Food metal detector price Vemata is available to a wide range of customers. Our range includes easy-to-use equipment that detects foreign particles with high accuracy. The model refers to conveyor-type devices used to work with food.

Characteristics

All incoming signals are digitally processed by the unit. This completely eliminates malfunctions. A high level of noise immunity allows the device to be effectively used as part of a production line. Coming from neighboring equipment electromagnetic waves or vibration will not affect its operation.

The detector has an "open alarm" option. It is also convenient when the unit is operating as part of a single line. If particles are detected, actions can be quickly coordinated with the rest of the working modules. Such a solution ensures that there is no downtime leading to a decrease in productivity.

Display options in the model are different. When foreign elements are detected, an audible or light alarm is triggered. It is also possible to stop the conveyor belt.

Additional equipment also affects the price of a food metal detector. Together with this unit, a checkweigher of a similar (conveyor) type is often used. Such a device is necessary for dynamic weight control. The mass is checked at any of the given speeds. Guaranteed high accuracy result.

For convenience, the metal detector has a memory for 99 positions. A record is kept of the total number of nonconformities found.

The basic package includes diversion devices for defective products. A box for collecting marriage is provided.

Technological nodes conveyor metal detector made of stainless steel. Joints and connections are sealed, so that the tested substance does not get inside the machine.

Modern industrial devices are characterized by a simple design. The conveyor metal detector also matches this. If necessary, it can be easily disassembled for sanitation or inspection. In addition to the favorable price of a food metal detector, all this is also the advantages of the proposed model.

Supply and repair of equipment - quickly and at competitive prices

Engineering company Vemata offers a wide range of industrial units for packaging and sorting products. You can purchase equipment for various production tasks from us.

The price of a food metal detector, a traysealer, a marker and other machines is affordable. All equipment sold has a warranty. If you need service or repair of detectors and filling machines, please contact our technical center. Learn more about the service by phone.

Peculiarities

- - memory for 99 products.

- - self-learning function.

- - record of statistical data (number of identified nonconformities).

- - function of self-diagnostics (with a possibility of shutdown according to the set parameters).

- - open alarm, allows you to coordinate the detectors with other equipment.

- - various forms of alarm indication - stop, sound, signal lamp.

- - a device for removing the defective product to the side.

- - a box for collecting defective products.

The conveyor metal detector MD-3-2UM is an analogue of the MD-3-M, but only two-level, in order to achieve even greater sensitivity, it is designed to detect various inclusions of black / non-ferrous metals.

At the conveyor metal detector MD-3-2UM high level sensitivity and therefore will ensure the detection of metal inclusions at any point in the opening, which makes it an effective control device. Can be easily integrated into existing production lines. The detector will detect metal inclusions at any line speed. The Detector comes with a remote control panel, which is installed in close proximity to the detector. The control panel comes with a sound / light alarm, as well as a sensor unlock button. When the sensor is triggered, the operator must go to the detector and check for the presence of metal, press the detector unlock button. Only then is it possible to start the conveyor belt.

Peculiarity metal detector MD-3-2UM is that it can work both with adhesive tape and with tape, for the connection of which metal parts are used (staples / bolt / rivets, etc.). In this case, the metal detector is not turned on for the period of the connection. This period is about 1 meter of the conveyor belt, regardless of the speed of the belt.

MD-3-2UM metal detectors have reliable dust/moisture protection. To ensure trouble-free operation and reduce false alarms, the detector must be protected from shock/vibration, and also removed as far as possible from sources of electrical radiation.

Characteristics

Cash payment

You can pay in cash with the courier upon delivery of products in Moscow and the Moscow region.

Bank transfer (for legal entities)After placing an order, send an email [email protected] site order number and your details of the organization.

Bank account payment (for individuals)You can pay for the order in any commercial bank.

After placing an order, send an email [email protected] website order number and full name with contact details, we will issue you an invoice for payment.

When paying for and receiving products from a warehouse or by courier, inform us in advance about the desire to pay by credit card.

Pickup from the warehouse

Pickup from the warehouse is possible during its opening hours:

Mon-Fri: from 10:00 to 18:00

Pickup free.

Delivery of small-sized cargo in Moscow within the Moscow Ring Road:

Up to 30 thousand rubles - from 500 rubles;

From 30 t. rub. - for free.

Delivery of small-sized cargo in Moscow in the Moscow region - individually.

Delivery of bulky cargo in Moscow and the Moscow region - individually.

We will certainly coordinate a convenient delivery time with you.

Delivery to the regions of the Russian FederationCarried out by transport companies. We cooperate with all major transport companies.

Choice transport company depends on your wishes and negotiated with each client individually.

The cost of cargo delivery to the terminal of the transport company is free.

At your request, we will send the order through the Federal State Unitary Enterprise Russian Post.

The guarantee for all products presented in our online store is provided in accordance with the Consumer Protection Law. The purchase of all goods is carried out only from official suppliers of products from the central warehouses in Moscow. We do not sell "beautiful fakes", we only have original goods, no "confiscation" and counterfeit goods, which are now much more on the market than "real", branded goods. If the buyer wishes, we can present a certificate for any product - be it a hair band or a professional hair dryer.

The device is manufactured only according to those. task of the Customer, a sample of those. assignments are sent upon request.

Conveyor metal detectors "MIKON"

Conveyor metal detectors "MIKON"designed to detect foreign metal objects in the flow of raw materials (material, product) located on the conveyor in order to prevent damage technological equipment engaged in its processing (grinding, crushing, cutting, packaging, etc.). The abbreviation T / N denotes the standard size of the metal detector, set by the user, depending on the width of the conveyor belt - (T) and the maximum height of the flow of raw materials (material, product) located on the conveyor - (H), the dimension is meters.

The detection of a metal object is accompanied by:

- highlighting on the display the number of the section of the control zone in which the object was found;

- issuing a command for the actuator in the form of a short-term (0.5 - 1.0 s) closing of the dry contacts of the relay.

The resolution of the device in displaying the transverse coordinate of the detected object is provided by four (or eight) independent sections of the control zone evenly distributed along the length of each panel.

Conveyor metal detector brand MD

LLC "Promsnabkomplekt" specializes in the supply of domestic equipment for security and search operations, conveyor metal detectors, metal detectors. The "MD800" set includes a base unit and two electronic metal sensors: DM1 and DM2. One of the sensors (DM2) can be used as an additional one if it is necessary to increase the size of the controlled area. The power supply of the sensors and the transmission of signals about the detection of metal objects by them is carried out by means of three-core cables connected to independent ports of the base unit. The formation of signals to actuators is carried out using a relay with potentially independent contact groups.

Advantages: The modular principle of construction of the MD800, which ensures full electromagnetic compatibility of the operating sensors, allows, due to their respective mutual placement, to form the required configuration of the controlled area.

Technical characteristics of metal detectors MD400 MD600 MD800:

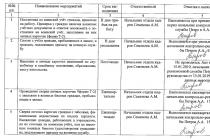

| Metal detector brand | MD 400 | MD 600 | MD 800 |

|

Sensitivity - detected metal objects at a distance of 150 mm from the center of the sensor |

Ball d=7-8 mm | Ball d=6-7 mm | Ball 100 gr. |

|

Controlled flow speed |

0.3-3 m/s | from 0.3-3 m/s | 0.3-3 m/s |

|

Width of metal object detection zone |

400 mm | 600 mm | 800 mm |

|

Permissible load current at the relay output of the base unit At AC 220 V or DC 28 V |

5 A | 5 A | 5 A |

|

Power consumption from mains 220 V |

no more than 10 W | no more than 10 W | no more than 10 W |

|

Permissible distance of the sensor from the base unit, |

up to 100 m | up to 100 m | up to 100 m |

|

Sensor dimensions |

600/200/40mm | 600/200/40mm | 800/200/40mm |

|

Sensor weight |

3 kg | 3.5 kg | 4 kg |

|

Base unit dimensions |

130/75/160 mm | 130/75/160 mm | 130/75/160 mm |

|

Base unit weight |

no more than 1 kg | no more than 1 kg | no more than 1 kg |

|

Operating temperature range |

minus 40…+65 °С | - 40…+ 65 °С | - 40…+ 65 °С |

|

Degree of protection against dust and moisture:

|

IP67 IP30 at least 15 years |

IP67 IP30 at least 15 years |

IP67 IP30 at least 15 years |

Metal detector hidden opening, MD Web

Metal detector hidden opening Webdesigned to address security issues, prevent theft of non-ferrous and ferromagnetic metals. The metal detector is installed hidden, while providing a culture of inspection. The small size of the metal detector structure (the absence of a traditional “frame”) allows it to be built in (camouflaged) into existing architectural structures (passages, corridors, doorways) and office furniture. High reliability of detection, low level of false alarms, is ensured by high noise immunity, absence of mechanical influences and multicomponent analysis of carried metal objects (weight, volume, type of metal).

Opportunities of the selective metal detector:

- the possibility of hidden installation of a metal detector;

- the presence of two independent channels for detecting non-ferrous and ferromagnetic metals;

- high selectivity, uniformity of the field in the working area is not lower than 80%;

- high noise immunity;

- simplicity of design, installation, configuration and maintenance;

- compactness of the metal detector (weight no more than 12 kg);

- competitive cost of the device.

Technical characteristics of the selective metal detector:

Mounting a selective metal detector:

The metal detector is made for hidden installation - the product consists of two emitting, two receiving sensors and a control and indication unit. Receiving sensors are placed at the top, emitting sensors are placed at the bottom, relative to the conditional control zone. Moreover, various options for placing sensors are possible, under the floor or ceiling, on the wall or built into the wall. Detection zone - height 1.8-2.0 m, width 0.9-2.0 m.

- remote location of the control and information unit from the control zone;

- warranty and service.

Reception management team, halls for negotiations and conferences, entrances and corridors of office buildings, banks, entertainment complexes, general education and sports schools.

Metal detector monopanel, MD Web

Metal detector monopanel (column), MD Webmade of solid wood (on request from any material). For mobile use of the metal detector, an autonomous battery supply and a prefabricated monopanel structure consisting of three 0.6 m segments are provided, which allows the metal detector to be transported by passenger cars and quickly install the metal detector in the required monitoring place. The control and indication unit is carried out at a distance of up to 30 meters or placed directly in the monopanel. The metal detector is controlled from the remote control, which excludes unauthorized changes in the settings of the metal detector.

Features of the metal detector monopanel:

- hidden installation of the metal detector eliminates the possibility of studying the operation of the metal detector by criminal elements in order to block the metal detector;

- hidden installation of the metal detector does not block the passage;

- ease of installation;

- a monopanel can be made of any material or camouflaged in the interior (mirror, decorative panel);

- the absence of a traditional "frame" eliminates the mechanical impact (shocks, bumps) on the metal detector;

- high throughput combined with reliable detection;

- the control and indication unit is placed on the panel or taken out;

- output of information and control to a PC;

- connection of external additional devices (video camera, etc.);

- the weight of the metal detector assembly is 25 kg.

Technical characteristics of the metal detector monopanel:

Monopanel (column) dimensions: height - 2.0 m; width - 0.3 m; thickness - 0.1 m. Hidden installation of a metal detector is possible. The metal detector provides for the operation of turnstiles directly in the control zone of the metal detector.

- a monopanel (column) is attached to the wall, or located in space, the control zone is 0.9 m;

- hidden installation of a metal detector is possible;

- the possibility of individual design, (color, material, shape), various mounting solutions (camouflage);

- synchronous operation of the metal detector is provided.

The metal detector is recommended for installation:

Offices, banks, halls for receiving officials and delegations, cultural and entertainment institutions, administrative buildings, schools, lyceums, hospitals, theaters, cinemas, sports complexes.

Designed for the security of VIPs, where the installation of a traditional frame is not appropriate.

The camouflaged installation of the metal detector allows for a hidden inspection mode for visitors.

Features of the 2-meter metal detector:

- inspection culture (detection of objects prohibited from being carried against the background of household metal items for personal use);

- remote location of the control and indication unit from the control zone;

- output of information and control to a PC;

- connection of external additional devices (video camera, etc.);

- the possibility of individual design, (color, material, shape), various mounting solutions (camouflage).

Technical characteristics of the 2-meter metal detector:

- The metal detector is made in the form of two panels. The panel is made of solid wood (on request from any other material).

- The control of the metal detector is carried out from the remote control, which excludes unauthorized changes in the settings of the metal detector.

- Panel dimensions: height - 2.0 m; width - 0.3 m; thickness - 0.1 m.

- Control zone: height 2.0 m; width - 2.0 m.

- It is possible to install a metal detector hidden.

Competition forces manufacturers to find the optimal balance between profit and selling price of products and constantly care about quality. For this, modern specialized equipment is used, including conveyor metal detectors.

What is a conveyor metal detector?

The conveyor metal detector is designed to detect foreign inclusions from ferrous or non-ferrous metals and alloys in controlled products. This is a stationary device on stable wheels. It automatically scans objects on a moving conveyor belt. When metal objects or particles are detected, the metal detector triggers sound and light indication and stops the conveyor. Further actions depend on the configuration: either the metal detector will wait manual restart after removal of the rejected product by the operator, or the metal detector rejects the contaminated product on one's own, moving it to a special container without interrupting work.

With a certain degree of confidence, it can be argued that foreign objects in the process production can be found in any product. And it's not about the flaws. technological processes. There can be two reasons: periodically occurring equipment breakdowns and the human factor. As a result, fragments or parts can get into the manufactured products. production equipment(nuts, bolts, springs, etc.), as well as foreign objects brought in by employees (paper clips, buttons, hairpins, coins, buttons, etc.).

Such metal products can be found both in raw materials and in the final product. They pose the greatest danger when they get into food. That's why food industry is the main potential consumer of conveyor metal detectors.

Why do you need a conveyor metal detector?

There are several reasons:

- Quality control of incoming raw materials. increase the responsiveness of the enterprise. They allow timely rejection of inappropriate raw materials and termination of cooperation with unscrupulous suppliers.

- Quality control of the final product. Not only the image of the enterprise depends on this, but also the health of consumers.

- Protection of metal detector related equipment. Detection of metal objects or inclusions in the early stages of the technological cycle makes it possible to avoid equipment breakdowns and financial costs for its repair. This applies to mixers, dough mixers, dough sheeters - equipment that can be damaged by foreign metal objects.

- Correspondence international standards quality - HACCP, ISO 22000:2005. These documents require a radical change in approaches to product quality control. At the same time, the interests of the consumer are put at the forefront. Having a certificate of conformity HACCP or ISO 22000:2005 improves the company's image and increases the degree of consumer confidence.

What is HACCP and ISO 22000:2005

07/01/2013 in Russia came into force Technical regulation Customs Union TR TS 021/2011 "On safety food products". This document requires food manufacturers to develop, implement and maintain procedures based on HACCP principles.

HACCP, from the English Hazard Analysis and Critical Control Point, in translation means "Hazard Analysis and Critical Control Points". This system is a set of developed documents, organizational structure, resources and production processes. Its implementation means that the enterprise fully complies with the requirements of TR CU 021/2011. The presence of a certificate allows you to apply the HACCP mark of conformity to the packaging, which informs buyers about the safety of products.

ISO 22000:2005 "Food and food safety management systems" also contains HACCP requirements, but is a more extended document. It is more focused on enterprises that supply their products to European markets.

The principle of operation of the conveyor metal detector

The operation of the conveyor metal detector is as follows. Three spools of wire are placed parallel to each other in the body of the detector head. The coil located in the middle generates a high-frequency electromagnetic field, being an oscillator. In coils placed along the edges of the head housing, under the influence of an alternating magnetic field, an electric current arises. As long as the field remains uniform, the potential difference of the coil system is zero.

When products with metal inclusions pass through the metal detector, the electromagnetic field of one of the outermost coils changes. As a result, the total potential difference of the system becomes different from zero. The metal detector registers this fact with the operation of sound and light indication and stops the conveyor or independently moves products with metal inclusions into a separate container using a device called a "rejector".

What affects the sensitivity of a conveyor metal detector?

The sensitivity of a conveyor metal detector is affected by several factors:

- Composition of products. The more they contain moisture or salt, which increase electrical conductivity, the more difficult it is to detect a metal object.

- Product form. It is easiest to control products that are spherical or close to them in shape, and elongated products are the most difficult.

- The location of a product or metal object on a conveyor belt. The most sensitive zones of the metal detector are located along the edges of the frame, that is, in the immediate vicinity of the detector coils. The least sensitive areas are in the center of the frame.

- Foreign inclusion metal type. The metal that can be magnetized has the maximum effect on the electromagnetic field. It's easier to find.

- Working conditions. The sensitivity of the device is affected by magnetic or electric fields generated by other equipment, power supply parameters, detector vibration, sudden temperature changes environment, massive metal objects located nearby, etc.

Configuration options for conveyor metal detectors

There are various configuration options for conveyor metal detectors. Variable parameters in devices are:

1. The size of the product passage.

The size of the product passage is always smaller than the size of the frame opening of the conveyor metal detector

2. The sensitivity of the metal detector.

3. Electronic or touch control panel.

4. Rejection system:

- inclined plate;

- air jet;

- rotary pusher;

- pneumatic pusher on one or two sides;

- pneumatic lowering or extension of the table.

5. The presence of a container for rejection.

6. Adjustment of conveyor speed.

7. Conveyor belt made of food-grade PVC (as standard) or polyurethane (more durable and environmentally friendly).

Such equipment can be manufactured according to individual technical specifications and have parameters different from the factory ones.

Conclusion

Conveyor metal detectors are auxiliary equipment, but they take product quality control to another level. Given that it is advisable to organize the production of food products in accordance with the requirements of TR CU 021/2011. Availability metal detectors necessary for those manufacturers who want to protect consumers from products contaminated with metal objects, appreciate the image of their trademark. Also, the presence of a metal detector in the workplace is often mandatory requirement retail chains purchasing products.

The conveyor metal detector is designed to detect metal objects in the packaged product. IN manufacturing process it is difficult to exclude the ingress of foreign objects into the manufactured products. Most often, these metal particles enter products from production lines. Such production “troubles” will be eliminated by a metal detector.

The metal detector is able to detect non-magnetic metals (non-ferrous metals, stainless steel). When metal is detected in the product, a sound and light signal is triggered, the pusher (optional) automatically dumps defective products into the collection container.

The conveyor metal detector is used both in line and separately.

The main advantages of a conveyor metal detector:

1. Digital intelligent metal detector.

2. Allows you to recognize all kinds of metals, such as iron, copper, gold, silver, stainless steel, etc.

3. High sensitivity and stability.

4. Dust and moisture resistance

5. Automatic setting with reversible and direct rotation: loading and output of the product is carried out without manual intervention.

The metal detector can be manufactured according to the individual technical specifications of the client, which guarantees maximum satisfaction of the customer's requirements.

| Model |

IMD-I-4018 |

| Detection Width |

400 mm |

| Detection height |

180 mm |

| Conveyor belt width |

360 mm |

| Conveyor belt length |

1200 mm |

| Conveyor belt speed | 25 m/min (fixed, regulation-option) |

| Detector sensitivity, Fe |

≥ 0.7mm |

| Detector sensitivity, SUS304 |

≥1.5mm |

| Control |

Touch screen |

| Memory |

for 50 products |

| Product weight |

5-10 kg |

| Execution |

Completely made of 304 stainless steel |

| Actions when metal is detected |

Horn, conveyor stop |