These semiconductor devices convert solar energy into direct electrical current. Simply put, these are the main elements of the device that we call "solar panels". With the help of such batteries, artificial satellites of the Earth operate in space orbits. Such batteries are made here in Krasnodar - at the Saturn plant. Let's go there for a tour.

Photos and text by Rustem Adagamov

The enterprise in Krasnodar is part of the structure of the Federal Space Agency, but Saturn is owned by the Ochakovo company, which literally saved this production in the 90s. The owners of Ochakovo bought out a controlling stake, which almost went to the Americans.

Large sums of money were invested here and modern equipment, and now Saturn is one of the two leaders on Russian market production of solar and storage batteries for the needs space industry- civil and military. All the profit that Saturn receives remains here in Krasnodar and goes to the development of the production base.

So, it all starts here - on the site of the so-called. gas phase epitaxy. There is a gas reactor in this room, in which a crystalline layer is grown on a germanium substrate for 3 hours, which will serve as the basis for a future photocell. The cost of such an installation is about 3 million euros:

After that, the substrate still has a long way to go: electrical contacts will be applied to both sides of the photocell (moreover, on the working side, the contact will have a “comb pattern”, the dimensions of which are carefully calculated to ensure maximum passage of sunlight), an anti-reflective coating will appear on the substrate and etc. - more than two dozen technological operations in various installations before the photocell becomes the basis of the solar array.

For example, photolithography installation. Here, on the photocells, “patterns” of electrical contacts are formed. The machine performs all operations automatically, according to a given program. Here, the light is appropriate, which does not harm the light-sensitive layer of the photocell - as before, in the era of analog photography, we used "red" lamps ^

In the vacuum of the sputtering installation, electrical contacts and dielectrics are applied using an electron beam, as well as antireflection coatings are applied (they increase the current generated by the photocell by 30%):

Well, the photocell is ready and you can start assembling the solar battery. Tires are soldered to the surface of the photocell in order to then connect them to each other, and a protective glass is glued on them, without which in space, under radiation conditions, the photocell may not withstand loads. And, although the thickness of the glass is only 0.12 mm, a battery with such photocells will work for a long time in orbit (more than 15 years in high orbits).

The electrical connection of the photocells to each other is carried out by silver contacts (they are called shank) with a thickness of only 0.02 mm.

To obtain the desired voltage in the network, produced by the solar battery, the photocells are connected in series. This is what a section of series-connected photocells looks like (photovoltaic converters - that's right):

Finally, the solar panel is assembled. Only part of the battery is shown here - the panel in layout format. There can be up to eight such panels on the satellite, depending on how much power is needed. On modern communication satellites, it reaches 10 kW. The panels will be mounted on a satellite, they will open in space like wings and with their help we will watch satellite TV, use satellite Internet, navigation systems (GLONASS satellites use Krasnodar solar panels):

When the spacecraft is illuminated by the Sun, the electricity generated by the solar battery feeds the systems of the apparatus, and the excess energy is stored in the battery. When the spacecraft is in the shadow of the Earth, the spacecraft uses the electricity stored in the battery. Nickel hydrogen battery, having a high energy intensity (60 Wh/kg) and an almost inexhaustible resource, is widely used on spacecraft. The production of such batteries is another part of the work of the Saturn plant.

In this picture, the assembly of a nickel-hydrogen battery is being carried out by Anatoly Dmitrievich Panin, holder of the medal of the Order of Merit for the Fatherland, II degree:

Assembly site for nickel-hydrogen batteries. The filling of the battery is being prepared for placement in the case. The filling is positive and negative electrodes separated by separator paper - in them the transformation and accumulation of energy takes place:

Installation for electron beam welding in a vacuum with which the battery case is made of thin metal:

A section of the workshop where cases and parts of accumulators are tested for the effect of increased pressure. Due to the fact that the accumulation of energy in the battery is accompanied by the formation of hydrogen, and the pressure inside the battery rises, leak tests - an integral part of battery manufacturing process:

The body of a nickel-hydrogen battery is a very important part of the entire device operating in space. The case is designed for a pressure of 60 kg s / cm 2, during tests the rupture occurred at a pressure of 148 kg s / cm 2:

Batteries tested for strength are filled with electrolyte and hydrogen, after which they are ready for use:

The body of a nickel-hydrogen battery is made of a special alloy of metals and must be mechanically strong, light and have high thermal conductivity. Batteries are installed in cells and do not touch each other:

Accumulators and batteries assembled from them are subjected to electrical tests at installations own production. In space, it will be impossible to fix or replace anything, so every product is carefully tested here.

All space technology is subjected to tests for mechanical effects using vibration stands that simulate the load during the launch of the spacecraft into orbit.

In general, the Saturn plant made the most favorable impression. The production is well organized, the workshops are clean and bright, the people are qualified, it is a pleasure and very interesting to communicate with such specialists for a person who is at least to some extent interested in our space. I left the Saturn in a great mood - it's always nice to see a place where they don't engage in empty chatter and don't shift papers, but do real, serious business, successfully compete with the same manufacturers in other countries. There would be more of this in Russia.

In contact with

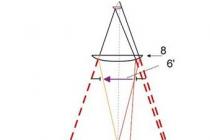

SUBSTANCE: invention relates to energy systems of space objects based on direct conversion of solar radiant energy into electricity, and can be used to create cost-effective large-area solar batteries. Essence: in a space solar battery containing a carrier frame, photocells placed on it, including two conductive electrodes separated by a gap, one of which is made translucent, a coating of materials with a work function less than the work function of the electrode material is placed on the inner surface, and the gap size does not exceed the mean free path of photoelectrons. 5 ill.

SUBSTANCE: invention relates to energy systems of space objects based on direct conversion of solar radiant energy into electricity, and can be used to create space solar panels (SB) of a large area. Solar cells are known, containing a frame, photocells placed on it, including two conductive electrodes separated by a gap, one of which is made translucent Solar batteries based on semiconductor structures various types have a sufficiently high conversion efficiency solar energy . The disadvantages of the known SBs based on the internal photoelectric effect are the complexity of the structure of the solar cell with the use of scarce materials in it, for example, gallium arsenide; the fundamental limitation from below of the thickness of the solar cell due to the multilayer, especially graded-gap, structure of the converter using substrates, various optical and protective coatings and, as a result, the relatively large mass of the solar cell, exceeding the mass of the SB frame made of high-strength materials; sensitivity to the effects of the space environment, in particular to corpuscular radiation, which causes a rapid degradation of performance, reducing the resource. As a result, these shortcomings lead to a high cost of electricity generated by such solar panels. The closest to the proposed technical solution is a space solar battery chosen as a prototype, containing a supporting frame, photocells placed on it, including two conductive electrodes separated by a gap, one of which is made translucent. a homo- or heterostructural layer (s) is used, on which electrodes (for example, optical and barrier) and the necessary coatings are deposited. Current-collecting elements can be made in the form of thin conductive grids formed on the surfaces of the electrodes. The supporting frame is a truss structure made of high-strength, for example, carbon fiber, rod elements, on which FEP is stretched in the form of flexible panels on a mesh substrate, fixed to the frame along the periphery. The well-known SB has a sufficiently high efficiency (practically up to 15-20%) and a small thickness of flexible SB panels (up to 100-200 microns), which facilitates the storage, transportation and deployment of the SB into working condition, for example, from a roll. The disadvantages of the well-known SB are already noted above, typical for semiconductor solar cells. These shortcomings, as a result, are expressed in insufficiently high specific energy characteristics (power does not exceed 0.2 kW / kg or 0.16 kW / m 2) and operational and technological characteristics (significant specific gravity of SB due to FEP, manufacturing complexity, sensitivity to cosmic impacts, etc.), which leads to an increased cost of generating electricity from this type of SB. The aim of the invention is to increase the specific electrical power per unit mass while increasing resistance to external influences in outer space. This goal is achieved by the fact that in a space solar battery containing a supporting frame, photocells placed on it, including two conductive electrodes separated by a gap, one of which is made translucent, on the inner surface of one of the electrodes there is a coating of a material with a work function that is less than work the exit of its material, and the size of the gap does not exceed the mean free path of photoelectrons. The essence of the invention lies in the use in the design of the proposed SB, in contrast to traditional principle external photoelectric effect, while one of the conducting electrodes functions as a photocathode, from which photoelectrons can be knocked out mainly either in the direction of the incident light from the shadow surface of the film, or in the opposite direction from the illuminated surface of the film. Photoelectrons are captured by another film with a conductive electrode, which acts as an anode. Since the cathode and anode films are made of materials with different work functions of electrons, then when the SB is exposed to a light flux, a certain equilibrium potential difference (EMF of the order of 0.6-0.8 V) is established between the films, provided that the gap between the films is less than the length of the free the path of photoelectrons in the gap medium (this condition is satisfied for space vacuum with a weak external magnetic field). Most significantly, conductive (including metal) films can be made much thinner than semiconductor SB panels of the order of 0.5 microns or less, so that the specific characteristics of the proposed SB turn out to be much higher than those of traditional SB. In addition, the sensitivity of the electrophysical characteristics of the proposed SB to the effects of space environment factors (micrometeorites, corpuscular radiation) is much weaker. The production of films and the assembly of SBs from them on a supporting frame are technologically simple, and the conditions of low gravity (weightlessness) make it possible to create light SBs of a very large area, and, consequently, power. The preferred embodiment of the proposed SB is the design, where each of the films with a conductive electrode is made in the form of strips isolated from each other, and the strips of different films in pairs form sections of the photoelectric converter, combined into a serial circuit, in which each rear strip of one of the sections of the converter is electrically connected with the strip oriented towards the Sun of the adjacent section of the converter, and the current-collecting elements are electrically connected with the rear strip at one end of the circuit and with the strip oriented towards the Sun at the opposite end of the circuit. This design has an increased manufacturability in the construction of a large-area SB. At the same time, such a SB design makes it possible to reduce the amount of current flowing through the sections of the solar cell, per unit of generated power, and thereby reduce the film thickness, i.e., further reduce the weight of the SB. In the proposed SB, a coating is applied to the surface of a film with a conductive electrode (photocathode), which reduces the work function of electrons from this film. This can be done, for example, by oxidizing a suitable metal (eg aluminum) film. When the anode is located above the photocathode, the first must be translucent, therefore, in this option The proposed SB conductive film, oriented towards the Sun, can be made of a perforated or mesh structure with the smallest possible shading of the cathode film. The essence of the invention is illustrated by drawings, where figure 1 shows a diagram of the SB with a film photocathode oriented towards the sun; figure 2 shows a diagram of the SB with a photocathode on the back surface; figure 3 shows circuit diagram SB with sectioning; figure 4 shows the equivalent electrical circuit of the SB; figure 5 shows a variant of the design of the Security Council. As shown in figure 1, the SB contains placed on the carrier dielectric frame 1 conductive film, one of which serves as a photoemission cathode 2, and the other an anode 3. The film 2 is located along the surface oriented to the solar light flux 4. Conductive film through the current-collecting elements 5 can be connected to the load 6. According to another version of the SB shown in figure 2, the photocathode 2 can be located along the rear surface, and the anode film 3 is translucent, in particular perforated or made in the form of a fine wire mesh. The electrode materials can be metals such as aluminum, silver, gold, platinum, some alloys, alkali metal oxides and other compounds. Various work The electron yield was obtained for films of the same metal due to the oxidation of one of them or another surface treatment. As shown in figure 3, the cathode and anode films can be made in the form of strips 7 and 8 isolated from each other, and the strips of one type (anode) are electrically connected to the strips of another type (cathode) along the contact joints (seams) 9 so, that here the FEP of a large area is a system (chain) of series-connected power generating sections of 10 smaller sizes. Each section increases the voltage applied to the load 6 in accordance with the equivalent electrical circuit diagram shown in Fig.4. As shown in Fig.5, constructively SB with the scheme according to Fig.3 may contain a folding or prefabricated frame with longitudinal 11 and transverse 12 bearing elements. Fragments of FEP 13 in the form of joined strips of different types are stretched over the frame with their passage through the transverse elements 12 and fastening along the edges on the same elements 12, for example, using dielectric elastic fabrics (grids, braces, etc.) 14. Rigidity of the SB in deployed state is provided by stretch marks 15, tightening the ends of the longitudinal rod elements 11, articulated in their central parts. The functioning and operation of the SB according to the invention is carried out as follows. Either the entire SB in a folded form, or its fragments, which are then assembled into single system. Unfolded in working condition SB is oriented towards the Sun with one of its film surfaces, depending on the type of photocathode (see Fig.1 and 2). Due to the resulting electronic emission an electric field appears in the gap between the films, which creates a potential difference between the anode and cathode films, equal to the difference in the work functions of these films. When connected to the SB through the current-collecting elements 5 of some load 6, an electric current arises in the FEP circuit, which provides the load with the necessary electricity. The preferred area of application of the proposed SBs is high, in particular geostationary orbits, where the impact of the atmosphere, the planet's magnetic field and its gravitational gradient is minimal, which makes it possible to create SBs of a very large area and, consequently, high power. The technical and economic efficiency of the proposed invention can be confirmed by the following estimates. It is known that the efficiency of energy conversion with an external photoelectric effect is 2-10% Considering that the power of the solar light flux near the Earth is approximately 1.4 kW / m 2, the electric power generated by a unit of the SB surface will be about 0.051400 70 W / m 2 , if we take an efficiency of 5% This figure is noticeably worse than that of serial silicon SBs, where 110 W/m 2 is achieved. However, the film thickness can be adjusted to 0.5 µm. Then the mass of 1 m 2 of a film, for example, made of aluminum will be 110.510 -6 2.710 3 1.3510 -3 kg 1.35 g for a thickness of 0.5 microns. From here, the specific electric power (by weight of the FEP), taking into account the use of two films, will be For a FEP with a specific mass of 25-10 g/m 2 , the specific electrical power of the SB will be ![]() This main indicator of the proposed SB is almost 20 times higher than the same indicator for promising semiconductor SBs, which reaches 200 W/kg, and the implementation of the proposed SB does not require scarce materials and complex technologies, since the production of very thin conductive films is a practically mastered process. The cost of creating the proposed SBs should be expected at the level of the cost of putting them into orbit, and since the latter is proportional to the mass of the SBs, the gain in the cost of generating electricity using the proposed SBs becomes quite obvious. In addition, the proposed SBs are characterized by a longer service life and less stringent operational requirements. The proposed SBs allow the possibility of their effective use as control (solar-sail) organs for orientation and correction of the orbit of space objects. Prospects for improving the proposed SB are mainly associated with the creation of very thin conductive films (less than 0.1 μm) and ultralight carrier frames. Relevant research is being carried out in the field of "solar sail" type devices. Sources of information 1. Koltun M.M. Solar cells. M. Science, 1987, pp. 136-154. 2. Grilikhes V.A. and other Solar energy and space flights. M. Science, 1984 str.144 (prototype).

This main indicator of the proposed SB is almost 20 times higher than the same indicator for promising semiconductor SBs, which reaches 200 W/kg, and the implementation of the proposed SB does not require scarce materials and complex technologies, since the production of very thin conductive films is a practically mastered process. The cost of creating the proposed SBs should be expected at the level of the cost of putting them into orbit, and since the latter is proportional to the mass of the SBs, the gain in the cost of generating electricity using the proposed SBs becomes quite obvious. In addition, the proposed SBs are characterized by a longer service life and less stringent operational requirements. The proposed SBs allow the possibility of their effective use as control (solar-sail) organs for orientation and correction of the orbit of space objects. Prospects for improving the proposed SB are mainly associated with the creation of very thin conductive films (less than 0.1 μm) and ultralight carrier frames. Relevant research is being carried out in the field of "solar sail" type devices. Sources of information 1. Koltun M.M. Solar cells. M. Science, 1987, pp. 136-154. 2. Grilikhes V.A. and other Solar energy and space flights. M. Science, 1984 str.144 (prototype).

Batteries and solar panels, solar panels, alternative energy, solar energy

On the first satellites of the Earth, the equipment consumed relatively small current powers and its operation time was very short. Therefore, as the first space energy sources, ordinary accumulators.

As you know, on an airplane or car, the battery is an auxiliary current source and works in conjunction with an electric machine generator, from which it is periodically recharged.

The main advantages of batteries are their high reliability and excellent performance. The main disadvantage of batteries is big weight with low power consumption. For example, a silver-zinc battery with a capacity of 300 Ah weighs about 100 kg. This means that with a current power of 260 watts (normal consumption on a manned satellite "Mercury"), such a battery will work for less than two days. The specific weight of the battery, which characterizes the weight perfection of the current source, will be about 450 kg / kW.

Therefore, the battery as an autonomous current source has been used in space until now only at low power consumption (up to 100 W) with a service life of several tens of hours.

Large automatic satellites of the Earth, saturated with a variety of equipment, required more powerful and lighter current sources with a very long service life - up to several weeks and even months.

Such current sources were purely space generators - semiconductor photovoltaic cells operating on the principle of converting the light energy of solar radiation directly into electricity. These generators are called solar panels .

We have already talked about the power of the thermal radiation of the Sun. Recall that outside the earth's atmosphere, the intensity of solar radiation is quite significant: the flux of energy incident on the surface perpendicular to the sun's rays is 1340 watts per 1 mg. This energy, or rather, the ability of solar radiation to create photoelectric effects, is used in solar batteries. The principle of operation of a silicon solar battery is shown in fig. thirty.

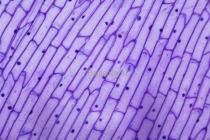

The thin wafer consists of two layers of silicon with different physical properties. Inner layer is pure monocrystalline silicon. Outside it is covered very thin layer"contaminated" silicon, for example, with an admixture of phosphorus. After irradiating such a “wafer” with sunlight, an electron flow occurs between the layers and a potential difference is formed, and an electric current appears in the external circuit connecting the layers.

The thickness of the silicon layer is required to be negligible, but due to the imperfection of the technology, it usually ranges from 0.5 to 1 mm, although only about 2% of the thickness of this layer takes part in the creation of the current. For technological reasons, the surface of one solar battery element turns out to be very small, which requires a large number of elements to be connected in series in a circuit.

A silicon solar battery gives current only when the sun's rays fall on its surface, and the maximum current removal will be when the battery plane is perpendicular to the sun's rays. This means that when moving spaceship or OCS in orbit, a constant orientation of the batteries to the Sun is necessary. Batteries will not provide current in the shade, so they must be used in conjunction with another source of current, such as a battery. The latter will serve not only as a storage device, but also as a damper for possible fluctuations in the amount of energy required.

efficiency solar panels is small, it does not exceed 11-13% so far. This means that from 1 m 2 of modern solar batteries, the power is about 100-130 watts. True, there are opportunities to increase efficiency. solar batteries (theoretically up to 25%) by improving their design and improving the quality of the semiconductor layer. It is proposed, for example, to superimpose two or more batteries one on top of the other so that the lower surface uses that part of the solar energy spectrum that the upper layer passes without absorbing.

efficiency battery depends on the surface temperature of the semiconductor layer. The maximum efficiency is achieved at 25°C, and with an increase in temperature to 300C, the efficiency increases. is almost halved. Solar panels are advantageous to use, as well as batteries, for small current consumption due to their large surface area and high specific gravity. To obtain, for example, a power of 3 kW, a battery is required, consisting of 100,000 cells with a total weight of about 300 kg, i.e. with a specific weight of 100 kg/kW. Such batteries will occupy an area of more than 30 m 2.

Nevertheless, solar batteries have proven themselves in space as a fairly reliable and stable source of energy that can work for a very long time.

The main danger to solar cells in space is cosmic radiation and meteor dust, which cause surface erosion of silicon cells and limit battery life.

For small inhabited stations, this current source will apparently remain the only acceptable and sufficiently efficient one, but large SCSs will require other energy sources, more powerful and with a lower specific gravity. At the same time, it is necessary to take into account the difficulties of obtaining alternating current with the help of solar batteries, which will be required for large scientific space laboratories.

Recently in Colorado there was a conference "A New Generation of Suborbital Explorers", which discussed, in particular, projects for the construction of space solar stations. And if no one took such ideas seriously before, now they are really close to being implemented.

Thus, the US Congress is preparing a plan for the gradual transition of America from fossil fuels to space energy. A specially created department of space will be responsible for the implementation of the project, NASA, the Department of Energy and other organizations will play an active role in its work.

Until October of this year, the Department of Justice must submit to Congress all the necessary changes and additions to the current federal legislation in order to begin construction of space solar power plants. As part of the program, at the initial stage it is planned to develop systems of nuclear space engines to use space shuttles for space logistics and the construction of solar installations in orbit.

Also in active development are technologies that can transform sunlight into electricity and teleport it to Earth.

In particular, specialists from the California Institute of Technology propose to illuminate the planet with the help of orbital "flying carpets". These are systems of 2,500 panels 25 mm thick and 2/3 of a football field long. Elements of such a station will deliver rockets like the Space Launch System, an American super-heavy launch vehicle being developed by NASA, into orbit. The space power station is being created as part of the SSPI (Space Solar Power Initiative), a partnership project between the California Institute of Technology and Northrup Grumman. The latter has invested $17.5 million to develop the core components of the system over the next three years. The initiative was also supported by researchers at NASA's Jet Propulsion Lab.

According to Caltech professor Harry Atwater, who led the Space Solar Power Initiative, "flying carpets" convert solar energy into radio waves and send them to earth. The energy will be transmitted according to the principle of a phased array, which is used in radar systems. This will allow you to create a stream moving in any direction.

Solar panels consist of tiles, 10x10 cm in size and weighing about 0.8 g, which will provide a relatively low cost of launching the structure. Each tile will transmit the converted energy autonomously, and if one of them fails, the rest will continue to work. The loss of a few elements due to solar flares or small meteorites will not harm the power plant. According to the calculations of scientists, with mass production, the cost of electricity from such a source will be less than when using coal or natural gas.

The percentage of ground-based solar installations in the overall balance of energy supply in many countries of the world is becoming higher. But the possibilities of such power plants are limited: at night and with heavy cloud cover, solar panels lose their ability to generate electricity. Therefore, the ideal option is to place solar power plants in orbit where day does not change into night, and clouds do not create barriers between the Sun and the panels. The main advantage of building a power plant in space is its potential efficiency. Solar panels located in space can generate energy ten times more than batteries located on the surface of the Earth.

The idea of orbital power plants has been developed for a long time, scientists from NASA and the Pentagon have been engaged in similar research since the 60s. Previously, the implementation of such projects was hampered by the high cost of transportation, but with the development of technology, space power plants may become a reality in the foreseeable future.

There are already several interesting projects for the construction of solar installations in orbit. In addition to the Space Solar Power Initiative, the Americans are developing an orbital solar panel that will absorb solar radiation and transmit electron beams using radio waves to the earth's receiver. The authors of the development were specialists from the US Navy Research Laboratory. They built a compact solar module with a photovoltaic panel on one side. Inside the panel is electronics that converts direct current into radio frequency for signal transmission, the other side supports an antenna to transmit electron beams to Earth.

According to the lead author of the development, Paul Jaffe, the lower the frequency of the electron beam carrying energy, the more reliable its transfer to bad weather. And with a frequency of 2.45 GHz, you can get energy even during the rainy season. The solar receiver will provide energy for all military operations, diesel generators can be forgotten forever.

The US is not the only country that plans to receive electricity from space. The fierce struggle for traditional energy resources has forced many states to look for alternative energy sources.

The Japanese space exploration agency JAXA has developed a photovoltaic platform for installation in Earth's orbit. The solar energy collected with the help of the installation will be supplied to the receiving stations of the Earth and converted into electricity. Solar energy will be collected at an altitude of 36,000 km.

Such a system, consisting of a series of ground and orbital stations, should start operating as early as 2030, its total capacity will be 1 GW, which is comparable to the standard nuclear power plant. To do this, Japan plans to build an artificial island 3 km long, on which a network of 5 billion antennas will be deployed to convert microwave radio waves into electricity. JAXA researcher Susumi Sasaki, who led the development, is confident that placing solar batteries in space will lead to a revolution in energy, allowing over time to completely abandon traditional energy sources.

China has similar plans, which will build a solar power plant larger than the International Space Station in Earth's orbit. total area solar panels installation will be 5-6 thousand square meters. km. According to experts, such a station will collect the sun's rays 99% of the time, and space solar panels will be able to generate 10 times more electricity per unit area than ground-based counterparts. It is assumed that for transmission to the ground collector, the generated electricity will be converted into microwaves or a laser beam. The start of construction is scheduled for 2030, the cost of the project will be about $1 trillion.

World engineers are evaluating the possibilities of building solar space power plants not only in orbit, but also in areas closer to the Sun, near Mercury. In this case, solar panels will require almost 100 times less. In this case, the receiving devices can be moved from the Earth's surface into the stratosphere, which will allow efficient energy transfer in the millimeter and submillimeter ranges.

Projects of lunar solar power plants are also being developed.

For example, the Japanese company Shimizu proposed to create a belt of solar panels stretched along the entire equator of the Moon for 11 thousand km and a width of 400 km.

It will be placed on the back side of the Earth's satellite so that the system is constantly under the sun's rays. It will be possible to link the panels using conventional power cables or optical systems. The generated electricity is planned to be transmitted using large antennas, and received using special receivers on Earth.

In theory, the project looks great, it remains to figure out how to deliver hundreds of thousands of panels to the Earth’s satellite and install them there, as well as how to deliver energy from the Moon to our planet without losing a significant part of it along the way: after all, you will have to overcome 364 thousand km. So the ideas of creating lunar power plants are too far from reality, and if they are realized, then very slowly.

Tatyana Gromova