- Modular pictures

- Implementation of modular paintings

- wooden pallets

- Chipboard coffins

- garden figures

- Reinforced concrete rings

- Polyurethane molds

- Cakes to order

- Houses - shelves

- Pillows for pregnant women

- Step by step opening plan

- What documents are needed to open

- Taxation system

- Permissions to open

We bring to your attention ten best business ideas for mini production, which can be organized in a small workshop or garage. Most of the items below can be made by one or two people.

Modular pictures

Modular pictures - fashion trend in decorating home and office interiors. This product is in good demand and is purchased both as a gift and simply for wall decoration (for example, for a family photo).

Technology for the production of modular paintings

Modular paintings are made from stretchers and fabric on which the image is applied. The production technology is not complicated and anyone can master it. Ready-made stretchers are purchased from private wood craftsmen (or purchased in stores), and the image is printed on fabric using a conventional plotter.

Implementation of modular paintings

Modular paintings are implemented through individual orders, specialized stores and hypermarkets, as well as in the format of live advertising (on busy streets). The retail price for modular paintings starts from 4 thousand rubles. Not a complicated business that is organized in a small workshop. Read more…

- Business plan for the production of modular paintings (19 sheets) - DOWNLOAD ⬇

wooden pallets

wooden pallet- a highly demanded product in logistics. Almost every industrial and commercial enterprise that sells products in large quantities needs pallets, which greatly facilitate the loading and unloading of goods.

Pallet production technology

On a small "garage" scale, pallets are made by hand, using a pneumatic hammer. The main difficulty is to produce those very thin boards that form the frame of the product. For cutting such boards, special multi-saw frame machines are used (for example, RM-50). The average price is 500,000 rubles. The approximate cost of one wooden pallet is 120 rubles, while the retail one is at least 200 rubles. "Navar" from 80 rubles. from one pallet. The production of 100 pallets per day will bring about 8,000 rubles. How to quickly make a pallet:

Professional business plans on the topic:

- Production business plan wooden pallets(14 sheets) - DOWNLOAD ⬇

Chipboard coffins

We can say a 100% option is the business idea of producing coffins from chipboard (or other cheap materials). funeral services always in demand, regardless of the crisis. Expensive coffins may not go, but budget (economy) in a crisis will be bought up only in this way. Chipboard is used as the frame of an economy coffin, and sheathed with velvet or fabric. The cost of producing a unit of output is 2 - 3 thousand rubles. This option costs the customer 4-6 thousand rubles.

Professional business plans on the topic:

- Coffin production business plan (18 sheets) - DOWNLOAD ⬇

garden figures

In the spring and summer, garden figures are in good demand for decorating household and summer cottages. The manufacturing technology of such products is extremely simple and comes down to pouring a pre-prepared mixture into a finished mold. After the figure dries, it remains only to paint it with a spray gun. The only difficulty in this case is to buy those very forms that are not cheap.

They make garden figures from gypsum (a cheaper option), concrete or polyresin. The most common sales methods are: deliveries to large construction and hypermarkets, as well as sales near highways with a large flow of cars. The profitability of the business in the production of garden figures is estimated at 35%. Read more…

Professional business plans on the topic:

- Business plan for the production of plaster figures (14 sheets) - DOWNLOAD ⬇

Reinforced concrete rings

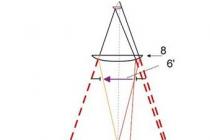

A good idea for a small business is the production of reinforced concrete rings. This product is extremely in demand in the construction of wells, ventilation shafts and bridges. In view of the fact that the rings are quite heavy and their delivery is extremely expensive, there are not so many large manufacturers of these products. This means that there is no huge competition and pressure from federal players. This is one of the best products for small production.

What appeals to this idea is a relatively inexpensive start and understandable technology. The minimum set of equipment, including a concrete mixer, a vibrating mold and a vibrating sieve, will cost about 150,000 rubles. This entire "line" can fit in an open area of 100 - 200 square meters. m. The main thing is to choose a flat horizontal surface. The main raw materials for the manufacture of reinforced concrete rings are: reinforcing cage, cement, crushed stone, sand and plasticizing additives. A sewer reinforced concrete ring with a diameter of 1 m at a cost of 800 - 1300 rubles. The minimum selling price is 2000 rubles. The margin is about 100%! Read more…

Professional business plans on the topic:

- Business plan for the production of reinforced concrete rings (11 sheets) - DOWNLOAD ⬇

Polyurethane molds

One of the most suitable ideas for mini home production is the production of silicone or polyurethane molds. Such forms are most often used for the production of decorative stone. The technology is quite simple, and from the equipment, only the “hands” of the master are mainly required. To begin with, a sample is bought, according to which the future matrix (form) will be produced. It is easier for everyone to copy samples from natural stone. The first thing they start with is cutting a sample of stone thin layer and stick on a flat surface. Then formwork is created for pouring polyurethane. Joints are sealed. After the master model is ready, a release agent is applied to the surface of the model. Next, the polyurethane mixture is prepared. The most popular version is Ecarast RT 45A polyurethane. The resulting mixture is poured into the model and incubated for 4 - 5 hours. The form is ready!

The retail price of a silicone mold starts from 1800 rubles. Markup not less than 100%. You can (and should) sell these products online. So, according to Wordstat (Yandex statistics), the phrase “buy a mold for stone production” is searched for about 9,000 times a month! At the same time, there is practically no competition. How the silicone mold is made is clearly shown in the following video:

Professional business plans on the topic:

- Silicone mold production business plan (13 sheets) - DOWNLOAD ⬇

Cakes to order

A tried-and-true idea for mini-home production is to make custom cakes. The idea is the best for lovers of home baking.

With the advent of social networks, advertising such a business has become much easier. Colorful cakes, some of which cost more than 6000 rubles. (Moscow, St. Petersburg), laid out in photo albums that are viewed potential clients. Such cakes are most often ordered for birthdays, anniversaries, weddings and corporate events. It should be taken into account that cake making order is seasonal. Most of the bookings are made in the spring, while in the summer there is silence, as people go on vacation. Profitability this business estimated at 70%.

Houses - shelves

Extremely fashionable in Lately decoration of children's rooms with shelves is considered. This mini-furniture combines two useful functions at once. Firstly, this thing looks cool, and secondly, you can put toys, flowers, various trifles, etc. on it. At the same time, the house-shelf can not only be placed on the floor, but also hung on the wall. So it won't take up any space at all.

In general, the product is in high demand, it is ordered on the Internet and bought in furniture stores. Production of houses - shelves - a great option for a small family business, which can be organized in fact in "garage conditions".

Shelf house production technology

Materials for the house can be bought, so to speak, ready-made. That is, you take ready-made wardrobe shelves, horizontal shelves, 10x3 cm boards, wood glue, nails, etc., cut the boards to the required sizes and assemble the structure. If you fork out for machines and produce a cabinet-shelf yourself, then the income will be even higher, since material costs are reduced. A house measuring 600 * 400 mm will cost at least 3000 rubles. (prices can be viewed online). While the cost of material is no more than 1000 r. "Navar" consider yourself. The main condition for the success of such a business is the presence of good craftsmen. In principle, even beginners can assemble a house-shelf. In the following video, an ordinary housewife assembles a similar design:

Pillows for pregnant women

A pregnancy pillow is a specific product that is bought, as the name implies, only for a specific occasion. But that doesn't make it low cost. On the contrary, the markup on pillows for pregnant women is several times higher than on classic options. So, the price of an ordinary pillow made of artificial filler is on average 500 rubles, while for pregnant women it is at least 1100 rubles. At the same time, the material and filler are, in fact, the same.

Pillows for pregnant women differ from ordinary pillows in their unusual design, which can take the form of a horseshoe or bagel to support the head and abdomen. The main purpose of such pillows is to adapt to the human body as conveniently as possible and provide comfort during rest. For a small manufacturer this product It is interesting in that, unlike ordinary pillows, it is very often bought on the Internet. Therefore, sales are much less of a problem. Can make a small website to advertise in in social networks, on Avito, etc. There are many options in the "offline". For example, donate products to specialized stores for expectant mothers. The pillow production workshop can carry out a prefabricated function for the most part. That is, you buy pillowcases from TIK fabric or microfiber, cut them to the required sizes, and make covers from cotton, coarse calico, satin. As a filler, you can use holofiber or artificial swan down.

The article will teach you how to sell products over the Internet:

How to make money on Avito - tips and types of earnings.

Professional business plans on the topic:

- Business plan for the production of pillows for pregnant women (11 sheets) - DOWNLOAD ⬇

Metal stoves "potbelly stoves"

Demanded goods for private houses and baths are metal stoves. A variety of fireplaces, potbelly stoves are even installed in garages. Not infrequently, such furnaces require an individual approach (each client needs his own dimensions and gadgets). Therefore, in addition to generally accepted standards, it is possible to produce furnaces to order.

One person can build a small oven in a mini-workshop. From the materials you will need sheets of metal, pipes, and from the tools - a welding machine, a protective mask, a hammer, a set of electrodes and a grinder. Earnings from one part sold will largely depend on the high cost of the purchased material. Well, and the trade margin, respectively. So, the production of an elementary sauna stove can take 3,000 - 6,000 rubles, while it can be sold at a price of 10,000 rubles.

Step by step opening plan

- 1. Register an enterprise.

- Rent or buy premises for production.

- Purchase materials and equipment needed for production.

- Hire employees.

- Engage in the sale of manufactured products.

How much money can you make from small businesses

It all depends on the type of mini-business:

- If this is the production of modular paintings, then the sale of one painting is from 4,000 rubles.

- 2. The cost of production of 1 pallet is 120 rubles, and it can be sold for 200 rubles.

- The profitability of the production of coffins from chipboard is 100%.

- The profitability of gypsum garden figures is 35%.

- The production of a reinforced concrete ring will cost 800-1,300 rubles, it can be sold for 2,000 rubles.

- The margin for the production of polyurethane molds is 100%.

- Profitability of cakes to order -70%.

- The production of houses - shelves will cost 1,000 rubles, and they can be sold at a price of 3,000 rubles.

- The cost of pillows for pregnant women is 2 times higher than regular ones.

- 3,000-6,000 rubles will be spent on the production of a metal stove - a potbelly stove, and it can be sold for 10,000 rubles.

How much money do you need to start a business.

Again, it all depends on the type of mini-production. For some types of mini-business, you can not rent a room, but use your garage or a room in the private sector, and the production of custom-made cakes can be set up at home. For others, it is necessary to rent a production workshop. In some types of business it is necessary to use hired labor, and costs will increase accordingly. If you want to make good money and you have initial capital for investment, see course catalog who will help you understand the intricacies of investing and offer you ready-made solutions.

Which OKVED to indicate for the purpose of registration

OKVED 2 16.24 - production of wooden containers. OKVED 20.75 Manufacture of other fabricated metal products. OKVED 26.66 Manufacture of other products made of concrete, plaster, cement. OKVED 2 13.92 Manufacture of finished textile products, except clothing. OKVED 10.72.2 production of long-term storage cakes and pastries.

1. Mini Brick Making Plant - Yufeng DMYF500

Country of origin - China, JUNAN YUFENG MOLD FACTORY. New factory DMYF500 (pictured above) with a capacity of 800-900 bricks per eight-hour shift will cost you $9,000. Used version can be found for 6-7 thousand dollars. The weight of the line is 2500 kg, cement and water are used as raw materials. Clay can also be used as a raw material.

For the manufacture of a thousand units, approximately 775 kg of cement and 300 liters of water will be required.

Producing 27,000 bricks per month, the company earns about $8,300 in wholesale, A net profit will be approximately $4,000 per month.

A ready-made mini-factory with an output of 10,000 units per hour will already cost $ 19,000. But the profit from it starts at $ 10,000 per month. Example is JZK40/40-3.0 from Yingfeng Machinery Co., Ltd.

2. Mini-plant for the production of concrete - RBU-1G-10B

Inexpensive machines like this one are produced in Russia on the basis of ZZBO LLC. This model is designed to produce 10 cubic meters of concrete per hour and costs $11,000. Power - 10.5 kW. Suitable for concrete tapping various types(silicate, gypsum, cement, polymer cement), this is important for expanding the sales market.

Mini plants for the production of concrete require premises with an area of 250-300 square meters. Such an enterprise is best opened on the outskirts of the city or even outside the city. The main thing is to provide access to the building of trucks for the shipment of raw materials (cement compositions, gypsum, lime, etc.) and finished products for sale.

The industrial workshop produces 2300-2400 cubic meters per month. m of concrete costing $35-40 per cubic meter. The cost of one cubic meter of production is about $21-22. After deducting the rent, utilities and wages, we get a net profit in the region of 30-32 thousand dollars per month.

3. Microbrewery - BlonderBeer 300 L

Optimal equipment for small businesses from the Slovak company Techimpex. Produces 300 liters of beer per day (restaurant-type brewery), the maximum number of varieties is 4-5. This size is suitable small firm supplying the product to cafes and shops draft beer. Ideally, you can open your own brewery shop and sell beer at the market, and not wholesale price. The cost of the line is around $ 10,000.

Nuances of the organization

In addition to a set of equipment, you will need to separately purchase fermentation tanks (tskt - a cylindrical-conical tank), since aging and fermentation last 10-25 days. In order to maintain the required production volumes on a daily basis, you will have to spend money on purchasing 10-15 ckt per 200 liters (costs - from $ 8,000).

The revenue of the microbrewery reaches $7000 per month, net profit is $3500-4000.

Other profitable options

Where else can you buy a mini-brewery at a good price? ZIP Technologies Ltd (Hungary), Impiantinox S.r.l (Italy), Miass Machine-Building Plant (Russia), BeerFactory (an importer of Chinese brands).

From China really order a more productive device at a good price. For example, a line from GEONETconsult Ltd producing 150 liters per hour (1200 liters per day) will cost around $20,000.

4. Mini toilet paper mill - XY-TQ-1575B

This equipment is for the production toilet paper full cycle with a speed of 150-200 meters of paper per minute of the Chinese brand China-line. Price - $ 16,000. The kit includes raw material tray, paper transfer rollers, embossing unit, perforation, block rolling, cutting and packaging machines. Power - up to 10 kW. Dimensions - 6.2X2.75X1.8 m.

For such a line, a room of about 150 square meters is required. m with sewerage and exhaust. Water consumption - from 3 cubic meters per day. The raw material is waste paper. Thanks to this, the idea of producing toilet paper is equated with socially significant projects, and the entrepreneur can count on subsidies from the state.

One ton of raw materials allows you to get up to 9 thousand rolls of finished products. The rate of processing of raw materials is 1-2 tons per day.

In a month, selling toilet paper really earns from $ 10,000.

5. Mini feed mill - 9FH-500

For the manufacture of animal feed, Chinese mini-factories for small businesses are best suited. For example, a 9FH-500 machine from supplier Argentum Amur will cost just $2,000. Its productivity is 1500 kg of feed per hour, power is 4-7.5 kW. Weight - 370 kg, and dimensions - 1.44x1.04x2.3 m. This will allow you to install the machine in a small room (70-80 sq. M, along with a warehouse of raw materials, products and utility rooms), saving on rent. Heating is not required for such a plant.

9FH-500 is suitable for crushing feed grains (rye, corn, wheat, barley, etc.) and processing sawdust, bran, husk, straw, hay. As a result, we get a complete feed for birds and livestock.

Such a machine produces 350 tons of compound feed per month and allows receive from 9000 $ net income.

6. Mini-plant for the production of gas silicate blocks - "Premium Brick Plus"

This is the official importer of Chinese machine tools - brand LINYI WANTE MACHINERY. The power of the line is 250 kW. Productivity - 50,000-70,000 cubic meters. m per year. Such a mini plant for the business of producing gas silicate blocks will cost 13 thousand dollars. The required area of \u200b\u200bthe production workshop is 3000 square meters. m. Therefore, it is worth placing outside the city in order to reduce rental costs. Net profit - from $ 6,000.

7. Mini-factory for the production of canned fish - NPO "MINIPLANT"

A line from a Russian manufacturer, including a cutting machine, a dispenser and a device for sealing canned food. The price of such a complete set is around 11 thousand dollars. It produces 800 cans per hour and requires an area of about 90 square meters for the workshop itself. Serving such a machine should be 2-3 workers.

Even this will allow to produce approximately 192,000 cans per month. It is profitable for a small enterprise to produce a product in the middle price segment: these are tomato sprats, sardines in oil, sprats. Monthly net profit - from 10 thousand dollars.

8. Mini Textile Factory - Hengyu Hja-610

For the manufacture of textiles, even in small volumes, you will need serious equipment, the cost this machine 16000 & supplier from China. Power - 4.5 kW, dimensions: 4.1 × 2.1 × 2.5 meters. Productivity - about 50 meters of fabric per day. It is profitable to make linen, cotton, knitted fabrics. You can earn about 6-7 thousand dollars a month on textiles.

9. Mini-factory for the production of milk and dairy products - GEONETconsult

This is produced in Korea and China, it can be purchased through sales offices in Russia. The cost of a set with a capacity of 300 liters per hour is $ 22,000. With its help, milk is processed for the manufacture of kefir, sour cream, yogurt, cottage cheese. Power - 39 kW.

For a small enterprise, Kolax mobile dairies are perfect, the output is from 500 liters per day. The cost is from $ 13,000. Modular complexes are fully equipped and consist of ready-made workshops-modules, they also provide areas for warehouses, bathrooms, utility rooms.

How much can you earn from milk processing? Monthly revenue - about 30 thousand dollars, net income - about 14,000-15,000 dollars.

10. Paper & Wet Tissue Mini Plant - A419 LYHIA Model WN-C840

The country of origin is China. Such machines for small businesses give out about 3000 pieces / min, their price is in the region of 20 thousand dollars. The advantage of this equipment is that it produces dry and wet self-stretching wipes. This significantly expands the market. Power - 20 kW, dimensions - 4.5x1.9x1.85 meters, weight 2300 kg. An area of 20 square meters is enough for an industrial workshop, the rest of the space is allocated for a warehouse and utility rooms.

The set includes machines for unwinding the paper base, embossing, cutting, folding, packing and packaging of finished products.

By producing 40 million wipes per month (or 400,000 packages), you get about $ 60,000, a net profit of about 30 thousand.

The nuances of small business in the industrial sector

The cheapest way is to order mini factories for small businesses from China. When purchasing equipment abroad, you can contact intermediary firms that will take over the process of paperwork, delivery and installation.

By the time of purchase, you should have an industrial workshop ready, the necessary communications have been connected. The average cost of commissioning for mini-factories is $1500-2000. Purchase machines with a warranty period of one or two years or more.

How you can save money on shopping:

- Buy used machines cheaper by 20-25%;

- Search various companies for new items recently launched on sale. The first batch may be cheaper. Or, on the contrary, you can stumble upon a sale of equipment of an older modification.

It is beneficial to open a small production if you have found potential buyers in advance.

For example, concrete-mixing plant can offer a product construction firms in their city (in the absence of competition, it is cheaper for them than ordering in another city).

In the presence of a large number wholesale warehouses, essential goods, etc. Planning should start with a search for sales markets, if you find a niche without local competitors, you can get high and stable profits.

- (185)

- (102)

It would seem that the plant is an unbearable idea for a small business. The word "factory" is associated with huge workshops, bulky machines, hundreds of people production staff. Such giants, built, for the most part, during the Soviet Union, in dynamic market conditions often turn out to be unprofitable - such a farm is not easy to maintain, and modernization requires decent cash injections.

In many industries, mini-factories can compete well with them. Organize own production using them is possible even for a novice entrepreneur. A mini-factory is like a miniature factory, but it has a number of undeniable advantages.

Benefits of compact manufacturing units

- Mobility. The production complex is quite simple to assemble and occupies a small space, so it can be located on a rented area and, if necessary, “move” to another place.

- Profitability. You save not only on the price of equipment, but also on wages - a mini-factory does not require a highly skilled work force(This paragraph does not apply to repair and maintenance work).

- High efficiency. It is achieved by using technologies and resources that are different from those used in our usual enterprises.

- Environmental friendliness. Technologies for the processing of industrial and household waste and the use of recycled materials are actively used. An important item that can be used for marketing purposes.

- Possibility of exclusive production. The exclusive is gaining more and more popularity, and the price for it is much higher than for mass-produced goods.

Those who are going to purchase socially significant equipment can count on government assistance to small businesses. It is possible to receive subsidies from the state for those who will be engaged in waste processing and improve the ecological condition of the local territory.

Buying a set of equipment will be a good option for starting a business in a small town.

Some of the entrepreneurs who have their own mini-factory started a business in a garage - /otkryt-biznes/idei/proizvodstvo/v-garazhe.html

What mini-factories for small businesses are

The growing variety of mini-factories for small businesses can be roughly divided into industries:

The range is not limited to the above list, it only reflects the most popular in terms of investment and payback. If you wish, you can purchase, for example, a woodworking complex or a plant for the production of hardware products - the choice of such complexes on the market is now very large.

In the selection process, the entrepreneur faces the question - what equipment has the best price-quality ratio?

Ten years ago, in Russia, preference was given to Western-made machinery and equipment, mostly second-hand. Currently, small businesses are increasingly trusting Chinese manufacturers - the quality of their products is constantly growing, and prices remain quite reasonable.

Overview of popular equipment kits from China

Among domestic entrepreneurs, the following mini-factories from China are popular:

- For the production of bricks. Clay or waste from other industries (metallurgical, mining, etc.), Portland cement and water are used as the main raw materials. If necessary, pigment is used for coloring, and sawdust is required for the manufacture of hollow bricks.

- Mini Milk Processing Plant is able to process from 300 to 20,000 kg of milk per day: cow, goat, camel, mare. With the help of such a complex, it is possible to pour milk into packaging and receive different kinds dairy and sour-milk products: kefir, yogurt, butter, cheeses, koumiss, etc.

- For the production of foam blocks. In this case, there is no need to use high technology, the manufacture of foam blocks is quite cheap. Great option for entrepreneurs developing or planning to start Building bussiness, because You can organize the production of foam blocks using a mini-factory right on the construction site. At the same time, you not only save on building materials, but also independently control the quality of products. Such a plant pays off quickly enough.

- For waste processing. Will require obtaining a license for waste processing, as well as permission from the fire and sanitation services. The advantage of such a plant is that it environmental significance can help with obtaining, for example, a grant for a small business. Similar programs for entrepreneurs are held in many regions of the country.

- Compound feed mini-factory. It will be of particular interest to farmers interested in developing their own economy and reducing the cost of purchasing and delivering animal feed. Focused on the following products:

- complete feed for animals or poultry;

- feed concentrates;

- balancing feed additives.

- Production of toilet paper. Waste paper is used as raw material, which gives this process socially significant orientation. An entrepreneur can receive tax breaks and subsidies from the government. In addition, such products will always be in demand, which means that with proper organization business with sales will not be a problem.

Price

The price of the production complex consists of the cost of the equipment itself, the cost of delivery, customs clearance and other documentation, plus taxes and trade margin.

In order not to overpay, it is recommended to carefully study all offers and weigh all costs, because. the cost varies considerably. To a greater extent, the price depends on the completeness of the plant, the quantity and productivity of the equipment.

For example, a mini-factory from China for the production of standard porous bricks, with a capacity of 10,000 units of standard bricks for an 8-hour shift, will cost 20-25 thousand dollars. And a complex that produces 10 times more products per shift and is able to produce more paving slabs, will cost about $130,000.

Prices for modules for the production of foam concrete and foam blocks start from 100,000 and reach up to 2 million rubles. For quite low price you can buy such a concrete mini plant of Russian production.

The cost of complexes for the production and processing food products also differ significantly. Having at your disposal an amount of 1 million rubles, you can organize the issue ( we are talking about mini-factories with relatively small productivity):

- mayonnaise, ketchup, other sauces,

- fish preserves,

- juices, nectars, purees,

- pizza,

- dried mushrooms,

- pickles and marinades;

- crispy potatoes and chips,

- vegetable oil, etc.

Milk and meat processing lines will cost much more - the price starts from 2 million rubles and reaches 20-30 million rubles.

For a relatively small amount - about 500,000 rubles. you can buy a canning mini-factory or a small brewery.

Prices for mini-factories for waste processing depend on the type of raw materials used. Tire recycling module crumb rubber can be bought for 1.5 million rubles, and for the processing of PET and PVC waste it will cost about 10 million rubles. And again, it all depends on the quantity and performance of the equipment. You can choose to buy kits for small production via the Internet, since there are many offers today. You can purchase domestic or imported equipment.

When ordering from abroad, it will be more convenient to make a purchase through an intermediary company, which will take care of the delivery and paperwork, and, if necessary, will carry out installation. Of course, the provision of such services will increase the purchase price, but will significantly save your time and nerves.

Before purchasing equipment, monitor the market for the product you want to manufacture, there may be several areas to consider. Do not be too lazy to study in detail the offers of various companies for the sale of industrial complexes, compare prices and conditions.

Try to take into account all costs as much as possible and do not save on the quality of equipment. And then your mini-factory will not only make a profit, but can also become an excellent launching pad for a big business.

Video: mini-factory for the production of bricks of the original form in the Lego style

Production of equipment in Russia is represented by companies: Trademark"SKIF", Shenzhen Realan Computer Products Ltd, "Silium" LLC, "Chulkov" LLC, Trolley to the warehouse, LLC, Modern Mechanics, LLC "LOCOMOTIVE-SERVICE ROSTOV", LLC Production company "Industrial equipment, LLC Ardsystems, COOLTECH / COOLTECH You can find a suitable one among 1113 equipment manufacturers in Samara, Moscow, St. Petersburg, Omsk, Yekaterinburg, Novosibirsk, Kazan, Penza.

To refine your search, you can go to one of the subcategories: " Retail store equipment", "Equipment for production", "Equipment for car service", " Refrigeration equipment", "Storage equipment", "Equipment for the service sector", "Metalworking equipment", "Woodworking equipment", " sewing machines", "Packaging equipment", "Forging equipment", "Computer equipment", " Medical equipment", "Lighting equipment", "Pumping equipment", "Heating equipment", "Oil equipment", "Mining equipment", "Testing equipment", "Other equipment".

If you are looking for a specific product, then look at the products in the "Equipment" category. These manufacturers offer a wide range:

- Sports complexes "SKIF PRO" for sports and playgrounds,

- Rocking chairs "SKIF PRO" for playgrounds,

- Mr.NUC mini computer,

- fanless silent computer,

- Frequency converter 0.75 kW (Silium),

- 1 phase frequency converter 0.75 kW (for 220V network),

- Roller cable releasing RV 700.,

- Roller cable releasing RV 500.,

- Hydraulic cart Lema lm 25 115,

- Hydraulic trolley Otto-Kurtbach OK 25 115,

- and other goods.

In addition, you can familiarize yourself with the offers from equipment manufacturers to search for representatives in the section

self-tapping screw- a type of fastener that allows, when connecting different parts, to cut a thread in one of them. Very convenient when working with wood, polymer and metal materials due to skipping an intermediate operation - drilling holes for the connecting element.

They have found wide application in construction industry; used in the manufacture household appliances; used in mechanical engineering.

Opening a business for the production of self-tapping screws, today, is quite profitable.

To do this, you need to go through several stages:

- get acquainted with the technology of production of self-tapping screws;

- study machines and production lines;

- draw up a business plan.

Self-tapping technology

The technological chain for the production of self-tapping screws consists of several key segments:

The technological chain for the production of self-tapping screws consists of several key segments:

- The raw material, as a rule, a wire of a certain diameter, enters the automatic machine, where an intermediate semi-finished product is formed: cutting to the required length occurs; further, by means of a cold heading process, the head of the future self-tapping screw is pressed.

- On the conveyor, the workpieces enter the machine, where the vibration grippers are directed to the formation of threads in the next machine.

- Almost finished self-tapping screw undergoes heat treatment followed by washing.

- The next stage is chemical treatment, for the purpose of applying anti-corrosion coatings.

- The last treatment is drying.

- The technological chain ends quality control and packaging.

From the description of the production technology, it becomes clear that several different stages are required for the production of products, respectively, various machines and equipment.

Machine tools and equipment for self-tapping products

In essence, the production of self-tapping screws is carried out on a small production line. It consists of:

- Cold heading equipment. Conventionally, it is divided into two groups: with a semi-protective casing and a protective casing. They differ in productivity, control system, automation, manufactured assortment. The simplest models are focused on the production of one type of product.

More expensive machines allow you to expand the range to the production of screws, screws and other types of hardware. The productivity of machines, on average, is in the range of 40 ... 250 pieces / min. Naturally, the prices between simple models and high-performance ones differ several times. Separate models can additionally form a drill on the nose of the self-tapping screw. - thread rolling machine. Provides thread rolling by means of a flat interchangeable die. It has the ability, depending on the model, to vary the thread pitch.

- Thermal hardening furnace. Gives the self-tapping screw a surface strength on the Brinell scale of at least 55 units. The process of heating to a temperature of about 1000 degrees Celsius lasts about one minute, followed by cooling (tempering) in a special quenching medium.

- Galvanic line. Designed to form an anti-corrosion coating on the surface of the self-tapping screw. This can be oxidation, phosphating and zinc coating. It consists of several baths where electrochemical coating reactions are carried out.

- Centrifuge. Carries out hot air drying of finished self-tapping screws after washing from the remnants of chemical solutions in the electroplating process.

Buying one item from the entire production line makes sense if it is a replacement for a completely failed equipment or in order to replace it with a more advanced device.

To start a full cycle for the production of self-tapping screws, economic calculations should be made for the entire technological chain.

There are several manufacturers from Europe, China and Taiwan on the market. When compared by technical parameters, the most cost-effective would be the acquisition of a production line in Taiwan. You can combine and make a line of machines from different manufacturers.

For example, it is possible to integrate a cold heading machine made in Ukraine (Odessa) into the process of equipment installation. The rest of the machines are made in Taiwan or China.

Before starting any business, it is necessary to work out the economic component of the production process. preliminary analysis possible profitability or unprofitability of the project is described in the business plan.

Business plan for the analysis of the production of self-tapping screws

In this theoretical project, an analysis of all operations is carried out, from the supply of raw materials, the purchase of equipment for production, and ending with the sale of products.

The main components of a business plan

The very first step what needs to be done is to conduct a market research on the demand for the products that are supposed to be produced. This is revealed through a needs analysis. retail chains, markets and production: construction organizations, mechanical engineering and furniture enterprises. The data is recorded, they will be needed for further calculations of the profitability of production.

Advice: studying the market of self-tapping screws, it is useful to determine how much is represented by domestic products, what is accounted for by imported goods.

Second step- to identify the most requested items. This will determine where to start. manufacturing process: to purchase machines with a narrow specialization in assortment filling or to set up a full-fledged production line.

It may turn out that at first it is more profitable to put production on a small assortment. With development, gradually improve and increase the production capacity by acquiring more advanced machine tools.

Example:

- when installing drywall on a metal profile, the most used is a sharp oxidized metal self-tapping screw 25 mm long;

- for fastening plywood, sharp oxidized self-tapping screws 45 ... 55 mm long are most used.

next step – selection of a place for future production.

There are a number of requirements for the location of the future mini-workshop:

There are a number of requirements for the location of the future mini-workshop:

- access roads, minimum - gravel road;

- providing power grid, - power consumption of the production line can reach several tens of kilowatts;

- sewerage and water supply systems must be connected to the site;

- on total area territory it is necessary to place a production line With convenient access to all machines; travel routes should ensure free delivery and return transportation, respectively, of raw materials and finished products.

From the foregoing, it follows that the optimal solution is to rent space in idle production shops, workshops.

Preliminary data on rent and costs for energy, water, heat supply must also be entered on paper.

Choice of manufactured product range.

The produced nomenclature affects the rate of return of the project:

- the wider the range of hardware products is presented, the more potential consumers there will be production products, and accordingly, the turnover of capital will accelerate;

- a wider product range, automatically implies the availability of productive machines, but with higher costs for their acquisition.

Note: item size future products and therefore the required production line, are interconnected with the demand for hardware.

- An important but necessary part of the cost is wage staff. In production, as a rule, a piece-bonus system of material remuneration is adopted, in other words: “we did more - we got more”.

Tip #1: at the stage of increasing production, for the first six months it is better to use a fixed tariff scale, with a gradual transition to more progressive payment methods.

Tip #2: It is not advisable to save on the qualifications of workers. Due to his experience, a professional master will be able to complete the work faster and with best quality.

Economic calculations for raw materials

The cost of the raw material is an important component in the final price of a self-tapping screw. But cheap is not always good.

- First: the price of raw materials must take into account fare for delivery to the place of production.

- Secondly: solid, high-quality metal cannot differ much from average price by market.

If so, then the metal either does not meet the requirements of GOST, or the question arises about the origin of the product.

Note: with far-reaching plans, it is better to focus on reliable and reputable suppliers who can ensure the rhythm of deliveries, and, with further successful work, will be able to provide various deferrals for payment of the original products.

In a separate paragraph, it is necessary to consider the issue sales of products. Without the establishment of sustainable sales, the idea of organizing the production of self-tapping screws is doomed to failure.

Potential consumers of hardware products:

- construction organizations, including small finishing teams;

- enterprises producing household appliances;

- furniture workshops, up to private small workshops;

- manufacturing enterprises associated with the production of building and finishing materials;

- markets with a building assortment;

- trade organizations, both large (wholesale) and small shops.

The most likely and convenient in cooperation will be large and medium-sized construction, industrial and furniture organizations, as well as wholesale trade enterprises and large hardware stores.

Benefits of working with them:

- work is carried out under long-term contracts;

- the opportunity to receive prepayment for the release of future products;

- permanent source of sales;

Work with small businesses, at the stage of production, should be based only on the principle of prepayment.

Implementation and deferred payment is unprofitable for several reasons: small organizations will not bring much revenue, but in case of delays in payments, a significant amount of time will be spent on receiving debts than on engaging in their main production.

Basic costs, one-time and current

For intermediate calculations and the final preparation of a business plan in the financial analysis the following costs are taken into account:

- the cost of the main auxiliary equipment including delivery, installation and connection;

- rent of premises for each month;

- the cost of electricity, water supply for one calendar month;

- employee salaries;

- overhead costs for chemicals, lubricants;

- tax deductions;

- monthly cost of raw materials;

- registration with all fiscal authorities to start activities;

- payment of bank interest;

- overhead costs (range 5…25% of monthly operating costs).

By reducing all these numbers to the given monthly costs, you can estimate the approximate weighted average volume of output.

For such calculations, it is necessary to focus on 25 ... 100 types of product range and the selling price, lower by 10 ... 15% of the estimated one - by prior agreement with customers.

The data obtained is the minimum profitability of production. It will grow as sales increase, respectively - production growth and production cost reduction.

Specific figures for costs are not deliberately given - each region has its own starting opportunities for organizing a business.

With a thoughtful approach, a thorough analysis of the market, a good organization of production, the payback period will be, today, from 1 to 3 years.