equipment for finished and raw products should be stored separately.

(Changed edition. Rev. No. 4)

6.6. The deck for cutting meat is installed on a crosspiece or a special stand, fastened with metal hoops, daily after work is cleaned with a knife and sprinkled with salt. Periodically, as necessary, the deck is cut and planed.

After each technological operation cutting equipment (knives, boards, etc.) is subjected to sanitization: mechanical cleaning, washing with hot water with detergents, rinsing with hot running water. Store inventory in a designated area.

6.8. The number of simultaneously used tableware and appliances should meet the needs of the organization.

6.9. It is recommended to use stainless steel utensils for cooking and storing prepared food. Aluminum and duralumin utensils are used only for cooking and short-term storage of food.

6.10. Dishes with cracks, chips, broken edges, deformed, with damaged enamel are not used.

6.11. Mechanical washing of dishes on specialized washing machines is carried out in accordance with the attached instructions for their operation.

For washing dishes by hand, it is necessary to provide three-section baths for tableware, two-section - for glassware and cutlery.

Washing tableware and appliances in a two-section bath is allowed in organizations with a limited range.

(Changed edition. Rev. No. 2)

6.12. In beer bars, mugs, glasses, glasses are washed with hot water at least 45 - 50 ° C using detergents and disinfectants.

For rinsing glasses, glasses, mugs, syringe installations are additionally equipped.

6.13. Upon failure dishwasher, the absence of conditions for manual washing of dishes, as well as disposable tableware and appliances, the work of the organization is not carried out.

6.14. Washing tableware by hand is carried out in the following order:

Mechanical removal of food residues;

Washing in water with the addition of detergents in the first section of the bath;

Washing in the second section of the bath in water with a temperature of at least 40 ° C and the addition of detergents in an amount two times less than in the first section of the bath;

Rinsing dishes in metal mesh with handles in the third section of the bath with hot running water at a temperature of at least 65 ° C using a flexible hose with a shower head;

Drying dishes on lattice shelves, racks.

6.15. At the end of the working day, all tableware and cutlery are disinfected with products in accordance with the instructions for their use.

6.16. Washing of kitchen utensils is carried out in two-section baths in the following order:

Mechanical cleaning of food residues;

Washing with brushes in water with a temperature not lower than 40 ° C with the addition of detergents;

Rinsing with running water with a temperature not lower than 65 ° C;

Drying in an overturned form on lattice shelves, racks.

6.17. Cutlery, when processed by hand, is subjected to washing with the use of detergents, subsequent rinsing in running water and calcination in ovens, bakers, dry ovens for 10 minutes.

6.18. Clean kitchen utensils and utensils are stored on racks at a height of at least 0.5 m from the floor.

Clean tableware is stored in closed cabinets or on racks.

Clean cutlery is stored in the hall in special cassette boxes, handles up. Storing them on trays in bulk is not allowed. Cassettes for cutlery are daily sanitized.

6.19. Brushes for washing dishes after finishing work are cleaned, soaked in hot water at a temperature not lower than 45 ° C with the addition of detergents, disinfected (or boiled), washed with running water, then dried and stored in a specially designated place.

Brushes with mold and visible dirt, as well as sponge material, the quality of which cannot be processed, are not used.

6.20. Trays for visitors after each use are wiped with clean napkins. Trays deformed and with visible contamination are not used. At the end of the work, the trays are washed with hot water with the addition of detergents and disinfectants, rinsed with warm running water and dried. Store clean trays in designated areas on the sales floor, separate from used trays.

6.21. In washing departments, instructions are posted on the rules for washing dishes and equipment, indicating the concentrations and volumes of detergents and disinfectants used.

6.22. Washing of returnable containers in procurement organizations and in specialized workshops is carried out in specially designated rooms equipped with bathtubs or washing machines using detergents.

VII. Requirements for the transportation, receipt and storage of raw materials, food products

7.1. In order to prevent the emergence and spread of mass infectious diseases, the transportation of raw materials and food products is carried out by special clean vehicles, for which a sanitary passport is issued in accordance with the established procedure.

7.2. The body of the vehicle is upholstered from the inside with a material that can be easily sanitized and equipped with racks.

7.3. Persons accompanying food raw materials and food products on the way and performing their loading and unloading use sanitary clothing (robe, gloves, etc.), have personal medical book of the established sample with marks on the passage of medical examinations, results laboratory research and passing professional hygienic training and certification.

7.4. Perishable and especially perishable products are transported by refrigerated or isothermal transport, which ensures the preservation of temperature conditions of transportation. The quantity of perishable products supplied must correspond to the capacities of the refrigeration equipment available in the organization.

Culinary and confectionery products are transported in vehicles specially designed for this purpose in labeled and clean containers.

7.5. Shipping containers are marked in accordance with the regulatory and technical documentation corresponding to each type of product.

The sale of products outside the organization in consumer packaging is carried out in the presence of information provided for by the current hygiene requirements to the quality and safety of food raw materials and food products.

7.6. To prevent the occurrence and spread of mass non-communicable diseases (poisoning), transportation of food products together with toxic, pungent, radioactive and other dangerous substances is not allowed. The use of specialized transport intended for the transport of food products (regardless of their packaging) for other purposes is not allowed.

Food raw materials and finished products during transportation should not come into contact with each other.

7.7. Food raw materials and food products entering the organization must comply with the requirements of regulatory and technical documentation and be accompanied by documents confirming their quality and safety, and be in a serviceable clean container.

7.8. To prevent the emergence and spread of infectious diseases and mass non-infectious diseases (poisoning), it is prohibited to take in the organization:

Food raw materials and food products without documents confirming their quality and safety;

Meat and offal of all types of farm animals without stamps and veterinary certificates;

Fish, crayfish, poultry without a veterinary certificate;

Ungutted poultry (except game);

Eggs with contaminated shells, with a notch, “tek”, “battle”, as well as eggs from farms that are unfavorable for salmonellosis, duck and goose eggs;

Canned food with a breach in the tightness of cans, bombed, "crackers", cans with rust, deformed, without labels;

Cereals, flour, dried fruits and other products infected with granary pests;

Vegetables and fruits with mold and signs of rot;

Mushrooms are inedible, not cultivated edible, wormy, wrinkled;

Food products with expired shelf life and signs of poor quality;

Homemade products.

7.9. Products should be stored in the manufacturer's containers (barrels, boxes, flasks, cans, etc.), if necessary, transferred to a clean, labeled industrial container in accordance with the type of product.

7.10. Products without packaging are weighed in containers or on clean paper.

7.11. Products should be stored according to the accepted classification by type of product: dry (flour, sugar, cereals, pasta, etc.); bread; meat; fish; milk fat; gastronomic; vegetables and fruits.

Raw materials and finished products should be stored in separate refrigerators. In small organizations that have one refrigerating chamber, as well as in the chamber of the daily supply of products, their joint short-term storage is allowed in compliance with the conditions of the commodity neighborhood (on separate shelves, racks).

When storing food products, it is necessary to strictly observe the rules of the commodity neighborhood, warehousing standards, expiration dates and storage conditions. Products with a specific smell (spices, herring, etc.) should be stored separately from products that perceive foreign odors (butter, cheese, eggs, tea, salt, sugar, etc.).

7.12. Storage of especially perishable products is carried out in accordance with the hygienic requirements for the conditions and terms of storage of especially perishable products.

7.13. Refrigerators for food storage should be equipped with easy-to-clean racks, condensate collection and drainage systems, and, if necessary, hanging beams with tinned or stainless steel hooks.

7.14. Chilled meat carcasses, half carcasses, quarters are hung on hooks so that they do not come into contact with each other, with the walls and floor of the room. Frozen meat is stored on racks or stockpiles.

7.15. By-products are stored in the supplier's container on racks or pedestals.

7.16. Frozen or chilled poultry is stored in the supplier's container on racks or pedestals, stacked in stacks; for better air circulation between the boxes (boxes) it is recommended to lay slats.

7.17. Frozen fish (fish fillet) is stored on racks or bins in the supplier's container.

7.18. Sour cream, cottage cheese are stored in a container with a lid. It is not allowed to leave spoons, shoulder blades in a container with cottage cheese and sour cream.

7.19. Butter is stored in factory containers or bars wrapped in parchment, in trays, melted butter - in the manufacturer's container.

7.20. Large cheeses are stored without containers on clean racks. When laying cheeses one on top of the other, cardboard or plywood is laid between them.

Small cheeses are stored in consumer containers on shelves or racks.

7.21. Finished meat products (sausages, hams, frankfurters, sausages) are stored in the supplier's container or production container.

7.22. Eggs in boxes are stored on pallets in dry, cool rooms. Egg powder is stored in a dry room, melange - at a temperature not exceeding minus 6 °C.

7.23. Cereals and flour are stored in bags on pallets in stacks at a distance of at least 15 cm from the floor.

7.24. Pasta, sugar, salt are stored in the supplier's containers on racks or pedestals.

7.25. Tea and coffee are stored on racks in dry ventilated rooms.

7.26. Bread is stored on racks, in cabinets. It is recommended to allocate a separate pantry for storing bread. Rye and wheat bread are stored separately.

Doors in cabinets for bread should have holes for ventilation. When cleaning cabinets, crumbs should be swept off the shelves with special brushes and at least once a week, thoroughly wipe the shelves using a 1% solution of acetic acid.

7.27. Potatoes and root crops are stored in a dry, dark room; cabbage - on separate racks, in chests; pickled, salted vegetables - in barrels, at a temperature not exceeding 10 ° C. Fruits and greens are stored in boxes in a cool place at a temperature not exceeding 12 ° C.

7.28. Frozen vegetables, fruits, berries are stored in the supplier's container in low-temperature refrigerators.

7.29. The marking label of each container indicating the expiration date of this type of product should be kept until the product is fully used.

VIII. Requirements for processing raw materials and manufacturing products

8.1. When preparing dishes, culinary and confectionery products, it is necessary to strictly observe the flow of technological processes.

Preparation of dishes, culinary and confectionery products is carried out by catering staff with hygienic training. It is not recommended to involve personnel for the simultaneous implementation of work within the framework of various technological processes for the processing of food products.

(Changed edition. Rev. No. 4)

8.2. In cases of developing new recipes, as well as making changes to existing ones related to changes in production technology, the use of new, non-traditional raw materials, when reviewing the shelf life and storage conditions of food products, using new materials and equipment that may affect the safety indicators of finished products , the sanitary and epidemiological conclusion of the bodies and institutions of the State Sanitary and Epidemiological Service is issued for the formulations in the prescribed manner.

Production of products must be carried out according to technical documentation developed in accordance with the procedure established by law.

When holding mass public events, in order to prevent the occurrence and spread of infectious and mass non-infectious diseases (poisoning), public catering organizations are recommended to coordinate the range of dishes sold with the bodies exercising control and supervision functions in the field of ensuring the sanitary and epidemiological welfare of the population at the location of the public organization. nutrition.

(Revised edition, Rev. No. 2, No. 4)

8.3. Products are prepared in batches as they are demanded and sold.

8.4. Processing of raw and finished products is carried out separately in specially equipped workshops. In organizations that do not have a shop division, with a limited range of dishes produced, it is allowed to process raw materials and finished products in the same room on different tables.

(Changed edition, Rev. No. 2)

8.5. The meat is defrosted in two ways. Slow defrosting is carried out in a defroster at a temperature of 0 to 6 ° C, in the absence of a defroster - in meat shop on production tables. Meat in water or near the stove is not thawed. Re-freezing of defrosted meat is not allowed.

It is allowed to defrost meat in microwave ovens (installations) according to the modes indicated in their passports.

8.6. The meat in carcasses, halves and quarters is thoroughly cleaned before deboning, the brands are cut off, blood clots are removed, then washed with running water using a brush.

At the end of the work, the brushes are cleaned, washed with hot solutions of detergents at a temperature of 45 - 50 ° C, rinsed, soaked in a disinfectant solution for 10 - 15 minutes, rinsed with running water and dried.

8.7. Minced meat is stored for no more than 12 hours at a temperature of 2 to 4 °C. In the absence of cold, storage of minced meat is prohibited.

(Changed edition. Rev. No. 4)

8.8. By-products (brains, kidneys, scars) are defrosted in air or in water. Before heat treatment, brains, udders, kidneys, scars are soaked in cold water.

8.9. Poultry carcasses are thawed in air, then washed with running water and laid cut down to drain the water. Separate tables, cutting and production equipment are allocated for processing raw poultry.

8.10. The fish is thawed in air or in cold water with a temperature not exceeding 12 ° C at the rate of 2 liters per 1 kg of fish. To reduce the loss of minerals in water, it is recommended to add salt at the rate of 7-10 g per 1 liter. It is not recommended to defrost fish fillets, sturgeon fish in water.

8.11. Salads, vinaigrettes and sliced components in unseasoned form are stored at a temperature of 4 ± 2° From no more than 6 hours. Salads and vinaigrettes should be seasoned immediately before the holidays.

The storage conditions for salads with extended shelf life must comply with the requirements of the technical specifications for which the sanitary and epidemiological conclusion of the bodies and institutions of the State Sanitary and Epidemiological Service is issued in the prescribed manner.

Salads from fresh vegetables, fruits and greens are prepared in batches as needed.

(Changed edition. Rev. No. 4)

8.12. When preparing jelly, boiled meat products and other components are poured with strained broth and boiled again. Hot jelly is poured into pre-scalded molds (trays) and left to cool to a temperature of 25 ° C on production tables. Subsequent post-cooling and storage at a temperature of 4 ± 2 °C is carried out in a refrigerator in a cold shop. The sale of jelly without the presence of refrigeration equipment is not allowed.

8.13. The readiness of meat and poultry products is determined by the release of colorless juice at the puncture site and gray color on the cut of the product, as well as the temperature in the thickness of the product. For natural chopped products - not lower than 85 °С, for products from cutlet mass - not lower than 90 °С. The specified temperature is maintained for 5 minutes.

8.14. The readiness of products from minced fish and fish is determined by the formation of a crispy crust and easy separation of meat from the bone in portioned pieces.

Dishes containing fish, seafood or other products of animal origin in raw form must be produced in stationary catering establishments. Dishes are not subject to storage and must be prepared immediately before distribution by order of visitors.

(Changed edition. Rev. No. 4)

8.15. The preparation of culinary products in grills is carried out in accordance with the instructions for their operation, while the temperature in the thickness of the finished product must not be lower than 85 ° C.

Cooking in a microwave oven is carried out according to the attached instructions.

8.16. When frying deep-fried products, it is recommended to use specialized equipment that does not require additional addition of frying fats.

When using traditional technologies for the manufacture of deep-fried products, only specialized technological equipment is used. At the same time, it is carried out production control quality of frying fats.

Every day before and after frying, the quality of deep fat is checked for organoleptic indicators (taste, smell, color) and records are kept on the use of deep fat in accordance with Table. , , . In the presence of a sharp unpleasant odor; bitter, causing an unpleasant sensation of tickling aftertaste and significant darkening, further use of deep fat is not allowed.

Table 3

Grading scale for the quality of sunflower oil used as deep fat

| Importance factor | Number of points |

|||||

| Color (in transmitted and reflected light on a white background at 40 °C) | straw yellow | intense yellow | Intense yellow with brown tint | Light brown | Brown or dark brown |

|

| Taste (at 40°C and above) | No foreign taste | Mild bitter | Very bitter, causing an unpleasant tickling sensation |

|||

| Smell (at a temperature not lower than 50 °C) | No foreign odor | No characteristic sunflower oil, no foreign smell | Weakly expressed, unpleasant, products of thermal decomposition of oil | Pronounced, unpleasant, products of thermal decomposition of oil | Harsh, unpleasant, products of thermal breakdown of oil |

|

An example of calculating the average score:

(4 ´ 3 + 3 ´ 2 + 3 ´ 2)/7 = 3.4**) ,

where in the numerator:

4, 3, 3 - points for quality indicators,

3, 2, 2 - importance coefficients;

in the denominator:

7 - the sum of the coefficient of importance.

______________

* Calculate the average score, taking into account the coefficient of importance.

** If the fractional part is less than 0.5, then it is discarded; if 0.5 or more, it is rounded off.

Table 4

Rating scale for cooking oils used as deep fats

| Importance factor | Number of points |

|||||

| Color (in transmitted and reflected light on a white background at a temperature of 40 ° C and above) | White to light yellow | Yellow with brown tint | Light brown | Brown |

||

| Taste (at 40°C) | For cooking fats, frying, "Prima", "New" and vegetable fat without foreign flavors. For cooking fats "Ukrainian", "Belarusian", "Vostochny" - characteristic of the added fat, i.e., respectively, pork, beef or mutton without foreign aftertaste | Good, but off-flavour | Mild bitter | Bitter, with a pronounced foreign taste | Very bitter, causing a sensation of itching |

|

| Smell (at a temperature not lower than 50 ° C) | For cooking fats "Ukrainian", "Belarusian". "Vostochny", marguseline - characteristic of the added components, without foreign smell; for the rest - no foreign smell | With a slight foreign odor | Weakly expressed, unpleasant, products of thermal decomposition of fat | Pronounced, unpleasant, products of thermal decomposition of fat | Unpleasant, sharp, products of thermal decomposition of fat |

|

| Note: The average score is calculated using the importance factor. |

||||||

Registration N 20690

In accordance with federal law dated 03/30/1999 N 52-FZ "On the sanitary and epidemiological well-being of the population" (Collected Legislation of the Russian Federation, 1999, N 14, article 1650; 2002, N 1 (part 1), article 2; 2003, N 2, 167; 2003, N 27 (part 1), item 2700; 2004, N 35, item 3607; 2005, N 19, item 1752; 2006, N 1, item 10; 2006, N 52 ( part 1), art. 5498; 2007, N 1 (part 1), art. 21; 2007, N 1 (part 1), art. 29; 2007, N 27, art. 3213; 2007, N 46 , item 5554; 2007, N 49, item 6070; 2008, N 24, item 2801; 2008, N 29 (part 1), item 3418; 2008, N 30 (part 2), item 3616 ; 2008, N 44, item 4984; 2008, N 52 (part 1), item 6223; 2009, N 1, item 17; 2010, N 40, item 4969; 2011, N 1, item 6 ) and Decree of the Government of the Russian Federation of July 24, 2000 N 554 "On Approval of the Regulations on the State Sanitary and Epidemiological Service of the Russian Federation and the Regulations on State Sanitary and Epidemiological Rationing" (Collected Legislation of the Russian Federation, 2000, N 31, Art. 3295; 2004, No. 8, article 663; 2004, No. 47, article 4666; 2005, No. 39, article 3953) I decide:

Approve SP 2.3.6.2867-11 "Changes and additions No. 4 to the sanitary and epidemiological rules SP 2.3.6.1079-01 "Sanitary and epidemiological requirements for public catering organizations, the manufacture and turnover of food products and food raw materials in them", approved by the decision of the Chief State Sanitary Doctor of the Russian Federation, First Deputy Minister of Health of the Russian Federation dated November 8, 2001 N 31 (registered in the Ministry of Justice of Russia on December 7, 2001, registration number 3077), as amended and supplemented by the Decree of the Chief State Sanitary Doctor of the Russian Federation, First Deputy Minister of Health of the Russian Federation dated 04/03/2003 N 28 "On the approval of SP 2.3.6.1254-03 - Addition N 1 to SP 2.3.6.1079-01 (registered in the Ministry of Justice of Russia on 04/23/2003, registration number 4447), by a resolution of the Chief State Sanitary Doctor of the Russian Federation dated 03.05 .2007 N 25 "On approval of SP 2.3.6.2202-07 - Amendments N 2 to SP 2.3.6.1079-01" (registered in the Ministry of Justice of Russia on 06/07/2007, registration number 9614); Decree of the Chief State Sanitary Doctor of the Russian Federation dated December 29, 2010 N 187 "On approval of SP 2.3.6.2820-10 Addendum N 3 to SP 2.3.6.1079-01 (registered with the Ministry of Justice of Russia on 17.03.2011, registration number 20156) (Appendix).

G. Onishchenko

Application

Amendments and additions No. 4 to SP 2.3.6.1079-01 Sanitary and epidemiological requirements for public catering organizations, production and turnover of food products and food raw materials in them

Sanitary and epidemiological rules SP 2.3.6.2867-11

Make the following changes and additions to SP 2.3.6.1079-01:

1. Clause 1.2. add the following paragraph to the second paragraph:

"These sanitary rules are mandatory for all citizens, legal entities and individual entrepreneurs whose activities are related to the organization of catering for the population, including during mass public events (fairs, sports competitions, olympiads, university games, cultural and entertainment rallies and other similar public events).

2. In paragraph 2.2. After the first paragraph, add the following paragraph:

"When placing public catering organizations in attached, built-in and attached to residential and public buildings, in non-residential floors of residential buildings, in public buildings, hygienic standards for noise levels, infrasound, vibration, electromagnetic fields in the premises of residential, public buildings and on the territory of residential buildings, as well as maximum permissible concentrations and approximate safe levels of exposure to pollutants in the atmospheric air of populated areas.

3. In clause 2.2. delete the third paragraph.

4. In paragraph 2.2. in the fourth paragraph of paragraph 2.2. after the words "to have entrances" delete the words "and emergency exits".

5. Clause 4.11. add the following paragraph to the second paragraph:

"It is allowed to cook dishes on the grill in public catering establishments located in separate buildings, subject to the use of modern equipment."

6. Clause 5.2. add the following paragraph to the second paragraph:

"For the temporary storage of ready-made meals before their sale, catering establishments should provide premises equipped with refrigerators and racks."

7. Clause 5.9. put in the editorial:

"In the shops for the preparation of cold dishes, soft ice cream, in the confectionery shops for the preparation of cream and finishing cakes and pastries, in the shops and areas for portioning ready meals, packaging and forming sets of ready meals, bactericidal lamps are installed, which are used in accordance with the instructions for exploitation."

8. Section V of these sanitary rules shall be supplemented with paragraph 5.16. the following content:

"5.16. In public catering organizations, cosmetic repairs (whitewashing and painting of premises, preventive maintenance of sanitary and technological equipment) should be carried out as necessary and its painting."

9. Clause 6.1. add the following paragraph to the second paragraph:

"When catering for participants in mass public events, a sufficient amount of dishes should be provided. When a catering organization provides catering services (cooking and delivering them to the place of order, heating dishes, setting the table, cleaning dishes, premises and territory, carried out by field service personnel) the number of tableware and cutlery is completed in accordance with the number of servings for a single use. The supply of clean wine glasses and cups is calculated for 2-3 drinks by visitors."

10. Clause 6.3. add the following paragraph to the second paragraph:

"For grinding raw and heat-treated food products, as well as for raw semi-finished products and culinary semi-finished products of a high degree of readiness, separate technological equipment must be provided and used, and in universal machines - replaceable mechanisms."

11. Clause 6.5. add the third paragraph with the following content:

"Cutting equipment may be color-coded along with letter markings in accordance with the product processed on them. Cutting equipment for finished and raw products must be stored separately."

12. Clause 8.1. add the following paragraph to the second paragraph:

"Cooking, culinary and confectionery products is carried out by catering personnel with hygienic training. It is not recommended to involve personnel for the simultaneous implementation of work within the framework of various food processing technological processes."

13. Clause 8.2. add the following paragraphs:

"The production of products must be carried out according to the technical documentation developed in accordance with the procedure established by law.

When holding mass public events, in order to prevent the occurrence and spread of infectious and mass non-infectious diseases (poisoning), public catering organizations are recommended to coordinate the range of dishes sold with the bodies exercising control and supervision functions in the field of ensuring the sanitary and epidemiological welfare of the population at the location of the public organization. nutrition."

14. In paragraph 8.7. the words "no more than 6 hours" shall be replaced by "no more than 12 hours".

15. In paragraph 8.11. in the first paragraph, after the words "vinaigrettes" add "and chopped components"

16. Clause 8.14. add the following paragraph to the second paragraph:

17. In paragraph 8.25. the words "If there is a sanitary and epidemiological conclusion of the bodies and institutions of the State Sanitary and Epidemiological Service" shall be replaced by "Subject to compliance with the requirements of these sanitary rules", hereinafter.

18. In the first paragraph of clause 8.26. delete the words "and the presence of a sanitary-epidemiological conclusion of the bodies and institutions of the State Sanitary and Epidemiological Service"

19. Clause 8.26. add the eighth paragraph as follows:

"- placement of the pavilion at a distance of no closer than 50 meters from residential buildings, medical and preventive organizations, sports and recreational and educational institutions."

20. In paragraph 8.27. the words "in the presence of a sanitary-epidemiological conclusion of the bodies and institutions of the State Sanitary and Epidemiological Service" shall be replaced by "subject to compliance with the requirements of these sanitary rules."

21. Clause 9.3. add the second and third paragraphs as follows:

"It is not allowed to dress salad products, first and second courses with sauces, intended for sale outside a public catering organization. Sauces for dishes are delivered in individual consumer packaging.

Dishes that have undergone heat treatment and are intended for temporary storage prior to their sale must be subjected to rapid cooling from a temperature of +65 ° C to +5 ° C for 1 hour in a special quick cooling refrigerator. Portioning of ready meals, cold appetizers should be carried out in a room with an air temperature not higher than +16 ° C on tables with a cooled work surface.

22. Clause 9.7. add the second, third and fourth paragraphs as follows:

"Public catering products in the form of semi-finished products, chilled, frozen and hot dishes, culinary products, sold outside the public catering organization on consumer orders and in trade organizations and culinary departments, are packaged in consumer disposable packaging made from materials approved for contact with food products. .

Serving and portioning of dishes must be carried out by staff using disposable gloves for every type of food.

When carrying out catering services (or catering on the orders of consumers outside a public catering organization), opening consumer packages with food, drinks, dishes, as well as portioning dishes, preparing culinary products for distribution is carried out in a dedicated separate room located directly at the venue of the event. .

23. Clause 9.9. add the second, third, fourth and fifth paragraphs as follows:

"The temperature of the dishes during their distribution must meet the requirements established in clause 9.2. of these sanitary rules.

Each container with food products (dishes, culinary products) must have a marking label indicating its name and address of the manufacturer, date and hour of manufacture, storage conditions and expiration dates.

For catering, picking containers and trolleys food products starts no earlier than 3 hours before the start of the event.

Each order is registered in accounting documentation indicating the name of the dish, date and hour of manufacture.

24. In the first paragraph of clause 9.10. delete the words "coordinated with the bodies and institutions of the State Sanitary and Epidemiological Service in the prescribed manner"

25. In paragraph 9.10. delete the second paragraph.

26. Clause 9.10. add the third paragraph with the following content:

"The sale of semi-finished products, ready-made meals and other products outside the catering organization should be carried out in the presence of accompanying documents (consignment note, certificate of quality and safety, declaration or certificate of conformity). Accompanying documents in a public catering organization must be stored for at least 30 days from the date of manufacture of the dish.

27. Clause 9.11. add the following paragraph to the second paragraph:

"Delivery of ready-made meals for serving a public event should be made in tightly closed containers, boxes, thermal containers, cooler bags and other similar containers provided with a marking label. The labels are stored until the end of the service of the event"

28. Clause 9.13. add the fourth paragraph as follows:

"Food products produced in public catering organizations, the expiration date of which has expired, are subject to disposal or destruction in the prescribed manner."

29. Clause 13.4. add the tenth paragraph as follows:

"For additional processing of hands, the use of skin antiseptics is possible."

30. In paragraph 13.5. after the words "for the presence of pustular diseases" add ", as well as for workers involved in the preparation, portioning and serving of dishes, their distribution." Further in the text.

31. Clause 14.3. add the following paragraph to the second paragraph:

"During the period of mass public events, catering organizations involved in catering are recommended to provide additional control over the quality and safety of prepared dishes. Daily samples are taken to control prepared dishes.

The daily sample from the prepared dish is taken with sterile (or boiled) spoons into labeled sterile (or boiled) glassware with tightly closed glass or metal lids. Portion dishes are selected in full, while salads, first and third courses, side dishes - at least 100 gr.

The selected daily samples are stored for at least 48 hours in a special refrigerator or in a specially designated place of the refrigerator at a temperature of +2- +6 ° C.

32. Clause 16.1. add the following paragraph to the second paragraph:

"Temporary quick service public catering organizations are provided with food products (semi-finished products, dishes, culinary and other products) prepared in stationary public catering organizations.

33. In paragraph 16.4. after the words "products from semi-finished products of a high degree of readiness" to add "in a consumer package that provides heat treatment food product."

34. Clause 16.4. add the following paragraph to the second paragraph:

"Temporary fast food catering organizations, remote from stationary catering organizations, must be equipped with refrigeration equipment for storing perishable food products, drinks, ice cream."

SanPiN 2.3 6.1079 01 was put into effect by the Decree of the Glavsanvracha of the Russian Federation dated November 8, 2001 No. 31 and regulated the regulatory requirements for the activities of organizations providing catering services.

The purpose of the adoption of these rules is indicated in clause 1.1 - preventive measures aimed at preventing the occurrence and spread of infectious and non-infectious poisoning among citizens.

Let's take a closer look sanitary requirements for catering establishments and the like.

Since its approval, SanPiN of public catering enterprises has been repeatedly supplemented with new rules. Recent amendments to the specified normative document were submitted in June 2016.

Since its approval, SanPiN of public catering enterprises has been repeatedly supplemented with new rules. Recent amendments to the specified normative document were submitted in June 2016.

SanPiN 1079 01, as amended for 2016-2017, defines the conditions for the process of operation of public catering enterprises, regardless of their organizational and legal form. At the same time, the regulations apply not only to existing catering outlets, but also to newly built and reconstructed facilities.

Certain types of activities of these organizations subject to rationing according to the specified SanPiN include:

- production process for the manufacture of food products;

- the procedure for receiving raw materials intended for the manufacture of food and beverages;

- processing of the obtained raw materials into the finished product;

- storage of raw materials and prepared foodstuffs.

Monitoring compliance with SanPin standards is carried out by authorized bodies, including the service of Rospotrebnadzor, which has the right to conduct scheduled and unscheduled inspections of the activities of catering enterprises.

The standards enshrined in SanPin are classified according to the following parameters:

The standards enshrined in SanPin are classified according to the following parameters:

- basic factors production process, including hygienic standards for noise, vibration and infrasound levels;

- requirements for equipment and operation of water supply and sanitation systems;

- standards for the microclimate of the premises of public catering outlets, including the levels of permissible concentration of hazardous substances in the air;

- storage requirements for raw materials and finished food products;

- standards for cleaning and disinfection of industrial premises.

For each of these parameters, specific indicators and standards are indicated, which are to be expressed in a numerical value. Their control measurements make it possible to identify the facts of violation of the SanPin, which entails the application of liability measures, up to the suspension of the organization's activities.

Download SanPiN 1079 01

SanPiN public catering 2016 regulates in detail the standards production factors during the operation of catering outlets. Their observance, first of all, should be ensured by compliance with architectural and planning requirements.

SanPiN public catering 2016 regulates in detail the standards production factors during the operation of catering outlets. Their observance, first of all, should be ensured by compliance with architectural and planning requirements.

Architectural planning should include the following requirements:

- compliance with the norms and rules established by building regulations, standards of architectural and planning activities, SNiP, GOST, etc.;

- compliance with general and particular regulations of the production process;

- compliance with the legislation in the field of ensuring the sanitary well-being of citizens;

- observance of hygienic norms of the maximum permissible level of noise, infrasound and vibration.

These requirements must be observed already at the design stage of production facilities. In particular, the application of SanPiN food production prohibits the arrangement of premises for citizens to live in production facilities, as well as the admission to production workshops of unauthorized persons not related to the production of food products.

SanPiN for catering 2016 contains standards for arranging industrial premises with their own water supply and sewerage systems connected to a common external engineering network. These rules are due to the requirement to observe the personal hygiene of staff and customers of public catering outlets.