The quality management system at the enterprise should operate on the principle of continuous improvement of the quality of all organizational processes. The main thing is to monitor not only the quality of the product itself, but also the level of qualification of the staff, how the adopted development strategy is being implemented. Quality can be quantified: financial indicators company and the ratio of positive and negative customer reviews.

Use of the ISO 9000 quality system

QMS can be certified according to the ISO 9000 standard, which includes a whole series of standards.

The system involves an external audit by the certifying body at the enterprise. Now in our country this procedure is not obligatory, but the presence of such a certificate indicates the reliability of the company and its customers, partners, and the state. Participation in international and national tenders, for example, is unimaginable without an ISO 9000 certificate. The certificate, which is issued in Russia, is issued according to the GOST R ISO 9000 standard. To obtain it, you will need a whole set of documents: PSRN, certificates from the tax office on registration of changes in the company's constituent documents, TIN, OKVED codes, an extract from the Unified State Register of Legal Entities, the charter of the organization and all the changes that were made to it, memorandum of association and licenses with activities permitted to the firm. The documents will need to indicate information about the organization (address, Bank details), as well as describe the full structural diagram of the company, including various divisions. A detailed description is also required. personnel organization, indicating the education and work experience of employees. Registration of the certificate will take from three weeks to two months.

Obtaining a document valid for three years will cost 100-500 thousand rubles. depending on the system in which it is issued.

The introduction of a quality management system in an enterprise will help not only improve the company's reputation. QMS helps to avoid errors in production, in addition, by optimizing all the life processes of the enterprise, costs are reduced. If done right it should get better financial condition firms. Openness to external audit forces managers to reckon with the opinion of ordinary employees, which leads to team cohesion and a greater focus on a specific result.

Basic principles of the enterprise quality management system

There are several principles on which the quality system of any enterprise should be based:

The desire of the client is the main thing. The focus is on customer needs. The company must not only monitor momentary demand, but anticipate the desires of consumers. The foresight of the management will make it possible to change some parameters of the product in time, which can make the company a leader in the market segment.

The leader is the main driver of change. The head of the company must motivate employees to achieve the most positive result.

The approach to management should be systematic. This means that the manager must evaluate both external and internal factors that affect the functioning of the company.

Striving for continuous improvement. This should be the main motive for the activities of a company that implements a QMS. Of course, the costs of research and ongoing audit require material costs, But new technology, which as a result will be used in production, on the contrary, can reduce costs and give the company new push to development.

Employees must be involved in the quality management process. The staff must be interested in the work. Employee motivation is one of the most important elements of the quality management system.

Relations with partners and suppliers should be mutually beneficial. Issues related to the supply of raw materials, or, for example, logistics (which ensures the timely delivery of goods to the consumer) should be singled out in a separate area for which a specific employee will be responsible.

Quality Management System

Quality Management System(QMS) - a set of organizational structure, methods, processes and resources necessary for the overall quality management. It is designed to continuously improve performance, to increase the competitiveness of the organization in the domestic and world markets, determines the competitiveness of any organization. . It is part of the organization's management system.

Modern QMS are based on the principles of TQM. The various parts of an organization's management system can be integrated together with the quality management system into a single management system using common elements. This increases the effectiveness of planning, the efficiency of resource use, creates synergistic effect in achieving the overall business goals of the organization.

QMS certification according to ISO 9000 is widely used. QMS certification is based on independent audits by a third party (certification body).

Basis of the organization

Quality management systems are driven by the requirements of the organization's customer. Consumers need a product (service) whose characteristics would satisfy their needs and expectations. The needs and expectations of consumers are constantly changing, because of which organizations are under pressure created by the competitive environment (market) and technical progress. To maintain ongoing customer satisfaction, organizations must continually improve their products and their processes. The QMS of the organization, as one of the management tools, gives confidence to the top management of the organization itself and its consumers that the organization is able to supply products that fully meet the requirements ( required quality, in the required amount for a specified period of time, spending the specified resources on this). This management tool operates strictly within the framework of the so-called iron triangle of the project.

The QMS is based on eight quality management principles:

- Consumer Orientation- the organization needs to do what the consumer wants now and wants in the future, even if he does not realize it.

- Leadership- since the organization always operates within the limits of limited resources and input data in a competitive environment, only a leader with vision and fortitude is able to ensure the achievement of its goals (mission).

- Staff involvement- since the staff of the organization is its main resource and at the same time the most sensitive stakeholder, the reliance of leaders on it is the key to success.

- Process approach- The organization's QMS is not a static formation and its elements are processes - through which goals are achieved, that is, any changes are ensured through processes.

- System approach to management- implies taking into account all factors affecting the external and internal environment organizations.

- Continuous Improvement- the basis modern management, which implies constant adaptation to past and expected changes in the environment, and sometimes even forms them.

- Fact-based decision making- a reminder that the stability of the functioning of the organization is possible not only on the basis of intuition, but also using measurement data.

- Mutually beneficial relationships with suppliers- along with the principle consumer orientation involves the creation of sustainable supply chains based on mutually beneficial cooperation.

Target

Achieve long-term success by maximizing customer satisfaction, employees, owners and society. The purpose of the QMS is to match the results of the company's processes with the needs of the consumer, organization and society. (compliance with both explicit requirements and implied needs).

Tasks

- Continuous improvement of product quality and reduction of quality assurance costs through the use of the PDCA cycle (Deming cycle), consisting of: planning, acting, analyzing, correcting (eliminating the causes of nonconformity, and not just correcting the results obtained);

- creating consumer confidence in the absence of defects through certification of the quality management system.

Principles

- Establishment needs and expectations consumers and other interested parties of the organization in the field of quality of the product or service.

- Availability policy and goals organization (or a dedicated part of the organization), corresponding to the satisfaction of predetermined needs of consumers (external and internal). (see 1.).

- Statement Scientific schools and directions of management#Process approach in the management of """processes""" and responsible for them necessary to achieve the goals of the organization (or a dedicated part of the organization). Implementation of a process approach in achieving these goals (see 2).

- Determination of the necessary resources and providing those responsible for the processes with them to achieve the goals of the organization (or a dedicated part of the organization) (see 2. - 3.).

- Development and application methods for measuring effectiveness and efficiency each process based on key indicators quality (see 1. - 3.).

- Determination of the mechanisms needed for nonconformity warnings And elimination of their causes. And the implementation of these mechanisms in the QMS processes (see 3).

- Development and application of the process for continuous improvement of the entire QMS(see 1. - 2.).

As can be seen from the definition, the primary element of the QMS is the needs and expectations of consumers (internal and external) of the product or service, business owners, staff and society. The organization's policies and objectives are a response to the needs and expectations of interested parties. And the subsequent process approach completes the description of the way to achieve the goals and implementation long term policy. Each of the above points is the key to any QMS, which are in constant cyclical interaction on the way to the highest possible quality.

Industry QMS

Standardization of the QMS based on the requirements of ISO 9001 provides only the basis for sustainable customer satisfaction, however, each industry has its own special requirements and specificity. To better ensure customer satisfaction, industries create their own industry models of quality management systems in the form of separate standards or in the form of Recommendations for the implementation of ISO9001. The most developed models of quality management systems in industries are:

- ISO/TS 16949 - suppliers of automotive components.

- ISO 13485 - manufacturers of medical devices.

- AS 9100 - suppliers of aerospace components.

- ISO 29001 - petrochemical and gas industry.

- TL 9100 - enterprises in the telecommunications industry.

- IRIS is the rail industry's supply chain.

- ISO 22000 - food supply chain.

- ISO 20000 - service management (this standard is not made according to the structure of ISO 9001, but in general, corresponds to the spirit of TQM).

- IWA 1 - healthcare facilities.

- IWA 2 - educational institutions.

- IWA 4 - local governments.

Notes

Literature

- Lapidus Vadim Arkadyevich, Rekshinsky A. N. Consultant's dialogue with the head of the company. Top management about universal quality(TQM) and ISO 9000 standards version 2000, Center Prioritet ADM LLC, 2005, 88 p.

At the present level of development, the concept of "quality" is considered as a complex component, including the quality of the final product, the quality of management, the quality of delivery or work, the quality of life of people (employees) and society as a whole.

Quality management- is a coordinated and interconnected management activity, built in such a way as to ensure the reliable and uninterrupted operation of the organization.

Management of an organization, in relation to quality, means that all activities are subject to established quality goals, and in order to achieve these goals, a system of plans has been developed in the organization, there are necessary resources actions are taken to achieve the set goals.

Quality management includes four main components:

- quality control;

- quality assurance;

- quality planning;

- quality improvement.

Quality control- this is an activity to assess the compliance of the object of control with the established requirements. Evaluation activities may include measurements, tests, observations, monitoring, verification, calibration, etc. activities that result in the comparison of values of observed characteristics with specified ones.

Quality assurance- is a systematic (regular) activity, through which you can perform established requirements. It includes work on production, management, material support, maintenance etc.

Quality planning- these are actions that provide for the determination of the necessary characteristics of the object and the establishment of their target values. Quality management refers to these activities as setting quality objectives. Also, quality planning includes determining the processes and resources needed to achieve the objectives.

Quality improvement- consists in the implementation of actions by which it is possible to increase the ability of the organization to meet the requirements for the object. Under the concept of "object" quality management considers products, processes, management system and the organization as a whole.

As such, quality management is a fairly large and voluminous section of applied science, which contains both the philosophy of quality management, and theory, and practical methods.

History of the development of quality management

Interest in quality management arose with the emergence of mass industrial production. From the end of the 19th century to the present time, quality management has gone through several stages, which are associated with the development of certain production technologies. These stages do not have clearly defined boundaries. It would be more correct to speak of overlapping stages, because the development and formation of certain management methods and production technologies does not begin and end at one moment.

At the first stage, quality management paid most attention control of parameters and characteristics of products. This stage falls on the end of the 19th, beginning of the 20th century. It is characterized by close attention to the product and identifying problems in the product. During this period, developed and large quality control services appear at the factories, which are engaged in checking each product. Control is usually carried out at the end production cycle and requires the involvement of specially trained inspectors.

The second stage refers approximately to the period of the 20s, 50s of the 20th century. This stage is referred to as the "process control" or "process control" stage. Quality management shifts the focus from the product to the production processes. This transition was made possible by the development statistical methods process control and control charts. As a result, it was possible to significantly reduce the cost of control and improve the quality of products.

The third stage of its development was quality management in the period from the 50s to the early 80s. To a large extent, the transition is due to the efforts that have been made Japanese companies to increase the competition of their products. This stage can be called the "quality improvement" or "quality assurance" stage. During this period, quality management focuses on improving the subsystems of the enterprise as a whole - production processes, management processes, supply processes, personnel management, procurement, sales, product marketing, etc.

The fourth stage began to take shape around the late 60s and early 70s. It is associated with focusing on the most important characteristics of the product for the consumer. During this period, competition between manufacturers increases significantly. Quality management began to pay most attention to quality planning, so this stage can be called the “quality planning stage”.

Quality Management Guru

Quality management is closely associated with the names of many scientists and engineers who have made a great contribution to solving quality problems. The works of a number of them were "catalysts" for the transition of quality management to the next phase of its development.

- Walter a. Shewhart (Walter Shewhart) - developed statistical methods for process control. The use of control charts in production (Shewhart control charts) is associated with his name. Also, Shewhart's work served as the basis for the creation of a quality improvement cycle, known as the PDCA (Plan - Do - Check - Act) cycle.

- Joseph Juran (Joseph Juran) - known for developing the "quality triad". The quality triad includes a cycle of work on quality planning, quality control and quality improvement. Also, Juran is the developer of the concept of CWQM (Company - Wide Quality Management) - corporate management quality.

- W. Edwards Deming (Edwards Deming) - is considered the founder and developer of the concept of "Total Quality Management" (Total Quality Management). He made a great contribution to the development of statistical methods of process control. He is also known for developing a systematic approach to quality improvement, which he was able to present in a simple and understandable form - in the form of a cycle of improvements PDCA (Shewhart-Deming cycle).

- Armand Feigenbum (Armand Feigenbaum) - developed the principles of total quality control. He was the founder and chairman of the International Quality Academy.

- Kaoru Ishikawa (Kaori Ishikawa) is the developer of many quality tools. The most famous of these is the cause-and-effect diagram or Ishikawa diagram. Kaori Ishikawa developed the basic principles of the corporate quality control system and suggested using the "circle of quality" to describe the stages of a product's existence.

- Genichi Taguchi (Genichi Taguchi) - was engaged in the development of statistical methods and their application in industrial production(the so-called "Taguchi methods"). Now these methods are the basis of the 6-sigma concept. Taguchi is also the developer of the methodology for planning industrial experiments. He proposed the concept of improving quality while reducing costs. This concept is based on the concept of “quality loss function”.

- Shigeo Shingo (Shigeo Shingo) - is one of the developers of the well-known Japanese system of planning and production Just-in-Time (just in time). He is also known for creating the SMED (single minute exchange of die) method and the Poka-Yoke (mistake proofing) system, which are now part of the lean manufacturing system.

- Philip Crosby (Philip Crosby) - the developer of the well-known quality program "zero defects". He made a great contribution to the development of quality improvement methods, the basics of which are formulated in the form of 14 steps to improve quality.

Applied areas of quality management

At the present stage of development, quality management has a large theoretical base, which incorporates elements of many sciences. However, from its inception to the present day, quality management has remained applied science. His the main task- plan, create and ensure a quality result (products, management system, processes, infrastructure, habitat, etc.). The solution to this problem is provided by creating application systems that are implemented and run in various companies.

The most famous and popular systems that quality management includes today are:

- ISO 9000 is a quality management system built on the basis of international standards ISO 9000 series. This is one of the most popular and formalized systems. It focuses on the strict regulation of activities, the clear interaction of employees and the continuous improvement of both individual subsystems and the organization as a whole.

- TQM (Total quality management) is both a system and a management philosophy at the same time. TQM is most popular and widespread in Japan, where it was developed. TQM is based on the concepts of Deming, Juran, Crosby and others. The main principle on which the management system is built is the principle of improving everything that can be improved in the company. There are no strictly formalized requirements (for example, as in ISO 9000) according to which the system should be built.

- Quality awards - these can be considered as another variant of the quality system. Different countries have their own quality awards, for example, Deming Prize, Baldridge Prize, EFQM (European Foundation for Quality Management). Prizes are awarded only the best organizations who meet the established award criteria. The set of these criteria is quite broad, and in order to meet these criteria, the organization must apply various quality management methods.

- 6 sigma (6 sigma) - a technique for improving the quality of the organization's processes. It focuses on identifying and eliminating the causes of various nonconformities and defects. 6 Sigma is a set of quality tools and strategies. It was originally developed and used by Motorola, and has gained popularity since the late 80s of the 20th century. The 6 sigma methodology is based on the work of Taguchi.

- Lean(Lean manufacturing, lean production) is a set industrial practices, the use of which allows to reduce costs and improve the quality of the final product. At the heart of the concept lean manufacturing there is a principle according to which the expenditure of any resources of the organization should be aimed only at creating value for the end consumer. Accordingly, any resource consumption that does not add value should be reduced. For this, a set of different methods, techniques and tools of quality management is used. The concept of lean manufacturing became known and spread after the publication of information about the Toyota Production System in the early 90s of the 20th century. This concept is based on the work of Shigeo Shingo.

- Kaizen (kaizen) is a philosophy and a set of practices aimed at continuous improvement organization processes. This is a Japanese term meaning striving for the best. Kaizen took shape as systems approach to improve performance since the early 50s and is one of the basic approaches in the TQM system. The essence of this approach is to make small and insignificant improvements, but to do them constantly (daily). As a result, after some time, a large number of small improvements lead to major improvements. In this regard, Kaizen expresses the well-known law of the dialectic of the transition from quantity to quality.

- Best practices (best practice) are a set of methods and techniques that allow you to get a quality result. Qualitative result refers to the results of the best companies in the industry. The dissemination of best practices began in the early 90s of the 20th century. As a rule, they are formed in the form of collections or standards. These standards contain requirements for the use of certain methods, including quality management methods.

This is not the whole list of methods and systems that have been developed and used in quality management. Currently, new concepts and methods for quality management are being formed. And the very concept of "quality" is becoming more and more multifaceted.

Oleg Levyakov

WHAT IS QMS?

The material was prepared by Levyakov O.M.

"Those who know do not speak, those who speak do not know." Lao Tzu.

An attempt to find out what a QMS is, by means of a direct reference to the text of the ISO 9000 series standards, usually ends with one thing: the QMS is simply regarded as another "scam" of Western management!

This is due to the fact that the texts of the standards are read most often in a “terrible” translation - the so-called “tracing paper” from English into Russian, completely separate from the necessary interpretation of some requirements, which, although they were borrowed from the socialism we lived through, were brought by the pragmatic West to the working class. states.

Moreover, translation from one language to another is much more difficult than it might seem to a non-specialist, because with the help of the same words, a language can sometimes reflect completely different processes (including management processes). It may happen that when translating from in English into Russian it will be very difficult to find the right Russian word that would fully reflect the term, especially born in a capitalist country.

For example, for us the word “management” 100% means strict administration, and this is only one of the possible meanings of the English word “management”.

The word "management" was put into use in Russian only out of necessity, so as not to lose its main semantic load: management is a methodology for detecting and correcting one's mistakes!

And what are the terms validation and verification worth?

In addition, domestic publications are also trying to “create additional fog” in order to convince a potential customer to contact them for clarification and advice.

I did not want to talk about it here, but another reason may simply be related to the misunderstanding of the essence of things by the authors of such publications themselves.

To be honest, this is exactly the attitude I had after the first acquaintance with the previous version of the ISO 9001-1994 standard!

But as I grew into the topic while working as a consultant, I began to understand the “main military secret” of the QMS!

The paradox is that when reading the standard, even abstracting from the quality of the translation, it is really very difficult to notice it, because everything is constantly focused and “tied” to achieve customer satisfaction! And if you are interested in reducing the cost of production or, for example, reducing the time to bring a new product to the market? What does the “satisfaction” of the Consumer have to do with it, when it is “not yet”?

That is why let's start with a simple question: - what is the QMS for? The shortest answer is to increase the likelihood of achieving planned results. production activities.

Now let's think about what we need to do for this!

From a high school biology course, we know that in nature there are only two types of reflexes, conditional and unconditioned. Obviously, the ability to find and sometimes avoid a rake is not given to us from birth - this is a conditioned reflex. The repetition of these situations allows us to fix the causal relationship between our actions and results.

When hundreds of people pass through obstacles, one of them can come up with a technology to eliminate them. And if it is documented and everyone is trained, then everyone will achieve their goals faster (without obstacles, then!) This is the basis of the evolutionary principle of development.

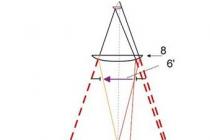

And the basic principle of the QMS - see Fig. 1.

Rice. 1. The concept of the semantic content of the QMS

Why is it so necessary to document knowledge and experience?

Because the circle of direct interaction of top management is 5-10 people, and it is they who “mediate” its management, its decisions, its vision. It is on them that it largely depends whether the desired and actual results of management will coincide. And here, just the “correct” statement of the problem, just the organization and just control, is no longer enough. Here, it is already necessary to negotiate with all the company's personnel - about a common understanding, a common vision, about what we want to have as an output. In the absence of this unity, we are faced with a situation where each of the participants in our business process understands it somehow very differently. And the result he also gets is “his own”, and may even differ significantly from what your company needs.

It is to prevent these dangers that documents arise that define, regulate, distribute rights and responsibilities - internal standards and regulations of the company - see Fig. 2, which shows the concept of the impact of documentation of actions on the quality of production activities.

Rice. 2. The concept of the impact of documentation of actions on the quality of production activities

Rice. 3. System content of the QMS concept

The structural content of the QMS concept in its most general form and in accordance with the architecture of the requirements and principles of the ISO 9000 series of standards is shown in Fig. 4.

Fig.4. Structural content of the QMS concept in accordance with the architecture of the requirements and principles of the ISO 9000 series standards

The strategy for the “correct” implementation of the QMS concept shown in Fig. 3 and 4 is shown in Fig. 5.

Agree that without mutual agreement and internal adoption of these new rules (QMS), the system can easily turn into a sham. Because without an “agreement” there is no such “transmission” of internal energy and the conviction that this particular thing is “right” and that it should be done right in this way. This is where the requirements of the ISO 9001 standard for ensuring staff involvement and management leadership will help you - see Fig. 5.

Rice. 5. Strategy for the implementation of the construction of the QMS

Moreover, the introduction of the QMS should be carried out only on the initiative from above, since this process requires a change in the established order of doing business, the stereotypes of employees of the enterprise.

If there is no interest in the QMS from the management side, then the probability of success tends to zero.

But because the main task of the QMS is not to increase the efficiency of the work of employees. Most often, such changes are the goal of the manager or owner, and this brings an additional headache to the employees themselves. As a rule, labor costs do not decrease with the introduction of QMS. The benefits of QMS are clear only top management. Usually they come down to improving the manageability of the enterprise and the possibility of expanding the business. But ordinary employees, with rare exceptions, always meet such changes with hostility.

For at least two reasons.

The first is the system of accounting and document flow that has developed in the company, which is presented to all employees as the “only possible” and, therefore, not subject to revision.

The second is that for the full-fledged work of the QMS, the collection and monitoring of much more information is required (for example, quality records management - which requires greater discipline of employees) than before. Of course, the increase in the volume of work cannot please either ordinary workers or financiers, who are tuned in to savings and reducing staff.

So what to do?

Practice allows us to identify the following main success factors for the implementation of the QMS - see Fig. 6.

Rice. 6. The main success factors for the implementation of the QMS

Let's comment on the main ones.

1. Conducting a preliminary survey and subsequent modeling necessary business processes. Any business consists of interconnected (correlated) actions. The implementation of these processes should be provided with resources (monetary, labor, material, informational, etc.). Each process has its own cost. The totality of enterprise processes makes it possible to calculate the actual actual cost of the business. And then you can competently solve problems financial planning, analysis, pricing, product quality, etc.

Achieving business transparency by identifying the business processes of the enterprise in accordance with the set goals is an urgent task for most enterprises, especially those that are actively developing.

The business model of the company is not only the basis for managing the organization. High business transparency, simplicity and accessibility of the system description allows you to develop the initial terms of reference for setting up a resource management system (for example, ERP systems) and develop new requirements for improving (tuning) the resource management system. This allows you to provide the necessary resources, the required quality, in the required quantity, in the right place, at the specified time, for acceptable price, and reduce production costs, thus increasing the competitiveness of the company.

Based on the business model, managers receive the necessary administrative documents ( job descriptions, regulations, other management regulations, operational and strategic reports on the availability and movement of resources in the company, etc.).

This modeling work also forms the basis for the implementation of process management.

2. The key condition for success is the personal interest of one of the first persons of the organization in the results of implementation. In any case, the staff experiences some stress when implementing the QMS. Without the strong will and power of leaders, implementation cannot be successful.

3. Work with management - the formation and coordination with the top officials of the company of its mission, goals and objectives in the field of quality - the invisible and visible presence of the manager in the framework of the implementation of the system is a must, and his role is as simple as person concerned may not be enough.

This is especially evident when developing indicators and metrics for the work of departments.

An example of the goal setting concept, for example, project business- see fig. 7.

Rice. 7. An example of the concept of defining goals, for example, a project business

4. Formation of the implementation team and its training - no comments are needed here.

One can only add an example of personnel training for an external audit as a way of additional training.

5. Availability in staffing the position of Quality Director.

His alternative in the form of a representative of the management in the field of quality is just a crafty cover for the irresponsibility of the management itself.

For example, it is already accepted that the procurement system is headed by the commercial director, the training system is headed by the HR director, the finance system is headed by financial director. It is quite logical to conclude that the quality system should be headed by the Quality Director!

6. Staff motivation.

This is a delicate matter and is solved in each specific case in different ways.

Rice. 8. The concept of creating a system of personnel motivation

But for all that, it is very important to explain to the staff that the implementation of the system will only make the whole company better - see Fig. 9, and thus hint at the "inevitability" of change.

Rice. 9. The concept of improving production activities after the implementation of the QMS

7. Implementation of implementation in the form of a project. Must be developed and agreed upon by the high level the most detailed schedule of the Project for the implementation of the QMS with responsibility for the delay or disruption of its implementation.

Now it's time to “link” everything you read to the most important thing - to the concept of the quality of the company itself.

Rice. 10. Architecture of the concept "Quality of the company"

Thus, the QMS is not a “scam” at all, but a proven tool for organizing production activities, and aimed primarily at increasing the likelihood of the company achieving the planned results and, ultimately, improving the quality of the company - see. Fig.10.

But the staff is far from always able to get to the bottom of this essence!

But if you planned as a result to achieve only complete satisfaction your Consumers, then we can say that you have built the QMS in accordance with the ISO 9001 model!

So QMS is a way of organizing production processes ensuring the achievement of planned results.

Thus, the QMS resembles an “iceberg in the ocean”: it has a tiny surface part in the form of a very small text of ISO 9001 and a huge underwater part of reengineering and business modeling, motivation systems, corporate culture, standards development, etc. - see Fig.11

Rice. 11. "Iceberg" SMK

But very often in the CIS, specialists consulting firms who conduct training during the implementation of the QMS, poorly reveal the essence of this entire “iceberg”, limiting themselves to formal adherence to the standard.

Resume (in a simple and understandable language for the staff).

The quality management system serves to improve the quality of business management.

It is called QMS and is a company's business process management system - see Fig. 4.

The QMS provides clear instructions for all occasions of the employee's life: what, where, when and why. Moreover, when a quality system is introduced, an employee writes his own instructions.

So that different companies, when working with each other, are sure that there will be no surprises from the partner and there is a certification procedure according to the ISO 9001 standard, which clearly defines what the governing documents should be in the company, how records of production, purchases and sales should be kept, how traceability and identification of products should be carried out, how suppliers should be selected, how to measure the effectiveness of the enterprise, what corrective and preventive actions to take, what management needs to analyze, etc. and so on.

The QMS provides for the creation of a business model of a company, where each service or process of obtaining a product is considered as a link in a continuous chain, at the end of which stands the Consumer. The model assumes the emergence of new horizontal links and relationships aimed at the disappearance of interfunctional barriers, since quality is often lost precisely at the junction of functional units.

After internal and external audits, analysis by management or at the initiative of the employee, these instructions can (and should) be improved and optimized. The meaning of all this is to leave the owner of the enterprise with a documented algorithm for the most effective actions of the employee, in case the old experienced master "Uncle Vasya" fell ill or retired.

In order for the regulation to be not just clear, but also good, corrective and preventive actions are taken to improve processes and such actions should be carried out on a regular basis.

Thus, the QMS turns out to be not a "stupid bureaucratic machine" for stupid foreigners who cannot take a step without instructions, but in fact very effective tool improving business quality.

And quite simply: The QMS turns a heroic guerrilla unit into a well-trained regular army battalion!

quality management?

Summarizing the various definitions developed by ISO (International Organization for Standardization) − international organization for standardization, a worldwide federation of national standards organizations (ISO member committees). We can say that the QMS is a documented management system that allows you to apply a process approach to all aspects of the organization's activities and provides effective interaction and improving working practices and processes, including products. This system management is based on standards and principles that determine the methods of implementation effective management quality. The quality management system (QMS) is part of the overall company management system, which operates to ensure the stable quality of products and services provided. The methodology of the quality management system (QMS) is based on the principles of system and process approaches. The principle of consistency is implemented in the management of the company as a system of interrelated processes aimed at achieving the set goals. The process approach allows you to identify the processes that have the greatest impact on the achievement of goals. It identifies and measures process inputs and outputs, internal and external customers, suppliers and other interested parties. Thus, the processes performed within the product life cycle determine the construction of the organizational structure of the enterprise. The execution of all processes for all elements of the organizational structure is documented. At the same time, the effectiveness of the functioning of the quality system at each level is confirmed by the relevant quality data. Respectively, modern system quality management combines organizational structure, documentation structure and information structure, as well as processes that affect quality. Obviously, for effective functioning, these structures must be interconnected, fully cover the organization and all processes.

The introduction of a quality management system and its subsequent certification bring companies a number of strategic and economic benefits:

- Obtaining an advantage over competitors when participating in Russian and international tenders, exhibitions, auctions.

- Satisfying the requirements of suppliers for the presence of a functioning QMS in the company.

- Fulfillment of a condition for receiving a state, military or any other order that is funded from the federal or local budget.

- Improving the image and investment attractiveness of the company in the eyes of foreign and Russian partners.

- Improving the image of the organization in the region and industry, which is important for achieving superiority in the market.

INTERNAL:

- Improving the management system and increasing its effectiveness and efficiency;

- Optimization of business processes and increase in their manageability;

- Improving the interaction of all divisions, services of the company, as well as management levels;

- Optimization of the company's document flow, facilitating the transition to electronic document management.

- Improving the quality of products / services through improving the quality of all processes;

- Improving the quality of personnel work through a clear, specific, targeted distribution of responsibilities, rights and powers.

- Creation of a base for the rapid and effective implementation of other quality and safety management systems (ISO 14000, HACCP, GMP, etc.)

Purpose

QMS is designed to quality products or services of the enterprise and "tune" this quality to the expectations of consumers (customers). At the same time, its main task is not to control each unit of production, but to make sure that there are no errors in the work that could lead to marriage (poor quality of products or services).

To understand why quality assurance works the way it does, the following points of the quality philosophy help. The cause of marriage is always wrong actions. And in order to avoid them, it is necessary to formalize (describe) the right actions to create high-quality products or services, develop instructions for right action and control these activities.

Structure

QMS as a system consists of the following elements: organization, processes, documents, resources.

According to ISO, an organization is a group of people and necessary means with a distribution of responsibilities, authorities and relationships. In other words, the organization is understood as a set of elements of the organizational structure related to quality, the rules for their interaction, as well as the personnel responsible for quality.

Process is a set of interrelated and interacting elements of activity that transforms “inputs” into “outputs”. In this case, the "inputs" of the process are usually the "outputs" of other processes. Processes in an organization are typically planned and executed with the goal of adding value (from "input" to "output").

The concept of procedure is of great importance in the QMS. A procedure is an established way of carrying out an activity or process. Thus, a procedure can be called a process (or a set of processes); on the other hand, it is formalizing The right way process execution.

Document - information (meaningful data) placed on the appropriate medium. Other organizational and administrative documents of the enterprise, for example, “Regulations on subdivisions” and “Job instructions”, should be associated with the documents of the quality system.

QMS resources - everything that provides quality (human, temporary, etc.).

Thus, the QMS is a system consisting of an organization, processes, documents and resources, aimed at the formation of policies and goals in the field of quality, as well as the achievement of these goals.

The presence of a QMS is necessary for any organization that supplies products for export or takes care of its own image, participates in tenders or seeks to expand sales markets and acquire new customers. The international standard ISO 9001:2008 is the most widely used standard for the creation and implementation of a quality management system.

World practice has shown that the application of the principles of the international standard ISO 9001:2008 (or the Russian state standard GOST R ISO 9001-2008), today is a reliable tool for building effective system management, increasing competitiveness and creating favorable conditions for investment growth.