Everyone - always sharp and safe work!

ZAT (Dnepr, Ukraine)

March 23, 2020

March 20, 2020

Use this data if you think you have reason to be concerned. And if it turns out that they are, then immediately contact your family doctor for advice:

P.S. Share this spreadsheet with family, loved ones and friends. Perhaps for someone she will clarify incomprehensible issues related to the coronavirus or (if everything is already so bad) will convince you to see a doctor, and not self-medicate ...

March 15, 2020

Created 02/25/20, last update - 02/25/20

March 10, 2020

ZAT (Dnepr, Ukraine)

March 05, 2020

Everyone Have a good day and safe internet!

YouTube...

Photo by Gerd Altmann from Pixabay

ZAT (Dnepr, Ukraine)March 01, 2020

| Temper color chart for carbon steel:* | |

| Bright yellow | 1100°C |

| Dark yellow | 1040°C |

| orange yellow | 980°C |

| Orange | 930°C |

| red-orange | 870°C |

| bright red | 820°C |

| Red | 760°C |

| dull red | 650°C |

| Reddish with a gray tint | 590°C |

| Gray with a red tint | 540°C |

| Dark grey | 430°C |

| Grey-blue | 320°C |

| Light blue | 310°C |

| Blue | 300°C |

| Dark purple | 280°C |

| Violet | 270°C |

| Brown purple | 260°C |

| Brown | 250°C |

| Light brown | 240°C |

| golden yellow | 230°C |

| Light yellow | 220°C |

| Straw | 210°C |

| Light straw | 200°C |

* Depending on the composition and thermal conductivity of the steel, the temperature values for individual tint colors may differ slightly from those given in the table.

You should also remember that:

1. The tint of the tint is affected by the heating rate of the steel, the exposure time, lighting, the presence of traces of oil or chemicals, reagents, air or gaseous media, etc.

2. For alloy steels and stainless steels that are more resistant to air oxidation, tint colors begin to be noticeable at higher temperatures.

3. The thickness of the oxide film increases with increasing heating time - this should be taken into account if the tool or part is subjected to constant or intermittent heating. Therefore, steel that has been kept for a long time (with constant or intermittent heating) at a temperature of 200 ° C may turn brown or purple. Although at the same time the temperature of its heating never exceeded the one necessary to obtain a light straw color of tint.

4. Increasing the thickness of the oxide film may cause malfunction of the hinged instruments.

That's all for now.

Sources: wikipedia.org, threeplanes.net, avventurosamente.it

P.S. Don't forget to subscribe to my channel YouTube...

Created on 27.09.10, last update - 25.02.20

Created on 10/03/10, last updated on 02/28/20

February 25, 2020

P.S.1. The Sharpening Blog previously published an article "". Read it, it's interesting and resonates with the topic of today's article.

P.S.2. Subscribe to my channel at YouTube...

February 20, 2020

Which sterilizer to choose for manicure and pedicure tools? How to choose dry heat or autoclave? I am sure that this article and comments to it will help the reader to make this difficult choice. If you did not find the answer to your question, then ask it in the comments (do not forget to introduce yourself who you are and where you are from)...

Sterilization is carried out in order to destroy all pathogenic and non-pathogenic organisms and spore forms - after it, microbes can be found only on one of a million infected instruments, while after disinfection - on five, ten, a hundred or more.

In manicure parlors, hairdressers and beauty salons, physical (steam, air, heated glass beads) and chemical (chemical solutions) methods are usually used for sterilization. The need for sterilization is governed by state, national and local laws, rules and regulations, which can and should be applied, but which may differ in different countries. Below, all the above methods of sterilization, more or less common in the beauty industry, are considered in detail.

AIR STERILIZER

Each of the developed steel grades is designed to solve a certain class technical tasks. It has its own chemical composition, has certain mechanical properties. For example, steel 40x13 belongs to the category of corrosion-resistant stainless heat-resistant martensitic steels. Sometimes in everyday life it is called "knife". She and her counterparts have similar characteristics. They have good mechanical properties mi, high resistance to corrosion (even in slightly aggressive environments). These specific properties determine the scope of its application.

It is available in the following products:

- rolled sheet (of various thicknesses);

- tape (of various widths);

- predetermined long products;

- wire of various thicknesses.

Composition and properties

The composition of steel grade 40x13, in addition to the main components, includes the following chemical elements: chromium (14%), carbon (does not exceed 0.45%), the remaining elements silicon and others account for no more than 0.8%, which corresponds to GOST 5582-75.

Download GOST 5582-75

Chemical composition of steel

The main chemical elements that make up the composition are: iron, carbon, silicon, manganese, chromium, sulfur and phosphorus. The percentage of carbon content in this steel (depending on the release) varies in the range of 0.36-0.45%. This steel belongs to the class of medium carbon.

The chemical microstructure in the hardened state includes martensites, carbides and a residual austenite content. It is these elements that provide good corrosion resistance. Higher rates are inherent only in stainless steel grade 30x13.

Mechanical properties

The mechanical properties of steel 40x13 are determined by its composition and processing method. After a special softening treatment and subsequent tempering at a temperature of about 740 degrees, it is possible to increase the tensile strength and reach a value of 560 MPa. This treatment allows to achieve a relative elongation of more than 15%, which is very important for further machining. If this is hot-rolled steel with subsequent forging and calibration, then its hardness reaches 229 HB. After the hardening procedure, the Rockwell hardness exceeds 55 HRC units. The density of this steel grade is 7.68 g/cm 3 .

After successive hardening and gradual low tempering, this steel grade acquires good anti-corrosion properties. The only limitation in this area is long-term use in seaside atmospheres or in salty sea water.

Based on the physical properties, brand 40x13 can be attributed to the class of tool steels.

Application area

Due to its characteristic properties, 40x13 steel is used in such industries as:

- aviation;

- mechanical engineering (including automotive industry);

- metalworking;

- production equipment for the food industry;

- medicine;

- manufacture of household appliances and devices.

In the production of helicopters and aircraft, individual elements of the fuselage structure are made from it.

In mechanical engineering and automotive industry, it is used for the manufacture of: shafts, various bushings, housings, turbine blades, needles for carburetors of automobile engines, springs, bearings. It is actively used for the production of a wide variety of hardware products (bolts and nuts). In addition, this steel grade is used in the manufacture of measuring tools, products designed to work in slightly aggressive environments at low temperatures (not higher than 450 ° C).

It occupies a special place in the production of household and medical cutting instruments. When carrying out high-quality hardening, good knives and scalpels are obtained from steel 40x13. Therefore, it was called medical steel. In this case, the hardness of these tools on the Rockwell scale can reach 58 HRC units. These tools lend themselves well to sharpening, they practically do not rust and do not require additional care.

In addition to these properties, it is noted that this brand of metal is absolutely non-flake sensitive.

Processing methods

The considered steel is subjected to two main types of processing: thermal and mechanical. Heat treatment of steel 40x13 is used to give it the appropriate technological properties. Mechanical - to create the required shape, solve the set technical problems.

Experts refer such metal to the category of materials that, when carrying out heat treatment require a specific approach. It is this type of processing that gives the required properties.

The main types of heat treatment are:

- sequential hardening;

- slow release after heating;

- hot and cold plastic deformation;

- annealing.

After quenching, the following components are formed in the structure:

- carbides;

- martensites;

- some remnants of so-called austenites.

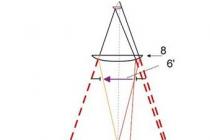

The first two processing methods make it possible to give the steel good corrosion resistance and excellent mechanical properties. This is possible due to the fact that it has good plastic deformation. Such steel is hardened by gradual heating to a temperature of more than 950 °C, but not more than 1100 °C. Sequential heating is necessary because this steel grade has an increased sensitivity to cracks. To avoid manifestation negative consequences a metal part (especially with a thickness of more than 100 millimeters, it is necessary to heat up for more than 10 minutes).

To avoid the appearance of cracks, including in the depth of the metal, the sample is subjected to the so-called tempering. That is, a gradual decrease in temperature and keeping the sample at temperatures up to 300 °C. In this case, the steel acquires its maximum strength characteristics. If the temperature regime is not maintained, and the process takes place at 450 ° C, the steel will lose its impact strength characteristics. It acquires the best corrosion properties and good ductility if the following parameters are observed. Sequential heating to a temperature of 700 °C, subsequent exposure for 20 minutes, cooling in a container with oil.

As a softening heat treatment, the so-called annealing is used. The part is heated to a temperature of 800 °C. Next, slow cooling is carried out in the furnace itself to a temperature of about 500 ° C.

As an alternative to the standard type of heating, high frequency heating is used for heat treatment. Especially this method is used when it is necessary to harden the surface layer of the part. These are parts that are included in mechanisms with friction and rolling units, in elements pipe fittings. Typically, such hardening is applied only to parts whose thickness exceeds 15 millimeters. With its help, it is possible to achieve a hardness index after hardening equal to 36.5 HRC units.

The above reasoning proves that the steel grade 40x13 is quite critical to the rules for observing the conditions of heat treatment.

It is subjected to the following types of machining:

- drilling holes;

- sharpening;

- milling;

- forging.

Carrying out these operations is associated with certain difficulties:

- Hardening of the surface layer (this is due to additional heating of the workpiece at the time of cutting or drilling).

- Problems with the disposal of metalworking waste (the resulting metal chips form a narrow twisted strip in length). This causes some inconvenience during long-term processing. This problem is solved by installing special devices for metal cutting tools. They produce intermittent chip breaking.

- Increased cutting edge wear. This is due to an increase in the temperature of the part at the point of contact with the edge of the cutting tool. In this case, the presence of crystalline compounds (carbides and martensites) in this grade creates the effect of the presence of abrasive elements in it, which leads to rapid wear of the cutting edge.

In addition, difficulties arise when sharpening cutting tools made from this steel. At the moment of sharpening, the temperature of the edge being sharpened rises and a so-called metal influx is formed. This leads to uneven hardening of the edge of the surface to be sharpened.

Forging, as mechanical processing, is carried out only when the part is heated to a temperature of 1250 ° C. During the forging process, the temperature may drop below 850 °C.

After this operation (hot deformation), only slow cooling followed by low-temperature annealing is allowed.

Unfortunately, welding is not included in the available list of machining. The fact is that this brand of metal belongs to the category of difficult-to-weld materials. Therefore, this processing method is not used to connect structures made of this material.

Existing analogues

All developed countries are engaged in the production of steel with similar properties. In different countries, it has its own marking:

- in the USA it is steel, which is marked AISI 420;

- in Germany, the analogues of our steel is a whole line (from X38Cr13 to X46Cr13);

- China produces steel under the 4S13 brand;

- in Japan it is SUS 420J2;

- in France, there is also a whole line with similar characteristics. These are X40Cr14, Z33C13, Z38C13M, Z40C13, Z40C14, Z44C14, Z50C14.

All these analogues have good anti-corrosion performance. They can long time withstand exposure to such mildly aggressive liquids as spirits, wine and even cognac spirit.

"Hard-worked, heat-treated, polished bars from high-alloy and corrosion-resistant steel. Specifications.";

GOST 5582-75 "Corrosion-resistant, heat-resistant and heat-resistant thin-sheet rolled products. Specifications";

GOST 5632-72 "High-alloy steels and corrosion-resistant, heat-resistant and heat-resistant alloys. Grades";

GOST 5949-75 "Steel and calibrated corrosion-resistant, heat-resistant and heat-resistant. Specifications";

TU 14-1-2186-77;

GOST 4405-75

GOST 14955-77 "Quality round steel with special surface finish. Specifications.";

GOST 2590-2006 "Steel hot-rolled round bars. Assortment.";

GOST 2591-2006 "Hot-rolled square section steel. Assortment.";

GOST 7417-75 "Sizing round steel. Assortment.";

GOST 4405-75 "Hot-rolled and forged strips from tool steel. Assortment.";

GOST 8559-75 "Square calibrated steel. Assortment.";

GOST 8560-78 "Calibrated hexagonal rolled stock. Assortment.";

GOST 1133-71 "Round and square forged steel. Assortment.";

GOST 5632-72 "High-alloy steels and corrosion-resistant, heat-resistant and heat-resistant steels. Grades.";

GOST 103-2006 "Rolled section steel hot-rolled strip. Assortment.";

GOST 5949-75 "Steel and calibrated corrosion-resistant, heat-resistant and heat-resistant. Specifications.";

GOST 2879-2006 "Hot-rolled hexagonal section steel. Assortment.";

TU 14-11-245-88 "Shaped steel profiles high precision. Specifications.";

OST 3-1686-90 "Structural steel blanks for mechanical engineering. General specifications.";

The chemical composition of steel 40X13

| C | Cr | Fe | Mn | P | S | Si |

| 0,36-0,45 | 12-14,0 | Main | ≤0,8 | ≤0,030 | ≤0,025 | ≤0,8 |

Mechanical properties of steel 40X13

Normalized mechanical properties at 20 °C

GOST | Product type | Heat treatment mode | σ in , N/mm² | δ5, % | |||

Sheet thin | |||||||

Grade Ø, ¤ up to 200 mm Calibrated steel | Annealing or tempering | ||||||

Hardening: from 950-1050°C; from 1000-1050 °C, cooling in oil; tempering at 200-300°С, cooling in air or in oil | |||||||

Tape δ = 0.2-2 mm | Annealing or tempering at 740-800 °C | ||||||

δ < 0,2 мм | |||||||

Mechanical properties at elevated temperatures

t test, °С | σ in , N/mm² | σ 0.2 , N/mm² | δ5, % | KCU, J / cm 2 | t test, ° С | σ in , N/mm² | σ 0.2 , N/mm² | δ5, % | KCU, J / cm 2 |

||

Steel 30X13 (quenching from 1000°C in air, tempering at 650°C) | Steel 40X13 (hardening from 1050 °C in air, tempering at 600 °C, hardness 311-331 HB) |

||||||||||

Steel 40X13 (quenching from 1050 °C in air, tempering at 650 °C, hardness 277-286 HB) |

|||||||||||

Physical properties of steel 40X13

Physical properties

Corrosion resistance of steel 40X13

Steels 30X13 and 40X13 have the best corrosion resistance after hardening from a temperature that ensures complete dissolution of carbides. An increase in tempering temperature is accompanied by a decrease in their resistance to general corrosion. The reason for the decrease in corrosion resistance is the depletion of the solid solution in chromium due to the precipitation of chromium carbides. At the same time, the corrosion resistance of 40X13 steel is somewhat lower than that of 30X13 steel. A decrease in corrosion resistance is observed when tempering up to 600°C, then some increase occurs. However, corrosion resistance does not reach the level that both steels have in the hardened or low-stressed state.Thus, it is advisable to use steels 30X13 and 40X13 either after thermal tempering at 200–400°C (in order to obtain high hardness and corrosion resistance), or after high tempering at 600–650°C in order to obtain a structural material.

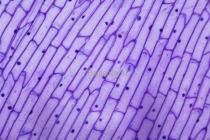

Structure of steel 40X13

In the hardened state, the microstructure consists of martensite and carbides and a small amount of retained austenite. When heated above the temperature A c3, the structure consists of austenite and chromium carbides of the M 23 C 6 type. Starting from a hardening temperature of 1050 °C and higher, the hardness of steel (30X13) does not increase and even tends to decrease, which indicates an increase in the amount of residual austenite.The tempering of both grades of hardened steel leads to the decomposition of martensite into a ferrite-carbide mixture and to a decrease in hardness. However, in the tempering temperature range of 450–550°C, the effect of secondary hardness is observed, associated with the precipitation of dispersed carbides.

Critical points for both steels: A c1 = 820 °С; A c3 \u003d 860-880 ° С; МН = 270 °С; MK = 80 °С.

Technological parameters 40X13

Steels 30X13 and 40X13 are well exposed to hot plastic deformation, which is carried out in the range of 1100-850 °C. Steels are prone to cracking fast speeds heating and cooling. In this regard, when heated for hot deformation, slow heating up to 830 ° C is used, and after deformation, slow cooling in a foot, sand or furnace. Cold plastic deformation of steels is limited, especially steel 40X13. As a softening heat treatment after hot deformation, intermediate annealing at 740–800 °C or complete annealing at 810–880 °C is used, followed by slow cooling at 25–50 °C/h to 600 °C. After cold plastic deformation - annealing at 750 °C.The final heat treatment is quenching from 950-1050 °C with cooling in oil or air and tempering to a given hardness and corrosion resistance. For steels used for the manufacture of surgical instruments, stepwise hardening from 1020-1040 °C is recommended, followed by cooling in alkali at 350 °C in order to reduce warpage and improve elastic properties.

© The use of materials from the site is possible only with the permission of LLC "LASMET"

One of the most sought-after materials in the field human activity is steel. An alloy of iron and carbon has unique technical characteristics, thanks to which the versatility of this material is ensured. And among the best are specifications 40x13 steel, which is why it is used in a fairly large number of production processes.

Steel marking

In order to understand the characteristics inherent in the presented material, it is necessary to understand what its marking means. There is in the world a large number of steels, all differ in their properties. And every day a new brand of material can be produced. Therefore, you should understand the abbreviation of the product.

Steel 40x13 is alloyed, that is, in addition to carbon and iron, it contains other active elements. In this case, chromium is contained: this is indicated by the letter X in the marking. Its percentage is 1.3 percent. But the technical characteristics of steel 40x13 depend mainly on the amount of carbon contained in it. In this case, the material contains 0.40 percent of element with serial number 6.

Alloy steel production

Alloy steel production technology includes several stages, which are mainly performed in electric arc furnaces:

- Purification of iron ore.

- Steel smelting.

- Introduction of additional additives.

First of all iron ore purify: get rid of foreign components, mainly sulfur, phosphorus. This process is carried out in open melting furnaces using out-of-furnace technology. The refining process is the removal of arsenic and non-ferrous metal impurities from the composition. It is carried out by means of vacuum melting.

The next stage in the manufacture of an alloyed steel grade consists directly in the smelting of a steel product. To do this, the raw material in an electric arc furnace is heated to a temperature of 400 to 600 degrees. During melting, iron turns into cast iron, which has an unstable crystal lattice. Through its stabilization, steel is obtained.

The next stage in the manufacture of an alloyed steel grade consists directly in the smelting of a steel product. To do this, the raw material in an electric arc furnace is heated to a temperature of 400 to 600 degrees. During melting, iron turns into cast iron, which has an unstable crystal lattice. Through its stabilization, steel is obtained.

To do this, oxygen is supplied to the chamber, which, when burned, releases carbon into the atmosphere of the furnace. It, mixing with iron, converts cast iron into steel. After that, heterogeneous additives (in our case, chromium) are added to the raw materials. As a result, the crystal lattice of metal products becomes even more compacted, and an alloyed product is obtained.

Specifications

Following the smelting of the alloyed steel grade, the process of quenching and tempering the sample follows. Hardening of the sample is carried out at a temperature of 1100 degrees. After this, it is important to observe gradual tempering, otherwise the sample will be covered with cracks. To prevent this, this event is held at a temperature of 600 degrees.

Thanks to this manufacturing process, the final product has the following technical characteristics:

Thanks to this manufacturing process, the final product has the following technical characteristics:

- Temporary tensile strength - 1140 MPa.

- The conditional yield strength at residual deformation is 910 MPa.

- Relative elongation - 12.5 percent per five times the length of the sample.

- Impact strength - 12 J /.

These characteristics allow the material to be used in various fields human activity.

Application

In industry, steel 40x13 has been widely used. It is mainly used in environments with high humidity. The chromium contained in it enhances the anti-corrosion properties obtained from conventional hardening.

The presented brand has good performance plasticity: at a temperature of more than 1000 degrees, it is easily deformable. This material is actively used in the production of cutting and measuring tools, household items.

The presented brand has good performance plasticity: at a temperature of more than 1000 degrees, it is easily deformable. This material is actively used in the production of cutting and measuring tools, household items.

The characteristics of steel 40x13 made it possible to use it in the manufacture of machine parts, mainly bearings and compressor parts. The main condition for the use of finished elements is that the temperature of the working environment should not exceed 400 degrees. In construction, the material is practically not used, because it is not welded.

Anti-corrosion performance and their impact on the use of steel

Steel 40x13 GOST has distinctive indicators of corrosion resistance. It is achieved by hardening the product from a temperature at which complete dissolution of carbides is ensured. But, if the tempering temperature is increased after heat treatment, there will be a decrease in corrosion resistance due to the volatilization of chromium from the material. A decrease in parameters occurs at a release temperature above 600 degrees.

As a result, in order to obtain more favorable technical characteristics of steel 40x13, it must be tempered at temperatures from 200 to 300 degrees in order to obtain high hardness and corrosion resistance, or at a temperature of 600-650 units Celsius - to convert the product into structural steel .

Any steel has certain properties that are unique to a particular brand. And metallurgists are trying to make every effort to obtain the highest and highest quality characteristics of the material. But, since it is not entirely realistic to obtain an ideal steel structure, it all comes down to the selection of optimal opportunities for certain purposes. After all, everyone knows that a knife made of mild steel is sharpened more easily than one that is made of a more rigid one. And solid steel, on the contrary, is highly resistant to mechanical stress.

With a complex chemical composition, it also slows down manufacturing process steel production, which is why the cost finished product is growing.

The quality of a knife may not always depend on a specific steel grade. plays a big role here high-quality heat treatment of the product. The most popular steel for the manufacture of knives is steel 40x13. It has all the necessary properties and characteristics.

What are the characteristics of steel 40x13

Steel grade 40x13 has the following characteristics:

Steel acquires its anti-corrosion features due to a complex technological process, which involves special hardening. As a result of this procedure, complete dissolution of the carbide, which provides anti-corrosion protection of the material. One of the reasons for the decrease in resistance to corrosion development is the reduced content of chromium in the carbide or the decrease in the melting point of steel to 600 degrees. But if technological process provided correctly, this should not happen.

Steel is smelted in special open-type furnaces. Induction furnaces can also be used for this. Process steel melting is carried out at a temperature of 850 to 1100 degrees, which ensures its complete deformation. To avoid cracks, the technological procedure provides for special heating and cooling modes, which are carried out alternately.

Constituent elements after hardening

After the steel has passed the quenching procedure, its components are the following elements:

After reaching the temperature limit of 1050 degrees and above, a decrease in the hardness of the material is observed. This indicates an increase in the amount of austenite in the steel composition. When the melting temperature drops to 450-550 degrees there is a secondary hardness of the material, which occurs as a result of the release of finely dispersed carbide from the steel composition.

Scope of steel 40x13

Steel grade 40x13 is widely used for the manufacture of inexpensive domestic kitchen knives. Products made of this steel are perfect for household use, as they do not rust under any circumstances, are easy to sharpen and are easy to use and maintain. With a knife with such steel, you can easily cut all types of gastronomic products, meat, fish, vegetables and fruits. Such a blade is not only sharp enough, but also completely safe for food use.

Steel grade 40x13 is widely used for the manufacture of inexpensive domestic kitchen knives. Products made of this steel are perfect for household use, as they do not rust under any circumstances, are easy to sharpen and are easy to use and maintain. With a knife with such steel, you can easily cut all types of gastronomic products, meat, fish, vegetables and fruits. Such a blade is not only sharp enough, but also completely safe for food use.

Besides, steel 40x13 is used for the production of medical scalpels and other tools. Measuring devices, springs, bearings, compressor elements and other items that are applicable in the household are made from it.

The only disadvantage of products made from such steel is such a factor as instability to aggressive environments and high temperature conditions. Therefore, this type of steel is forbidden to be used for welding.

What reviews do steel products 40x13 use

Products made of steel 40x13 are in great demand among a wide range of consumers. Therefore, the production of this steel grade occupies an important place in metallurgy. Many note that knives made of such material very durable due to its hardness. The blades sharpen well and stay sharp for a long time. In addition, steel is not susceptible to corrosion, which further increases its demand in the market. Moreover, products made from it have an acceptable cost compared to its other counterparts.

Products made of steel 40x13 are in great demand among a wide range of consumers. Therefore, the production of this steel grade occupies an important place in metallurgy. Many note that knives made of such material very durable due to its hardness. The blades sharpen well and stay sharp for a long time. In addition, steel is not susceptible to corrosion, which further increases its demand in the market. Moreover, products made from it have an acceptable cost compared to its other counterparts.

Particularly fond of steel 40x13 are divers, fishermen, divers and just housewives. After all, knives produced from this steel are really practical for use in various industries. Souvenir blades are also successfully produced from it.

It is worth noting that products made of steel material do not require any special care at all, except for sharpening. But with steel 40x13 careful handling is required because the blades of the knives are very flexible. For example, you can not use such a knife to work with hard surfaces.

Especially popular is a manicure tool made of a material such as steel 40x13. Due to their hardness, the tweezers handle the cuticle well. In this case, do not sharpen the tool often. And its constant use does not lead to deformation of the product.

Particularly pleased with the quality of the blades and medical workers in particular surgeons. After all scalpels are made mainly of steel 40x13. It even acquired a new name - medical steel.

Particularly pleased with the quality of the blades and medical workers in particular surgeons. After all scalpels are made mainly of steel 40x13. It even acquired a new name - medical steel.

When purchasing products made of steel 40x13, you must remember that you need to treat things carefully. Knife blades do not like to be stored in damp and very humid conditions. Small dots of rust may appear on them, which, of course, will disappear after sharpening. But, it is better to avoid such oversights.

I have been using a 40x13 steel kitchen knife for several years now. And I want to say that a knife made of such material is quite durable and easy to use. It is good and easy to sharpen. Perfectly cuts even tough meat and fish. Its durability is amazing. The blade did not wear off at all during its constant use.

Elena, Orel

I have been a nail technician for 10 years. In my work, I had to use various cutting tools to give the nails the desired shape and neat appearance. I was especially pleased with the tweezers for trimming the cuticles, made of steel 40x13. The material is quite durable, remains sharp for a long time, does not deform when sharpened.

Svetlana, Yekaterinburg

On the market they offered to buy a bearing for a bicycle made of steel 40x13. Was very satisfied. Turned out to be pretty solid and good quality. Highly recommend!