On July 12, 2018, the Krasnoye Sormovo Shipyard (part of the United Shipbuilding Corporation) launched the third dry-cargo motor ship of the RSD59 project, which is being built for the Pola Rise company. This was reported by the press service of the shipyard.

Representatives of the customer, designers, shipbuilders themselves and the townspeople took part in the event on the occasion of the descent. Traditionally, a bottle of champagne was broken on the side of the ship. Anastasia Khalilova, Director of the Directorate of Railway Transport of the State Transport Leasing Company (STLC), became the godmother of the dry cargo ship.

"Pola Sofia" is the third RSD59 dry-cargo ship launched by the Krasnoye Sormovo shipyard this year. Recall that the first one, Pol Makariy, left the stocks of the shipyard on April 20, 2018, the second one, Pol Filofey, on June 8, 2018. Both have already been handed over to the customer and are successfully operated.

Recall that in accordance with a tripartite contract with STLC and shipping company Pola Rise, Krasnoye Sormovo shipyard undertakes to deliver to the customer in 2018 five dry cargo ships of the RSD59 project.

According to the interim CEO"Krasny Sormovo" Mikhail Pershin, the plant successfully copes with the task.

“This is not an easy project. As the construction progresses, we have to solve a lot of new issues, since we are the first to start building such bulk carriers in the country. Unlike previous projects, the designer provides for a number of innovations in RSD59, fully tailored to the requirements of the customer. But we have a very flexible production, the workshops are equipped so that they can be "reformatted" quickly and without loss at any time for any order, any type of vessel. And, most importantly, what allows us to move forward, of course, is personnel - our employees are all professionals," the head of the enterprise noted.

Dry-cargo vessel of the RSD59 project is a self-propelled dry-cargo single-deck vessel with two cargo holds, with two full-revolving propellers, sea and mixed "river / sea" navigation "Volgo-Don max" class. Designed for the transportation of general and bulk cargo, packaged lumber, round timber, scrap metal, metal in bundles and rolls, bulky, long and heavy cargo, coal, dangerous goods and goods of category "B". Navigation areas: sea areas corresponding to the limited navigation area R2 with a wave height of 3% probability of 7.0 m, with a distance of no more than 100 miles from the place of refuge and with an allowable distance between places of refuge of no more than 200 miles, inland waterways of Russia, subject to restrictions , including VPVP and VDSV.

Main characteristics

Length 140.88 m, width - 16.98 m, depth - 6 m, deadweight river / sea - 5128/7535 t, cargo holds volume - 11292 m, number of holds - 2, river / sea draft - 3.6 / 4.53 m, autonomy, day - 20/12.

Vessel class: КМ Ice2 R2 АUT1-ICS CONT (deck, cargo holds Nos.1.2) DG

The RSD59 project was developed by the Marine Engineering Bureau - Design St. Petersburg.

The working design documentation of the vessel was made by the Volga-Caspian Design Bureau.

Tags:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Series of five dry cargo ships of the RSD59 project will be built by Nevsky Shipbuilding and Ship Repair Plant LLC by order of Pola Rise LLC, with which there were contracts on December 29, 2016.

The vessel of the RSD59 project is intended for the carriage of general and bulk cargo (including grain), packaged lumber, round timber, scrap metal, metal in bundles and coils, bulky, long and heavy cargo, coal, dangerous goods of classes 1.4S, 2, 3, 4, 5, 6.1, 8, 9 in accordance with MK RID and Appendix B of the Code of the Armed Forces.

The main advantages of the dry-cargo vessel of the RSD59 project are: the presence of a long hold L = 77.35 meters, which allows transporting CTG, which is relevant for the market of the countries of the Caspian region; the height of the hold is 9000 mm, which allows transporting containers up to 9.6 feet high - “high cube containers” (3 such containers in height); hatch covers of a removable type were installed (opening and closing of each section is carried out using a special gantry crane, which is stowed in the area of \u200b\u200bthe forward bulkhead of the residential superstructure); movement and controllability are provided by two RVKs (better maneuverability in narrow spaces, more cargo space due to a reduction in the size of the MO).

The ships will be built to the class of the Russian Maritime Register of Shipping: KM Ice1R2 AUT1-ICS.

Main characteristics of the RSD59 project dry-cargo vessel: Sea deadweight 7445 tons, river deadweight 5112 tons. The maximum length is 141.0 meters, the overall width is 16.98 meters, the depth is 6.0 meters, the draft in the sea is 4.5 meters, the draft in the river is 3.6 meters. Speed at a draft of 4.5 meters is about 10.2 knots. Crew 11 people. There are 14 seats on board. Power is supplied from two main engines with a capacity of 1200 kW each. Autonomy in the sea 20 days, in the river 12 days. Number of holds 2. The volume of cargo holds is 11200 m2. Container capacity (hold/deck) – 252 (192/60) TEU.

The lead ship in a series of five ships of the RSD59 project "Pola Anatolia" (building number 591): March 27, 2017 metal cutting work. May 18, 2017

(Nevsky Shipyard) On July 5, 2018, it launched the lead multi-purpose dry-cargo vessel with a deadweight of 7150 tons of the RSD59 project "Pola Anatolia", built for the shipping company "Pola Rise", the IAA PortNews correspondent reported from the launching ceremony

Anastasia Letyagina, Head of the Department for Work with Suppliers of PJSC STLC, became the godmother of the vessel.

The General Director of the Marine Engineering Bureau (designer) Gennady Egorov, in his welcoming speech during the solemn ceremony, emphasized that the vessel "Pola Anatolia" is the lead vessel of a new generation of dry cargo carriers RSD59.

“Compared to the previous RSD 49 project, this vessel is more efficient and able to take on board a larger volume of cargo,” he said.

Albert Vygovsky, General Director of Pola Rise LLC (vessel operator), speaking at the launching ceremony, thanked the team shipbuilding enterprise for the work done and noted that "the new vessel is already in demand and there are cargoes for it."

Construction contracts were signed between OOO , PJSC State Transport leasing company"(PJSC "GTLK") and the shipping company LLC "Pola Rise".

The RSD59 project was developed by the Marine Engineering Bureau - Design St. Petersburg.

Vessels of the RSD59 project, in accordance with the classification adopted by the Marine Engineering Bureau, belong to the Volgo-Don max class and have the maximum dimensions possible for the VDSK.

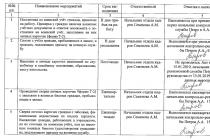

The main characteristics of the dry-cargo vessel of the RSD59 project:

|

Length maximum |

|

|

Overall width |

|

|

Board height |

|

|

Draft at sea |

in the sea - 4.50 m, in the river 3.6 m |

|

Deadweight at sea at draft |

4.50 m - 7,445 t |

|

Deadweight in the river at draft |

3.60 m - 5,112 t |

|

Autonomy (sea/river) |

(sea/river) - 20/12 days |

|

Number of holds |

|

|

Volume of cargo holds |

|

|

Container capacity (hold/deck) |

252 (192/60) TEU |

|

Main engine power |

|

|

Crew/Seats |

11/14 people + pilot |

|

Draft speed |

4.5 m - about 10.2 knots |

The vessel is being built to the class of the Russian Maritime Register of Shipping KM Ice2 R2 АUT1-ICS

The vessel is intended for the carriage of general and bulk cargo (including grain), packaged lumber, round timber, scrap metal, metal in bundles and coils, bulky, long and heavy cargo, coal, dangerous goods of classes 1.4S, 2, 3, 4, 5, 6.1, 8, 9 in accordance with MK RID and Appendix B of the Code of the Armed Forces.

Such dry-cargo ships are being built in Russia for the first time and have no analogues. They are more maneuverable and significantly outperform dry cargo ships of the same class previously built in the country in a number of parameters.

The main advantages of the RSD59 dry-cargo vessel:

The presence of a long hold L = 77.35 m, which allows transporting CTG, which is relevant for the market of the countries of the Caspian region

The height of the hold is 9000 mm, which allows transporting containers up to 9.6 feet high - high cube containers (3 such containers in height)

Hatch covers of a removable type are installed. Opening and closing of each section is carried out using a special gantry crane, which is stowed in the area of the bow bulkhead of the residential superstructure

Movement and controllability are provided by two ARCs (better maneuverability in narrow spaces, more cargo space due to a reduction in the size of the MO)

LLC is located 40 km from St. Petersburg in the city of Shlisselburg on the left bank of the Neva River and is one of oldest enterprises water transport in the North-West of Russia. He has been involved in shipbuilding since 1952. Carries out the construction of sea and river vessels various types and appointments and all types of ship repair. The ship-lifting slipway of the Nevsky Shipyard allows launching and lifting for repair of ships up to 150 m long and with a dock weight of up to 4800 tons.

The Krasnoye Sormovo Shipyard (part of the United Shipbuilding Corporation) continues the construction of dry-cargo motor ships of the RSD 59 project. On August 17, the company launched the fourth of five ships this project under the name "Pola Feodosia" for the Russian shipping company "Pola Rise".

The descent ceremony was opened by the head of the Nizhny Novgorod region Gleb Nikitin. He noted the great importance of the plant for the regional industry, spoke about the participation of the enterprise in regional programs to increase labor productivity and introduce new technologies, stressed that the plant has a great and good future.

- The government of the Nizhny Novgorod region actively defends the interests of "Krasny Sormovo" and other Nizhny Novgorod enterprises, seeking to place new orders in our region, - said G. Nikitin. He also added that the possibility of creating a special economic zone in the Nizhny Novgorod region is being worked out. – For this, we have all the necessary sites and the anchor resident – Krasnoye Sormovo.

It is symbolic that the wife of the head of the region Ekaterina Nikitina became the godmother of the vessel. She broke the traditional bottle of champagne on the side of the ship so that the ship would be lucky.

USC First Vice-President Leonid Strugov noted that the plant is one of the leading USC enterprises, and the merit in this is, first of all, the employees of the shipbuilding enterprise.

Mikhail Pershin, Acting General Director of the Krasnoye Sormovo Shipyard, expressed his gratitude to the enterprise’s workforce, which once again proved with its professionalism the ability to cope with tasks of any complexity, as well as to all those who took part in the construction of the vessel: the designer who created a fundamentally new, relevant and in demand dry-cargo ship project; to the customer, who knows well the capabilities of the plant and entrusted the Sormovichi people to build the first dry cargo ships, which had no analogues in Russia before.

At the end of 2016 Krasnoye Sormovo plant signed a tripartite contract with the State Transport Leasing Company (STLC) and the shipping company Pola Rise for the construction and delivery in 2018. five dry-cargo vessels of the RSD 59 project. The keel laying of all five vessels took place in autumn 2017. Thus, the Krasnoye Sormovo plant was the first in the country to start construction of river-sea dry cargo ships, which significantly exceed the vessels of previous projects in their maneuvering and running characteristics.

To date, three vessels of the RSD59 project - "Pola Makaria", "Pola Sofia" and "Pola Filofei" - have already been transferred to the customer and are actively operated in accordance with their purpose. The transfer of the fourth will take place after passing the mooring and sea trials. The construction of the fifth, extreme, bulk carrier is at the final stage.

Technical characteristics of the RSD59 project

Self-propelled dry-cargo single-deck vessel with two cargo holds, with two full-revolving watercraft, sea and mixed "river / sea" navigation "Volgo-Don max" class. Designed for the transportation of general and bulk cargo, packaged lumber, round timber, scrap metal, metal in bundles and coils, bulky, long and heavy cargo, coal, dangerous goods and goods of category "B". Navigation areas: sea areas corresponding to the limited navigation area R2 with a wave height of 3% probability of 7.0 m, with a distance of no more than 100 miles from the place of refuge and with an allowable distance between places of refuge of no more than 200 miles, inland waterways of Russia, taking into account restrictions , including VPVP and VDSV.

Main characteristics

Length 140.88 m, width - 16.98 m, depth - 6 m, deadweight river / sea - 5128/7535 t, cargo holds volume - 11292 m, number of holds - 2, river / sea draft - 3.6 / 4.53 m, autonomy, day - 20/12.

Vessel class: КМ Ice2 R2 АUT1-ICS CONT (deck, cargo holds Nos.1.2) DG(bulk, pack)

The RSD59 project was developed by the Marine Engineering Bureau - Design St. Petersburg.

The working design documentation of the vessel was made by the Volga-Caspian Design Bureau.

Reference

PJSC “Plant “Krasnoe Sormovo” is one of the oldest Russian shipyards founded in 1849 The plant has written a special page in the history of domestic military shipbuilding and commercial shipbuilding. For 75 years, Krasny Sormovo has built and modernized more than three hundred submarines and rescue vehicles, 25 of them nuclear-powered. Today, the plant builds commercial fleet vessels that meet the requirements international conventions for reliability and safety. The English Royal Society of Naval Engineers (RINA) has repeatedly included Sormovo tankers in the list of "Significant Ships of the Year".

JSC United shipbuilding corporation is the largest shipbuilding company in the country. Created in accordance with the decree of the President of the Russian Federation in 2007. with 100% shares in federal ownership. The holding includes about 40 enterprises and organizations of the industry (the main shipbuilding and ship repair yards, leading design bureaus). Currently, most of the domestic shipbuilding complex is consolidated on the basis of USC. Russian market- the main one for the state corporation, which also exports its products to 20 countries of the world.

Marine and Oil and Gas Projects group of companies manages shipbuilding projects. Extensive experience in the civil shipbuilding market allows the MNP Group to effectively respond to market changes, comprehensively use resources and ensure accurate execution of shipbuilding contracts.

1939

Order of the Red Banner of Labor

In commemoration of the 90th anniversary of the plant and for outstanding achievements in shipbuilding and mechanical engineering

The first order to the plant

In January 1939, a team of workers from the shipyard of the Krasnoye Sormovo plant finished manufacturing the hulls of two marine combined dredges with a capacity of 750 m3 of soil per hour. The production of such vessels in the USSR was mastered for the first time.

The labor victory of the Sormovites was won on the eve of a significant event: in 1939 it was 90 years since the founding of the plant.

On December 4, 1939, the Decree of the Presidium of the Supreme Soviet of the USSR was issued: “In commemoration of the 90th anniversary of the Gorky Krasnoye Sormovo plant and for outstanding achievements in shipbuilding and mechanical engineering, to award the Krasnoye Sormovo plant with the Order of the Red Banner of Labor.

1943

The order of Lenin

For the successful completion of the task for the production of tanks and armored hulls

Everything for the Victory

1945

Order of the Patriotic War 1st class

For selfless work in organizing the mass production of tanks and other defense products

Everything for the Victory

The Krasnoye Sormovo plant made a significant contribution to the sacred cause of the Victory. It is a technically very difficult task to switch the ship-manufacturing plant to the production of tanks. In a harsh time, when the front was approaching close to Moscow, the Sormovo plant was turned into one of the most important material and technical bases for the country's defense and became the largest arsenal of the Soviet Army. The factory workers adequately withstood all the difficulties and trials of the war, supplying the front with more than 13 thousand T-34 tanks, 23 submarines, as well as 1.5 million shells for Katyushas and thousands of tons of other ammunition.

For services to the Motherland, for the successful fulfillment of government tasks during the Great Patriotic War, the plant's staff was awarded the Order of Lenin (1943) and the Order of the Patriotic War, 1st degree (1945).

Another valuable relic, the Red Banner, reminds of the labor feat of the Sormovichi people. State Committee Defense, left to the plant for eternal storage, which during the war years was awarded for 33 months in a row to the Krasnoye Sormovo plant for high labor results.

1949

The order of Lenin

For services to the Motherland and the Soviet people and in connection with the 100th anniversary of the founding of the plant

TO PEACE RAILS

The Great Patriotic War ended, the Soviet people returned to peaceful labor.

From the first days of the post-war five-year plan, the production of various parts for steam locomotives and wagons resumed and assumed a wide scope. The Sormovo plant becomes the only supplier of wagon wheels in the country, and for Agriculture– supplier of gas generator sets and spare parts for tractors.

On the eve of the 100th anniversary of Krasny Sormovo, more than 2,000 innovators and old production workers were awarded badges "Excellent worker of socialist competition", and more than 180 workers of metallurgical shops were awarded the title of "Best Metallurgist". For services to the Motherland and the Soviet people and in connection with the 100th anniversary of the founding, the plant was awarded the second Order of Lenin. It was the fourth order on the banner of the plant.

1970

Order of the October Revolution

For the successful implementation of the eighth five-year plan and the organization of production new technology.

AT THE TOP OF TECHNICAL PROGRESS

Nuclear missile carrier "Skat"

The largest achievement of the Sormovo school of underwater shipbuilding was the creation and construction of a nuclear submarine (NPS) of project 670 "Skat", armed with cruise missiles underwater launch, which ensured that the submarine reached the starting positions without losing stealth.

In 1967, the Project 670 nuclear submarine was launched. On the eve of the 50th anniversary of October, state tests were carried out, and the lead nuclear submarine Skat was accepted into the Red Banner Northern Fleet.

In 1970, for the successful implementation of the eighth five-year plan and the organization of the production of new equipment, the Krasnoye Sormovo plant was awarded the fifth state award - the Order of the October Revolution.