PLASTIC- the property of solids to change shape and size under the influence of external loads and retain it when the loads cease to act (after the loads are removed).

The first idea about the property of the material, called plasticity, gives a lump of plasticine, which easily changes shape under the pressure of the fingers, and retains new form after acting on it (as opposed to a stretched spring, which will shrink again if it is released. In this sense, they say that the spring is elastic, and plasticine is plastic. Plasticine and plasticity are words of the same root, from the Greek word plastic, which means modeling, from the verb "sculpt" (from clay).

To get a more accurate idea of the plasticity property, you can do (or imagine) a simple experiment. Let there be an elongated plasticine parallelepiped (rod) whose long edge is approximately 10 cm, and the small face is a square 1 cm × 1 cm. Let this rod rest on two supports (“bridge”) with its ends. If metal weights (for example, coins) are placed on the middle of the rod, then while the load is small, the change in the shape of the rod is imperceptible to the eye. With further loading, it is found that at some point the rod bends and becomes curvilinear. If you remove all the weights, the curvilinear shape will still be preserved.

This experience shows that a rod made of a material with the property of plasticity resists the action of loads, almost without changing its shape, until the load exceeds a certain threshold, after which a noticeable change in shape occurs, which persists even after the load is removed. This is the essence of plasticity, but not all - the change in shape (deformation) depends only on the applied load and does not change by itself over time. If deformation at a constant load still occurs, then the material is called not plastic, but viscoplastic or viscoelastic ( cm. RHEOLOGY; CREEP). Of course, plasticine is a familiar and obvious example of a plastic material. It is important that the property of plasticity is inherent in very many structural materials. First of all, these are metals and alloys - steel, iron, copper, aluminum and others, but the idea of plastic deformation is also very useful for understanding the processes of deformation of composite materials, including metal-ceramic, carbon and polymer.

The plasticity of the material is, as it were, opposed to elasticity: the plastic body retains the shape given to it, and the elastic one restores the original one. But plasticity is also opposed to brittleness: a plastic body responds to an increase in load by a noticeable change in shape, and a brittle one (for example, glass) - by the appearance of cracks and destruction.

The study of plasticity is developing in two directions: one of them is connected, first of all, with the problems of technology and its purpose is to answer the question: if the structure is subjected to external forces of a known magnitude, what is the change in shape - i.e. how is it deformed? It is important for a designer to know this, but there is another important circumstance: plasticity usually precedes failure, so the study of plastic deformations is the basis for predicting the strength and durability of a structure.

The second direction in the study of plasticity is the study of what happens in the material, as they say, at the micro level, i.e., what happens inside the material, for example, during plastic bending of a beam. It is possible, by analogy with the experiment on the bending of the rod, to make an experiment on its tension: the upper end of the rod (it is usually called a sample) is fixed, and a load is applied to the lower end. In this case, it is difficult to notice a change in the length of the sample by eye, but if the deformations are measured with special devices, it is found that the deformation process turns out to be similar to that in the experiment with bending: with a gradual increase in the tensile load, very small elastic deformations first appear, when the load reaches the threshold value, then the deformations (now, mostly plastic) become, firstly, more significant, and, secondly, irreversible (i.e., they do not disappear after the load is removed).

In this case, interesting phenomena are revealed. If a steel sample in the form of a long plate with a polished (mirror) surface is used in a tensile test, then in the process of plastic deformation, many close thin parallel straight lines appear on this surface, oriented at an angle of 45 ° to the sample axis (the axis of the sample is a straight line here). passing in the middle of the plate, parallel to its long sides). These lines are called the Luders-Chernov lines (after the names of the scientists who discovered them).

Microscopic analysis of these lines shows that they appear as a result of shearing in the plate material, i.e. one thin layer as if shifted relative to the second, the second - relative to the third, etc., like cards in a deck. It can be said that the Luders-Chernov lines are the boundaries of the shearing layers. Figure 1 schematically shows the picture of such deformation. This scheme makes it possible to understand how such shifts lead to plastic elongation of the sample and why plastic deformations do not disappear after the load is removed. More complex and precise experiments have shown that plastic deformations of metals and alloys are always caused by shifts within the material. In addition, deformations occur in porous materials, in external manifestations very similar to plastic ones, but associated with a decrease in pores. The most familiar porous material is foam; in technology, porous materials are created by powder metallurgy, where parts are pressed from metal powder.

It is possible to quite accurately describe the picture of deformation, considering that the elastic deformations of a body are the result of a change in the distance between the atoms of which it consists, and plastic deformations are the result of shifts.

So, plasticity is the result of shifts. How do shifts happen? This question (and many others) is answered by branches of physics: solid state physics, dislocation theory, metal physics, etc.

These are the two directions in which plasticity is studied, the first is called phenomenological - it studies the phenomenon of plasticity as it can be observed in experiments with samples and loads, and does not rely on the results of microscopic experiments. The phenomenological study of the plasticity of metals begins with the classical tensile test. Its results are presented in the form of graphs (Fig. 2), where the stress s is plotted along the vertical axis, equal to the tensile force P, referred to the cross-sectional area of the sample F, i.e.

s= P/F

and horizontally - deformation of the sample e, equal to elongation d l sample (under the action of force P) divided by its original length l.

e=d l/l

On fig. 2 shows a graph that is called the "stretch curve"; material - one of the steel grades. At the beginning of loading (on the graph from the point O to the point A) stress and strain are proportional, i.e. Hooke's law holds. The coefficient of proportionality is called the modulus of elasticity (or Young's modulus) E. Dot A on the graph is called the elastic limit - after it, the proportionality inherent in elasticity is replaced by a curvilinear dependence, and now the deformation grows much faster than the stress. If at some point B we begin to reduce the voltage (this is called unloading), then on the graph we get a curve that differs little from a straight line - BC down arrow. If, after bringing the voltage to zero, increase it again, the curve will appear on the graph CB 1 (with an arrow up), and then this curve will smoothly turn into the curve B 1D, which would be obtained by deforming the sample without unloading. For simplicity, usually both curves, BC And CB 1, replace with a straight line B 2C, which is parallel to the segment OA.

There are several versions of the theory of plasticity, which differ, on the one hand, in how accurately they take into account the real features of the process of deformation of an elastic-plastic material, and, on the other hand, in the mathematical apparatus used. Some theories are less accurate, but simpler and more convenient for calculations, which is very important, since the calculation of plastic deformations in bodies of complex shape is a very difficult task even with the use of modern computers. Other theories could provide high precision, but lead to very great difficulties, both mathematical and experimental. Apparently, the creation of an "ideal" theory that combines physical clarity, mathematical simplicity and at the same time provides an adequate description of plastic deformation processes is a matter of the future. But even "simple" theories of plasticity are actually quite complex, since they require knowledge and understanding of many experimental results and serious mathematical training. As an example, consider the idea of the simplest theory of plasticity.

In the very simple case tensile test of the sample, the process of elastic deformation is described by Hooke's law

There is no proportionality beyond the elastic limit, but the experimental stretching curve can be described if we assume that the elastic modulus E in this case, it ceases to be a constant value and becomes a function of deformation, i.e.

In these formulas, a new function w = w(e) appears, which is called the plasticity function and must be found from experimental data.

It can be seen that the function w(e) is identically equal to zero under elastic deformations and increases under plastic ones. Then it is clear that both elastic and plastic deformations are described by an equation that generalizes Hooke's law

s= E e

This equation describes the strain curve from which it is essentially derived, and this is so, as long as we are talking only about the tensile test. But the theory of plasticity should “be able to” describe any deformation processes - for example, both torsion, and bending, and their joint manifestation, and for this the formula must be significantly generalized and formulate similar in essence, but immeasurably more complex relationships that would connect the six components of the tensor strains with six stress tensor components. This is where the difficulties begin.

The classical deformation theory is called "the theory of small elastoplastic deformations". This theory is based on three experimental facts:

1. At various elastoplastic deformations at each point of the body, there is a universal functional relationship between the rms value of shear strains and the same rms value of shear stresses.

2. During elastoplastic deformation of a material, the change in volume always occurs elastically.

3. The first two statements are valid only under the condition that all external forces acting on the body increase in proportion to each other (more precisely, in proportion to one parameter, for example, time). This is the so-called "simple" or "proportional" loading.

To properly understand these three statements, the following must be taken into account:

The theory of plasticity, like all empirical theories, is essentially an approximate theory. This means that under certain conditions, when it can describe physical reality (“applicability conditions”), the empirical theory describes this reality with a relatively small but always present error (in other words, with a small error).

The theory of plasticity, about which in question, can give an answer with an error close to 10%. And almost always such an error turns out to be quite acceptable - they say that "the theory works well."

Mathematical formulation of the theory: let there be a strain tensor e ij and stress tensor s ij. It is required to write formulas (relations) that connect these tensors under small elastic-plastic deformations, just as Hooke's law connects them under elastic deformations.

Taking into account the various patterns of volume and shear deformation, we can divide tensors into volume (spherical) and shear (deviator) parts:

e ij= 1/3 Qd ij+e ij

The next step is to establish a connection between shear stresses and deformations, since plasticity is shear.

For the strain deviator, the root-mean-square shift at a given point is determined by the formula

Similarly, the rms shear stress is given by:

This is the universal functional relationship between and , and it is universal in the sense that it takes place at any point of the body and for any type of deformation (bending, torsion, their combination, etc.). The function is considered to be known, but in fact it must be found from processing the results of the experiment. Since, by virtue of universality, it is always the same, in particular, in any experiment, it is convenient to use the tube torsion experiment, from which this function is determined especially easily.

Within the limits of elasticity, and the relationship between

Experiments have shown that the Genka-Ilyushin equations underlying the plasticity model describe the process of monotonic loading quite well. With such a process, at all stages of loading (by external forces, temperatures, etc.), the stress intensity increases all the time.

Monotonic loading is usually realized under simple loading, when all external force factors change in proportion to one increasing parameter. With simple loading, the ratio between external loads remains unchanged during loading. If the unloading process occurs, when the stress intensity decreases at all points of the body (for example, when external forces are removed), then the increment (decrease) of stresses and strains at the unloading stage is determined on the basis of the elasticity equations (unloading law; see Fig. 5.15). The main limitations of the plasticity model under consideration are related to the fact that the plasticity equations refer to the end point of the process and therefore do not take into account the loading history.

If it is clear from the physical relations that monotonic loading takes place, then this disadvantage is insignificant.

Within the framework of the applied plasticity model, the actual loading history can be taken into account if loading is considered as a combination of several stages. If unloading occurs at any intermediate stage, then the calculation is carried out using the elasticity equations.

Rice. 5.15. The process of unloading during elastic-plastic deformation

Other models of plasticity.

More perfect, but also much more complex, is the plasticity model based on the theory of plastic flow by Saint-Venant, Misesat Prandtl and Reiss. In accordance with this theory, the increments of elastic and plasticity deformations are considered separately:

The plastic strain increment is taken as the proportional components of the stress deviator:

where is the increment of stress intensity. The function is determined on the basis of experimental data when the samples are stretched.

The presentation of the theory of plastic flow and other models of plasticity can be found in the specialized literature.

Essay

by discipline:

"Technology of structural materials"

"Physical foundations of plasticity and strength of metals"

Is done by a student

Checked by teacher

Introduction

The main mechanical properties are strength, plasticity, elasticity, viscosity, hardness.

Knowing mechanical properties, the designer, when designing, reasonably selects the appropriate material that ensures the reliability and durability of machines and structures with their minimum weight.

Plasticity and strength are the most important properties solid bodies.

Both of these properties, mutually related to each other, determine the ability of solids to resist irreversible shaping and macroscopic destruction, i.e., the separation of the body into parts as a result of microscopic cracks arising in it under the influence of external or internal force fields.

For the technologist, plasticity is very important, which determines the possibility of manufacturing products by various pressure treatment methods based on the plastic deformation of the metal.

Materials with increased plasticity are less sensitive to stress concentrators and other embrittlement factors.

In terms of strength, ductility, etc., a comparative assessment is made various metals and alloys, as well as their quality control in the manufacture of products.

In physics and technology, plasticity is the ability of a material to receive residual deformations without destruction and to maintain them after the load is removed.

The property of plasticity is crucial for such technological operations like punching, drawing, drawing, bending, etc.

The strength of solids, in a broad sense, is the property of solids to resist destruction (separation into parts), as well as irreversible change in shape (plastic deformation) under the influence of external loads. In a narrow sense - resistance to destruction.

The purpose of this work is to study the physical foundations of plasticity and strength of metals.

1. Physical foundations of the strength of metals

Strength is a fundamental property of solid bodies. It determines the ability of a body to resist without destruction the action of external forces. Ultimately, as is known, strength is determined by the magnitude and nature of the interatomic bond, the structural and atomic-molecular mobility of the particles that make up the solid. The mechanism of this phenomenon remains unresolved at present. The question of the nature of strength, the essence of the processes occurring in a material under load, remains unclear. In matters of strength, not only is there no complete physical theory, but even on the most basic ideas there are differences of opinion and opposing opinions.

ultimate goal The study of the mechanism of destruction should be the elucidation of the basic principles for the creation of new materials with desired properties, the improvement of existing materials and the rationalization of methods for their processing.

Strength is the property of solids that resists destruction, as well as irreversible changes in shape. The main indicator of strength is the tensile strength, determined at the break of a cylindrical sample, previously subjected to annealing. By strength, metals can be divided into the following groups:

fragile (temporary resistance does not exceed 50 MPa) - tin, lead, bismuth, as well as soft alkali metals;

strong (from 50 to 500 MPa) - magnesium, aluminum, copper, iron, titanium and other metals that form the basis of the most important structural alloys;

high-strength (more than 500 MPa) - molybdenum, tungsten, niobium, etc.

The concept of strength is not applicable to mercury, since it is a liquid.

The tensile strength of metals is indicated in table 1.

Table 1.

Metal strength

Majority specifications strength is determined as a result static test for stretching. The sample, fixed in the grips of the tensile testing machine, is deformed under a static, smoothly increasing load. During testing, as a rule, a tensile diagram is automatically recorded, expressing the relationship between load and deformation. Small deformations are determined with very high accuracy by strain gauges.

To eliminate the influence of the dimensions of the samples, tensile tests are carried out on standard samples with a certain ratio between the effective length l 0 and the cross-sectional area F 0 .

The most widely used samples are of circular cross section: long with l 0 /d 0 = 10 or short with l 0 /d 0 = 5 (where d 0 is the initial diameter of the sample).

On fig. 1a is a tensile diagram of mild annealed steel. Under a load corresponding to the initial part of the diagram, the material experiences only elastic deformation, which completely disappears after the load is removed.

Up to point a, this deformation is proportional to the load or applied stress

where P is the applied load; F o - the initial cross-sectional area of the sample.

The load at point a, which determines the end of the straight section of the tension diagram, corresponds to the limit of proportionality.

Theoretical limit of proportionality- maximum stress up to which a linear relationship between stress (load) and strain is maintained

σ pc \u003d R pc / F 0.

Since there may be errors in determining the position of point a on the diagram, they usually use conditional limit of proportionality, which is understood as a voltage that causes a certain amount of deviation from a linear relationship, for example, tg alpha changes by 50% of its original value.

The linear relationship between stress and strain can be expressed by Hooke's law:

σ = E epsilon,

where epsilon \u003d (delta l / l o) 100% - relative deformation;

delta l - absolute elongation, mm;

l 0 - the initial length of the sample, mm.

Fig.1 Tensile diagram of mild steel (a) and scheme for determining the conditional yield strength σ0.2 (b)

The coefficient of proportionality E (graphically equal to tg alpha), characterizing the elastic properties of the material, is called the modulus of normal elasticity.

At a given stress value, with an increase in the modulus, the value of elastic deformation decreases, i.e., the rigidity (stability) of the structure (product) increases. Therefore, the modulus E is also called the stiffness modulus.

The value of the modulus depends on the nature of the alloy and changes insignificantly with changes in its composition, structure, and heat treatment.

For example, for various carbon and alloy steels after any treatment, E = 21000 kgf / mm 2.

Theoretical elastic limit- the maximum stress up to which the sample receives only elastic deformation:

σ pack = Р pack / F 0 .

If the acting stress in the part (structure) is less than σ yn, then the material will work in the area of elastic deformations.

In view of the difficulty of determining σ yn, they practically use conditional elastic limit, which is understood as the stress that causes a permanent deformation of 0.005-0.05% of the initial estimated length of the sample. In the designation of the conditional elastic limit, the value of the residual deformation is indicated, for example, σ0.005, etc.

For most materials, the theoretical limits of elasticity and proportionality are close in magnitude. For some materials, such as copper, the elastic limit is greater than the proportional limit.

Yield strength- physical and conditional - characterizes the resistance of the material to small plastic deformations.

Physical yield strength- stress at which there is an increase in deformation under constant load

σ t \u003d P T / F 0.

In the tensile diagram, the yield strength corresponds to a horizontal section c - d, when plastic deformation (elongation) is observed - the "flow" of the metal at a constant load.

Most of the technical metals and alloys do not have a yield plateau. For them, most often conditional yield strength- stress causing permanent deformation equal to 0.2% of the initial design length of the sample (Fig. 1, b):

σ0.2 \u003d P 0.2 / F 0

With further loading, the plastic deformation increases more and more, being evenly distributed over the entire volume of the sample.

At point B, where the load reaches its maximum value, in the weakest point of the sample, the formation of a “neck” begins - a narrowing of the cross section; the deformation is concentrated in one area - from a uniform one it passes into a local one.

The stress in the material at this point in the test is called the tensile strength.

Tensile strength(tensile strength) - stress corresponding to the maximum load that the sample can withstand before failure:

σ in \u003d P in / F 0.

In its physical essence, σ in characterizes strength as resistance to significant uniform plastic deformation.

Beyond point B (see Fig. 1, a), the load decreases due to the development of the neck, and at point k, under load Pk, the sample is destroyed.

True resistance to destruction- the maximum stress that the material can withstand at the moment preceding the destruction of the sample

S K \u003d P to / F K,

where F K is the final cross-sectional area of the sample at the fracture site.

Despite the fact that the load P to<Р в, вследствие образования шейки F K

True voltages. The considered strength indicators: σ t, σ in, etc., with the exception of S k, are conditional stresses, since when determining them, the corresponding loads are attributed to the initial cross-sectional area of the sample F 0, although the latter gradually decreases as the sample is deformed. A more accurate idea of the stresses in the sample is given by true stress diagrams (Fig. 2). Fig.2 Diagram of true (S) and conditional (σ) stresses: ψ - transverse narrowing of the sample. The true stresses S i = P i /F i are determined from the load P i and the cross-sectional area F i at the moment of testing. Approximately to point b (Fig. 2,) i.e. point B in fig. 72, a, the difference between true and conditional stresses is small and S B \u003d σ c. Then the true stresses increase, reaching the maximum value S k at the moment preceding the destruction. In tensile testing, in addition to strength characteristics, plasticity characteristics are also determined. 2.

Physical foundations of plasticity of metals The development of the theory of the mechanical properties of solids, as is known, proceeded from the mechanics of an absolutely rigid body, in which deformations are not taken into account at all, through the theory of elasticity, which is the first approximation and is suitable in cases of small and reversible deformations, to the theory of small elastic plastic deformations. The theory of the interaction of atoms in a crystal lattice, developed over 40 years ago, was in sharp conflict with experimental data on the strength of crystals. Two ways out of this situation were proposed. Both of them are based on the fact that in a real crystal, as in solid materials in general, there are inhomogeneities and imperfections. It is precisely because of the imperfection of the structure that premature plasticity arises in real bodies. Further, the opinions of different researchers diverged. Some believed that a real crystal consists of pieces of an ideal crystal, between which there are weak points. Plastic flow occurs only at weak points. Others believed that weak points, if they play a role in plasticity, then only as sources of overvoltage. In other words, large local overstresses are necessary for plastic flow, as, for example, was shown in experiments on the control of the formation of plastic shear. Undoubtedly, the study of the structure of a real crystal and the various defects that may exist in it is an important task in its significance. However, it is debatable whether it is necessary to base the theory of plasticity on taking into account these phenomena, or whether it is possible to develop a theory of plastic deformation of an ideally regular crystal lattice with subsequent consideration of the role of various defects. A number of authors prefer to proceed from the assumption of the presence in the crystal lattice of regularly distributed defects with special properties. It is assumed that the plastic flow of crystals is the movement of these defects (dislocations) in the crystal lattice. The latest experimental data confirm the dislocation concepts to a certain extent. However, the fundamental question of the appearance of dislocations in the process of plastic deformation still remains insufficiently clarified. Therefore, it is necessary to pay special attention to the experimental verification of the theory of dislocations. It is possible that such a test and a corresponding refinement of the theory will contribute to the convergence of different points of view. A variety of materials subjected to the action of external mechanical forces, at the very initial stages of loading, change their size and shape reversibly. The deformations observed in this case are called elastic. The study of the elastic properties of solids is important because the elastic constants are a measure of interparticle forces in solids. The phenomena of shape change of solids under the influence of external forces are very complex. The final changes that occur in solids under the influence of external forces are determined by a combination of a number of processes, each of which in itself is still completely unclear due to the lack of satisfactory and complete ideas about the nature of bonding forces in solids, about their structure, about the nature thermal motion, etc., in other words, due to the lack of an exhaustive theory of the crystalline state. However, there is no doubt that the main and general phenomena occurring in solids under the action of external forces are atomic and molecular displacements. It is known that the phenomena that occur during the shape change of solids under the action of external forces depend to a large extent on the structure and are closely related to the processes of diffusion, relaxation, recrystallization, and phase transformations, and to a very large extent depend on temperature. Because of this, the problem of elastic and plastic form changes in solids - the problem of plasticity, in fact, is part of a more general problem - the problem of the mobility of atoms and molecules in solids, which includes: elasticity, imperfect elasticity, plasticity, creep, twinning, phase transformations , diffusion, relaxation, recrystallization and other (similar) phenomena. Thus, the development of the physical doctrine of plasticity requires the coverage of a wide range of phenomena, some of which were listed above, and is inseparable from the solution of the following fundamental problems: problems of the general theory of the solid state; problems of interparticle forces in solids; problems of ideal and real structure of solids; problems of thermal motion in solids. Plastic- the ability of a body (metal) to plastic deformation, i.e. the ability to obtain a residual change in shape and size without discontinuity. This property is used in the processing of metals by pressure. Plasticity characteristics are elongation and relative contraction. According to the degree of plasticity, metals are usually subdivided as follows: highly plastic- (relative elongation exceeds 40%) - metals that form the basis of most structural alloys (aluminum, copper, iron, titanium, lead) and "light" metals (sodium, potassium, rubidium, etc.); plastic- (relative elongation lies in the range between 3% and 40%) - magnesium, zinc, molybdenum, tungsten, bismuth, etc. (the most extensive group); fragile- (relative elongation less than 3%) - chromium, manganese, kolbat, antimony. High cleaning of brittle metals somewhat increases ductility. The alloys obtained on their basis are almost not amenable to pressure treatment. Industrial products from them are often obtained by casting. Relative extension. Relative elongation is a conditional characteristic of plasticity. This is explained by the fact that absolute elongation consists of two components: uniform elongation delta l p, proportional to the length of the sample, and local, concentrated elongation in the neck delta l w, proportional to the cross-sectional area of the sample. Hence it follows that the proportion of local deformation, and hence the values of delta lres and δ for short samples is greater than for long ones. At the same time, for different materials, the relative value of uniform and local deformations varies over a wide range. Most ductile materials deform with the formation of a neck. In this case, uniform deformation is 5-10% of local deformation, for alloys of the duralumin type 18-20%, for brass 35-45%, etc., but not more than 50%. For brittle materials or those in a brittle state, the neck is not formed and practically delta l rest = delta l p . The relative elongation of metals characterizes table 2. Table 2. plasticity of metals. Relative contraction. In plastic materials, the relative narrowing more accurately characterizes their maximum plasticity - the ability to local deformation and often serves as a technological characteristic in sheet stamping, etc. 3.

Theoretical and technical strength The technical (real) strength of metals is 10-1000 times less than their theoretical strength, determined by the forces of interatomic cohesion. For example, for iron, the theoretically calculated value of the tear resistance S OT = 2100 kgf/mm 2 . Technical strength of iron: S FROM \u003d 70 kgf / mm 2, σ in \u003d 30 kgf / mm 2. Such a large difference is explained by the fact that the theoretical strength corresponds to an ideal defect-free crystal lattice of the metal. In real metals, there are always dislocations and other defects in the crystal lattice, inclusions, microcracks, etc., which reduce strength and initiate destruction (Fig. 3). Fig. 3 Dependence of strength on the number of dislocations and other defects of the crystal lattice (scheme by I. A. Oding): 1 - pure, annealed metals; 2 - alloys hardened by alloying, heat treatment, plastic deformation (hardening), etc. Pure, annealed metals have minimum strength at a dislocation density of about 10 7 -10 8 cm -2 . With a decrease in the number of dislocations, the resistance to deformation, i.e., the strength of the metal, increases and can reach the theoretical value. Convincing evidence of the validity of this position was obtained in the study of metal whiskers - whiskers with a thickness of 0.5-2 μm and a length of up to 10 mm with a practically defect-free (dislocation-free) crystal structure. Whiskers of iron with a thickness of 1 μm have a tensile strength σ in \u003d 1350 kgf / mm 2, i.e., almost theoretical strength. Due to their small size, mustaches are used to a limited extent. An increase in the size of the whiskers leads to the appearance of dislocations and a sharp decrease in strength. To the right of point 1 (see Fig. 3), with an increase in the number of dislocations (defects), the strength of metals increases. This is used in hardening methods such as alloying, heat treatment, cold plastic deformation, etc. The main reasons for hardening are an increase in the number (density) of dislocations, distortion of the crystal lattice, the occurrence of stresses, refinement of metal grains, etc., i.e., everything that hinders the free movement of dislocations. The limiting dislocation density for hardening is approximately 10 12 cm -2 . At a higher density, submicroscopic cracks form in the metal, causing destruction. Conclusion The issues of plasticity and strength of solids are of paramount importance for many branches of technology. The plasticity and strength of this material ultimately determine the possibility of using it in building structures, in machine parts, in instrument designs, in tools for mechanical processing of solids, and in many other cases. The same properties also determine the possibility of mechanical processing of a given material by pressure (forging, rolling, stamping, cutting) and set the power of the machines used for this purpose. At present, the problem of strength and plasticity of solids should be considered from the standpoint of two areas of interest - physical and technical. The first of them includes: a) elucidation of the physical nature of the plasticity and strength of solids based on the study of elementary processes occurring during deformation and destruction, b) the systematic accumulation and generalization of new facts and patterns of behavior of solids under conditions encountered in practice. The second area of interest includes all problems related to the use of solids in engineering with a general phenomenological description of their force and deformation behavior under different types of stress state and under various operating conditions, using this information to calculate the strength and plasticity of machine parts and structures based on formal theories of strength and plasticity. Studies of the nature of the strength and plasticity of solids are necessary to create a rigorous physical theory of their plastic deformation and fracture. The construction of such a theory consists primarily in solving the problem of the deviation of the structure of solids from the ideally correct one under the influence of mechanical factors and the influence of violations of the ideal structure of solids on their plasticity and strength. It is quite obvious that the absence of a physical theory based on a variety of experimental facts that have been accumulated as a result of many years of work on the problem will continue to hinder the solution of a number of possible practical issues. The most important of them are as follows: in the development of principles for the creation of new materials with desired properties, in the improvement of existing materials, in determining ways to further rationalize their processing. The enormous national economic significance of these tasks is obvious. Meanwhile, there is still a noticeable gap between the demands of technology in relation to the strength and plasticity of materials for various conditions of their operation in machines and structures and the possibilities of theory for finding ways to solve the problems at hand. Now, at best, we have at our disposal only sketches of a possible theory of individual phenomena, as well as some experimental foundations of the theory, covering far from completely the questions that confront us. Bibliography 1. Alexandrov, A. V. Fundamentals of the theory of elasticity and plasticity: a textbook for universities. - M.: Higher school, 1990. - 399 p. - ISBN 5-06-000053-2. 2. V. E. Gul, Structure and strength of polymers, 2nd ed., M., 1971. 3. Zubchaninov, V. G. Fundamentals of the theory of elasticity and plasticity: a textbook for students of engineering specialties of universities / V. G. Zubchaninov. - M.: Higher school, 1990. - 368 p.: ill. - ISBN 5-06-000706-5. 4. V. L. Indenbom and A. N. Orlov, The problem of fracture in the physics of strength, "Problems of Strength", 1990, No. 12, p. 3; 5. G.V. Kurdyumov. Physical foundations of strength and plasticity of solids. – M.: - 1975. 6. Mechanical properties of materials, trans. from English, ed. G. I. Barenblatt. Moscow, 1966. 7. Fundamentals of the theory of elasticity and plasticity: a textbook for students of engineering specialties of universities / V. G. Zubchaninov. - M. : Higher school, 1990. - 368 p. : ill. - ISBN 5-06-000706-5. 8. V. R. Regel, A. I. Slutsker, and E. E. Tomashevsky, Kinetic Nature of Solids Strength, Moscow, 1974. 9. V. V. Sokolovsky, Theory of Plasticity, 3rd ed., Moscow, 1969. 10. Feodosiev V.I. Strength of materials. - M.: Publishing house of MSTU im. N.E. Bauman, 1999. P. 86. ISBN 5-7038-1340-9. 11. Numerical methods in the theory of elasticity and plasticity: textbook. allowance for un-comrade. / B.E. Pobedrya. - M.: MGU, 1981. - 343 p. Plasticity of the mixture characterize its mobility, i.e., the ability to spread under the influence of its own weight or external forces applied to it. The mobility of almost all mortar mixtures is determined by the immersion depth (in cm) of a standard cone with a mass of (300:4:2) g. Cone 3, held by the ring, is brought to the mixture so that its apex touches its surface. Then the cone is released and it sinks into the mixture under its own weight. Mortar mobility depends primarily on the amount of water and binder, the type of binder and aggregate, the ratio between binder and aggregate. Fatty mortars are more mobile than lean ones. Ceteris paribus, solutions on lime and clay are more mobile than on cement; solutions on natural sand are more mobile than solutions on artificial sand (crushed). The mobility of the mortar mixture can be adjusted by increasing or decreasing the consumption of binder or water. By increasing the content of water and binder in the mortar mixture, more plastic (mobile) and workable mixtures are obtained. A workable mortar mixture is obtained with a correctly assigned grain composition of its solid components (sand, binder, additives). The binder dough not only fills the voids between the grains of sand, but also evenly envelops the grains of sand with a thin layer, reducing internal friction. The quality of masonry and plaster depends on the workability of the mixture. Delamination- the ability of the mortar mixture to separate into solid and liquid fractions during transportation and pumping it through pipes and hoses. You can check the mixture for stratification in a simplified way as follows. A mortar mixture is placed in a bucket with a layer about 30 cm high and its mobility is determined by a reference cone. After 30 minutes, the upper part of the solution (about 20 cm) is removed and the depth of immersion of the cone is determined for the second time. If the difference in cone immersion values is close to zero, then the mortar mixture is considered non-separable, if it is within 2 cm, the mixture is considered to be of medium segregation. If the composition of the mortar mixture is chosen correctly and the water-binding ratio is set correctly, then the mortar mixture will be mobile, workable, it will have good water-retaining capacity and will not delaminate. Essay by discipline: "Technology of structural materials" "Physical foundations of plasticity and strength of metals" Is done by a student Checked by teacher Introduction The main mechanical properties are strength, plasticity, elasticity, viscosity, hardness. Knowing the mechanical properties, the designer, when designing, reasonably selects the appropriate material that ensures the reliability and durability of machines and structures with their minimum mass. Plasticity and strength are among the most important properties of solids. Both of these properties, mutually related to each other, determine the ability of solids to resist irreversible shaping and macroscopic destruction, i.e., the separation of the body into parts as a result of microscopic cracks arising in it under the influence of external or internal force fields. For the technologist, plasticity is very important, which determines the possibility of manufacturing products by various pressure treatment methods based on the plastic deformation of the metal. Materials with increased plasticity are less sensitive to stress concentrators and other embrittlement factors. In terms of strength, ductility, etc., a comparative assessment of various metals and alloys is made, as well as their quality control in the manufacture of products. In physics and technology, plasticity is the ability of a material to receive residual deformations without destruction and to maintain them after the load is removed. The property of plasticity is of decisive importance for such technological operations as stamping, drawing, drawing, bending, etc. The strength of solids, in a broad sense, is the property of solids to resist destruction (separation into parts), as well as irreversible change in shape (plastic deformation) under the influence of external loads. In a narrow sense - resistance to destruction. The purpose of this work is to study the physical foundations of plasticity and strength of metals. 1.

Physical foundations of the strength of metals Strength is a fundamental property of solid bodies. It determines the ability of a body to resist without destruction the action of external forces. Ultimately, as is known, strength is determined by the magnitude and nature of the interatomic bond, the structural and atomic-molecular mobility of the particles that make up the solid. The mechanism of this phenomenon remains unresolved at present. The question of the nature of strength, the essence of the processes occurring in a material under load, remains unclear. In matters of strength, not only is there no complete physical theory, but even on the most basic ideas there are differences of opinion and opposing opinions. The ultimate goal of studying the fracture mechanism should be to elucidate the basic principles for creating new materials with desired properties, improving existing materials, and rationalizing methods for their processing. Strength is the property of solids that resists destruction, as well as irreversible changes in shape. The main indicator of strength is the tensile strength, determined at the break of a cylindrical sample, previously subjected to annealing. By strength, metals can be divided into the following groups: fragile (temporary resistance does not exceed 50 MPa) - tin, lead, bismuth, as well as soft alkali metals; strong (from 50 to 500 MPa) - magnesium, aluminum, copper, iron, titanium and other metals that form the basis of the most important structural alloys; high-strength (more than 500 MPa) - molybdenum, tungsten, niobium, etc. The concept of strength is not applicable to mercury, since it is a liquid. The tensile strength of metals is indicated in table 1. Table 1. Metal strength Most strength specifications are determined by static tensile testing. The sample, fixed in the grips of the tensile testing machine, is deformed under a static, smoothly increasing load. During testing, as a rule, a tensile diagram is automatically recorded, expressing the relationship between load and deformation. Small deformations are determined with very high accuracy by strain gauges. To eliminate the influence of the dimensions of the samples, tensile tests are carried out on standard samples with a certain ratio between the effective length l 0 and the cross-sectional area F 0 . The most widely used samples are of circular cross section: long with l 0 /d 0 = 10 or short with l 0 /d 0 = 5 (where d 0 is the initial diameter of the sample). On fig. 1a is a tensile diagram of mild annealed steel. Under a load corresponding to the initial part of the diagram, the material experiences only elastic deformation, which completely disappears after the load is removed. Up to point a, this deformation is proportional to the load or applied stress where P is the applied load; F o - the initial cross-sectional area of the sample. The load at point a, which determines the end of the straight section of the tension diagram, corresponds to the limit of proportionality. Theoretical limit of proportionality- maximum stress up to which a linear relationship between stress (load) and strain is maintained σ pc \u003d R pc / F 0. Since there may be errors in determining the position of point a on the diagram, they usually use conditional limit of proportionality, which is understood as a voltage that causes a certain amount of deviation from a linear relationship, for example, tg alpha changes by 50% of its original value. The linear relationship between stress and strain can be expressed by Hooke's law: σ = E epsilon, where epsilon \u003d (delta l / l o) 100% - relative deformation; delta l - absolute elongation, mm; l 0 - the initial length of the sample, mm. Fig.1 Tensile diagram of mild steel (a) and scheme for determining the conditional yield strength σ0.2 (b) The coefficient of proportionality E (graphically equal to tg alpha), characterizing the elastic properties of the material, is called the modulus of normal elasticity. At a given stress value, with an increase in the modulus, the value of elastic deformation decreases, i.e., the rigidity (stability) of the structure (product) increases. Therefore, the modulus E is also called the stiffness modulus. The value of the modulus depends on the nature of the alloy and changes insignificantly with changes in its composition, structure, and heat treatment. For example, for various carbon and alloy steels after any treatment, E = 21000 kgf / mm 2. Theoretical elastic limit- the maximum stress up to which the sample receives only elastic deformation: σ pack = Р pack / F 0 . If the acting stress in the part (structure) is less than σ yn, then the material will work in the area of elastic deformations. In view of the difficulty of determining σ yn, they practically use conditional elastic limit, which is understood as the stress that causes a permanent deformation of 0.005-0.05% of the initial estimated length of the sample. In the designation of the conditional elastic limit, the value of the residual deformation is indicated, for example, σ0.005, etc. For most materials, the theoretical limits of elasticity and proportionality are close in magnitude. For some materials, such as copper, the elastic limit is greater than the proportional limit. Yield strength- physical and conditional - characterizes the resistance of the material to small plastic deformations. Physical yield strength- stress at which there is an increase in deformation under constant load σ t \u003d P T / F 0. In the tensile diagram, the yield strength corresponds to a horizontal section c - d, when plastic deformation (elongation) is observed - the "flow" of the metal at a constant load. Most of the technical metals and alloys do not have a yield plateau. For them, most often conditional yield strength- stress causing permanent deformation equal to 0.2% of the initial design length of the sample (Fig. 1, b): σ0.2 \u003d P 0.2 / F 0 With further loading, the plastic deformation increases more and more, being evenly distributed over the entire volume of the sample. At point B, where the load reaches its maximum value, in the weakest point of the sample, the formation of a “neck” begins - a narrowing of the cross section; the deformation is concentrated in one area - from a uniform one it passes into a local one. The stress in the material at this point in the test is called the tensile strength.

The relative elongation, determined on long samples, is denoted δ 10, on short ones δ 5, and always δ 5 > δ 10.

Naturally, the properties of a freshly prepared mortar mixture and a hardened mortar are completely different. The main properties of the mortar mixture are workability, plasticity (mobility) and water-holding capacity, and hardened solutions - density, strength and durability.

The correct choice of the scope of solutions depends entirely on their properties. Properties of mortar mixtures

Workability- the property of the mortar mixture to easily fit in a dense and thin layer on a porous base and not delaminate during storage, transportation and pumping.

It depends on the plasticity (mobility) and water-holding capacity of the mixture.

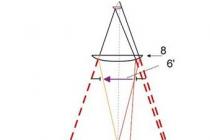

Cone height 180 mm, base diameter 150 mm, apex angle 30°.

In the laboratory, the cone is mounted on a tripod (Fig. 1, a), in the conditions of the construction site it is hung on a chain with a ring (Fig. 1.6).

Fig.1. Tripod

The divisions on a scale of 6 or on the surface of the cone determine the depth of its immersion in the mixture. If the cone is immersed to a depth of 6 cm, this means that the mobility of the mortar mixture is 6 cm.

The type of binder is selected and the composition of the solution is set depending on the required strength of the solution and the operating conditions of the building.

Mortar mix with normal water-retaining capacity - easy to process and work to be laid, soft, does not reach for the plasterer's shovel, provides high labor productivity.

Properly selected and well-mixed mortar mixture densely fills irregularities, depressions, cracks in the base, therefore, a large contact area between the mortar and the base is obtained, as a result, the solidity of the masonry and plaster increases, and their durability increases.

The mortar mix is often transported by dump trucks and moved through pipelines using mortar pumps. In this case, it is not uncommon for the mixture to separate into water (liquid phase) and sand and binder (solid phase), as a result of which plugs can form in pipes and hoses, the elimination of which is associated with large losses of labor and time.

The stratification of the mortar mixture is determined in the laboratory.

The difference in cone immersion values of more than 2 cm indicates that the mortar mixture is stratified.

Plasticizing additives, both inorganic and organic, increase the water-holding capacity of mortar mixtures and reduce their stratification