The perfect test sheet. This example shows what a flawless print should look like.

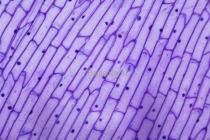

recurring black dots arranged vertically on a white test sheet. This test sheet characterizes the most common type of marriage - a spot breakdown of the photoconductor photolayer. Breakdowns come in different diameters: from barely visible dots to greasy spots. In this case, it becomes necessary to completely replace the photoconductor, since there is no technology for its restoration. This decision is made depending on the client's requirements for print quality, since small dot breakdowns when printing only text are almost indistinguishable and there is no need to replace the photoconductor. But over time, the dots increase in size. Then it will be possible to think about replacing such an important component.

Defective magnetic shaft. A vertical stripe on a black test sheet indicates a scratch on the magnetic roller, which is a defect. In this case, the magnetic roller must be replaced, since the light strip significantly degrades the quality of printing text and pictures.

A solid vertical black line on a white test sheet. The appearance of a continuous or intermittent vertical single black or several stripes along the edges of the white test sheet indicates serious damage to the photo layer on the drum. Otherwise, such drums are called "burnt". These defects are clearly visible to the naked eye. The photo layer at the site of damage has a characteristic brown color or, if absent, exposes the following layers. The photoconductor must be replaced. On a black test sheet with such defects, a discontinuous band is visible along the edge.

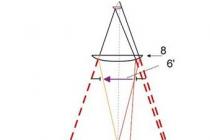

An example of the marriage of Samsung and Xerox cartridges. They differ from defects on HP and Canon cartridges due to the difference in the technological device. Spots on both test sheets, vertical streaks on the black test sheet, and repeated horizontal dots on white indicate the need to replace the large rubber roller, photoconductor.

The toner is low. The photo shows what the test sheet looks like when the toner cartridge runs out. This is especially noticeable on the black test sheet. This example is not a defect. It's just time to refill the cartridge.

Divorces and waves on a light dough. The appearance of streaks and waves on a light test indicates improper storage of the cartridge, as a result of which it has become damp. In this case, the consumable must be cleaned of old toner and refilled in a new way.

Vertical stripe, pallor print. The paleness of the print, a well-defined vertical stripe on the black test result from scratches on the magnetic roller, as well as its strong wear. The same symptoms appear when the photoconductor is burnt out. To improve print quality, it is advisable to replace worn or damaged components.

Toner stuck on the squeegee. Sometimes toner can stick to various parts of the cartridge due to the temperature rise in the printer during operation, significantly reducing print quality. It is necessary to clean the squeegee, remove excess toner from the parts.

We talked about the main defects of cartridges and their impact on print quality.

Each user, after purchasing new equipment, seeks to test it in action as soon as possible. Of course, this also applies to printers. The only sure way to test a printer is to print a solid page. This procedure will make sure that all the basic device settings have been set correctly, in addition, you can make sure that the color is transmitted in full accordance with the desired result.

In addition to the information listed, printing a test page on an HP printer will let you know the exact version of the drivers and the model of the device you are using. All the information provided may well be useful in case there are any problems or additional questions.

Test print on an HP printer

Press the left mouse button on the “Start” button in the taskbar and from the list of services select “Control Panel.

Move the mouse cursor over the selected printer and press the right button. The printer context menu will appear. From the context menu, select the "properties" command and click on it with the left mouse button.

In the Properties menu, open the General tab and left-click on the Test Print command. If the printer is being used for the first time or has not been used for a long time, you may need to wait a few seconds (15 to 30) before printing starts. It's just that the printer driver needs time to collect all the information about the system. In the future, the print processing speed will be faster. The test page parameters of any printer are defined by default and absolutely all printer parameters are tested during printing. The test page on different models may differ.

When printing is finished, evaluate the test page. It should contain graphics, text, samples of absolutely all colors. There should be no distortion or unevenness. If the print was made with an inkjet printer, then there should be no ink streaks.

When the printer finishes printing the page, you will be prompted to save the print settings. If all the test page settings suit you, you can simply click on the command “save print settings by default.

How to print an HP test page without a computer?

To begin, load plain white paper of the appropriate size into the input tray.

A test print page for inkjet printers is printed as follows: turn off the device with the button, press the Sheet button without releasing it, press the ON button, release it, continue to hold the Sheet for about 10 seconds.

What problems can arise?

But sometimes the following problem occurs: the test page did not print correctly. In this regard, the question arises of what to do in this case and how to still print this page? So, if the test page does not print correctly, then one possible problem is old or “broken” drivers.

To solve it, you need to download and install their updated version. But what if this action did not help and the problem associated with the fact that the printer does not print is still relevant? In this case, give full rights to "Everyone for" C:\Windows\System32\spool\PRINTERS, then delete the desired printing device in the registry branch "HKEY_USERS\.DEFAULT\Printers.

In addition, give the normal user the rights that the administrator has and install a new driver under his name. After that, you can withdraw the previously granted rights from him. You should also disable UAC. If the steps taken do not help, then you should run the Process Explorer utility and, during printing, pay attention to what rights are missing.

From a printer for home use, unless, of course, it is used to reproduce photographs, it is rarely required anything other than the clarity of letters and a long service life. But if the machine is used to print color products, the requirements for it immediately increase. And here it becomes important not only the number of dots per inch or image clarity, but also color.

Printer printing is checked using special test pages.

When is the check carried out

The quality of printouts is important for any document - both monochrome and color. Accordingly, the testing procedure is carried out in several cases.

- When buying a new device, it is often not possible to check the operation of the device in the store. However, at home, nothing prevents the user from downloading the relevant tests and finding out how much the playback quality corresponds to the true one.

- Cartridges are exhausted over time and you need to either charge the device by purchasing the appropriate set, or buy a new cartridge. However, not all inks are compatible, and sometimes it takes a long time to look for special ones for HP equipment. However, it is not only a matter of the mismatch between the characteristics of the liquid for different printing devices - it is also a matter of different colors.

When you purchase a cartridge or refill kit from a licensed retailer, there is a much greater chance that the ink color will match the machine exactly. However, not all users have the physical or financial ability to purchase special ink. Accordingly, the user has to select all compatible options.

Of course, after installing a new cartridge, it is necessary to conduct a test to find out to what extent the shades match the previous ones.

- They also check a color printer during a planned transfer of the device to other inks - from pigment to water, for example. In this case, you should make sure that the device works adequately.

Test pictures will also be required to determine the condition of the print head. Over time, it gets dirty and printing the corresponding image allows you to both determine the level of contamination and clean the nozzles. This procedure is standard and included in the printer software.

Analysis of the device

To find out how high-quality ink is purchased, the purchased printer of the Epson line is tested. They will need high-quality paper - white matte, since any shade of the sheet will ruin the test, the actual printing device and the cartridge with new ink.

The test is colorful pictures with certain specified parameters, which allow you to evaluate the gradient, hue matching, playback capabilities and other printing parameters. The test tasks themselves are easy to find on the Internet and download to the memory of an HP device.

Printer test pictures should include:

- gradient transition from black to white, with the inclusion of a given number of shades of gray;

- a portrait, or rather a photograph, with natural skin color and unmasked pores;

- the image of light details on a dark background, as well as dark elements on a light one;

- test strips with different colors.

In addition, the printheads use a test black page to clean the nozzles or analyze the condition. If its shade is not saturated and not uniform, a cleaning procedure should be carried out. In the same Epson, for this, “Check nozzles” are selected in the window and cleaning is assigned based on the test result.

Each such element serves to check one of the playback parameters. If the device will be used only for home printing, you can limit yourself to the first two parameters.

But if you intend to print photos for commercial use, you should pay attention to all factors. At the same time, when analyzing the resulting image, one should pay attention not to the exact reproduction of color in comparison with the original, but to the balance of the selected ink set.

The color picture for checking the printer is analyzed as follows:

- first of all evaluate the fill in gray. If all its shades exactly match the reference image, the ink can be used. If the color is distorted in at least one position, alas, the cartridge is far from ideal. It is the very presence of an extraneous shade that allows you to identify unsuitable inks. This is relevant for analyzing the operation of any HP devices - Epson, Canon;

- drawing the smallest details, both light and dark, also indicates the quality of the ink. With high-quality materials, the drawing will be as detailed as possible;

- color distortion - best determined by a human portrait or an image of living objects. The color scheme of inanimate objects - a still life is not so informative, while it is much easier to determine the realism of the shade of human skin.

To some extent, you can correct the color reproduction using the settings of the device itself. If the Epson printer test fails, you can try using the software settings. To do this, in the appropriate tab, select "Printer Settings" and adjust the halftone curve.

Introduction When drawing up a methodology for testing printers, the main question that arose was whether it should be made separate for different types of devices. Under the general name of printers, in fact, devices that are quite different in capabilities and purpose are hidden. An attempt to find and apply a universal cure for all diseases does not always lead to success - the patient may die. Nevertheless, the desire to adhere to some common standards and a unified approach to testing peripheral devices in this category eventually prevailed, however, with certain reservations. First of all, these were restrictions on the types of printers that fall under the scope of this technique. We deliberately extended its action only to color inkjet and laser printers, without adapting it to dot matrix and thermal sublimation printers, due to the specificity and low prevalence of such models on the Russian market. In principle, this document can be used as a guide in the future when testing monochrome laser printers, excluding from it the items that regulate the definition of color rendering quality.

The methodology we have created concerns mainly the two most important characteristics of printers, which, of course, are print quality and productivity. Of course, there is a third indicator - the cost of the product, which excites all users, but it is not within the competence of this technique and is dictated by the seller of the goods. We can only subjectively evaluate the conformity of the price of the printer with its other characteristics we are considering. In addition, of course, there are other factors that influence the decision to purchase a particular printer.

Before proceeding directly to the testing methodology, let's say a few words about other aspects that we will take into account when considering the next model of the printing device. These are the following parameters:

Specifications;

Print technology;

Structural execution;

Software;

Printer kit.

It makes no sense to describe in detail the above points - most users who deal with printers in the slightest degree understand what is at stake.

Print quality

The indicator "quality of the press" has the generalized character. In fact, it is formed as a result of the interaction of several components, which together make it possible to end up with a pleasing picture on a paper sheet. The total result will depend on the printing technology, ink, paper, software and some other factors. Naturally, in our case, the task is to control what we get at the output.One of the main factors that form a high-quality image is the ability of the printer to provide correct color reproduction. Let's make a reservation right away that we are talking about the technical side of this issue, and not about the most beautiful and pleasant-looking image. As a result of its work, the printer must print the image that matches the electronic original as closely as possible in three color components (RGB) in each pixel. Here it would be appropriate to recall that, of course, a finished color copy in practice is always worse than the original, since it is almost impossible for the printer to accurately reproduce the entire range of original colors. In addition, an important element in the operation of any printer is the ability to provide high-quality halftone transmission. Problematic for this task in some cases is the inability of the printer to provide a uniform color fill in the entire brightness range. Usually areas of very light tone become the most problematic. In color printing, black is formed by mixing RGB colors, and the end result is not always satisfactory due to their imbalance. Another aspect of obtaining a high-quality image on paper is the resolution of the printer, which allows for the correct transmission of the smallest details. Many modern printers have a very high print density declared by manufacturers, which in practice does not always have a direct relationship with the real physical resolution, and the true state of affairs can only be found out during testing.

After we have considered the problems that arise when trying to achieve maximum print quality, it's time to choose ways to specifically implement the task before us.

The resulting prints are evaluated subjectively and objectively. The first method is based on the traditional visual method, which allows you to identify flaws visible to the naked eye. The second method is based on a more accurate and unbiased assessment of print quality. It consists in the fact that the printed test images are scanned on a reference scanner and converted into digital form. Further, with the help of special software, RGB indicators are taken from special "plates", and the degree of deviation in color characteristics from the original image is determined. In order to take into account the degree of error in the results introduced by the scanner itself, it is calibrated before testing using a proprietary Kodak Q-60 color target.

The above methods for evaluating print quality are fully applicable to test images of color printing. If only black ink is used for printing, the procedure for testing prints is somewhat simplified due to the fact that there is no need to study color characteristics.

Print speed

Print speed is indicated in the documentation for their printers by all manufacturers. The data given in the specifications refer to various modes of operation and are expressed in the number of pages printed per minute. However, not all so simple. In theory, if manufacturers have a unified approach to determining speed for all models, the numbers should be quite correct, but as you can imagine, there is no certainty that all companies use the same reference documents when determining print speed. . In order to compare printers from different companies in terms of print speed, it is still better to conduct your own testing. In this case, we use the same templates to determine the performance of all models, regardless of their belonging to a particular company, and we can make a reasonable comparison between them in this indicator.To determine the print speed, we will use three pre-prepared electronic layouts printed on A4 sheets. The first of the templates is one page of text. The second layout consists of a combination of text and color graphics. In the first two cases, standard office paper (80 g/m^2) is used for printing. As the third layout, a color test image prepared by us is used, printed on the best quality photo paper recommended by the manufacturer. The print mode in this case is selected with the highest possible density. The print time in all cases is fixed from the moment the Print command is issued until the sheet exits the tray.

Basic Tests

The list of basic tests includes those that later allow you to compare the quality and speed of printing of any printer models when they perform the most typical functions. For ease of comparison of final results, A3 and A4 printers use the same paper size. List of basic tests:- Test for the quality (speed) of color printing (A4 office and photo paper). The TF1 file is used (description of the files used below).

- Monochrome print quality test (A4 office paper). A TF3 file is being used.

- Monochrome print speed test (text, A4 office paper). The file is TF4.

- Mixed print speed test (b/w text/color graphics, A4 office paper). The file is TF5.

- Monochrome print resolution test (A4 office paper). The file is TF2.

- Color print resolution test (A4 photo paper). The file is TF2.

- Test for moisture resistance of ink on paper after the print has dried (moist cotton wool).

Additional tests

In addition to the above basic tests for quality and print speed, based on the study of the ability of printers to perform their main functions, it is possible to conduct additional tests based on the specific capabilities of specific models. We are talking about the fact that some printers allow you to print on CDs, roll paper, media of increased thickness, etc. and so on. Additional tests allow you to evaluate the quality of such functions. The advisability of conducting additional tests will be decided based on the results of studying the characteristics of the printers that were tested.Test procedure notes

Now about how the testing itself is carried out. Before it starts, the printer heads are calibrated. If certain printer models require the installation of an additional cartridge to obtain a photorealistic image, then a similar step is taken. The print mode is made with the "default" settings, in the absence of any comments in the text. The final test parameters are selected depending on the specific characteristics of the devices under consideration.Test template files

TF1 fileIn order to determine the ability of printers to produce high-quality color printing, a special target was created. It contains several color and one black-and-white artistic image, serving for a subjective assessment of quality.

In addition, the target has a rectangle with a black gradient fill from 0 to 100 percent, as well as a seven-color plate with "steps" of varying intensity and known RGB values. With their help, you can objectively assess the degree of correctness of the color reproduction of printers.

TF2 file

This test file in PDF format is designed to determine the resolution of printers. The USAF 1951 test image can be used to determine printer resolution. On this target there are several groups, each consisting of six elements. The elements in each group are progressively reduced and numbered from one to six. Each element in the group is represented by two triplets of rectangles arranged vertically and horizontally. Each new group of elements is smaller in size than the previous one. The group nesting level is quite large and allows you to find out the maximum print resolution that the printer is capable of.

TF3 file

A doc-format file designed to determine the quality of monochrome text printing consists of several dozen lines of font of various sizes and styles, which also allows you to determine, to some extent, the maximum resolution.

TF4 file

This template is designed to determine the speed of monochrome text printing. A doc-format file contains one page of text in 10 point Times New Roman font, regular font, single line spacing.

TF5 file

In order to determine the printing speed of mixed documents (monochrome text/color graphics), a file in doc format is used. It contains text in 10 point Times New Roman font, regular font, single line spacing, and two color images (diagrams).

Evaluation of the quality of color reproduction based on objective indicators

When evaluating the color rendering quality of a printer, we will to some extent adhere to the principles of the methodological approach described in the article. about testing scanners.The image of the target printed on the printer (TF1 file) digitized after scanning in color mode with the optical resolution of the scanner is used to determine the RGB color components at certain points using special programs, such as Adobe PhotoShop. To do this, the results are taken on all eleven "sites" of different brightness of seven color "rulers": Red, Green, Blue, Black, Yellow, Magenta, Cyan.

Further, all the data obtained for each control point from the scanned image are entered into a special table.

Based on the results for all seven colors, the integral coefficient of correctness of the reproduction of original colors by the printer is determined. It is calculated as the sum of the modulo difference between the color component (RGB) values of each of the control points in the scanned image and the reference file, then divided by seventy-seven.

The lowest value obtained as a result of calculations will be a sign of the most accurate reproduction of the color palette of the original by the printer among those who took part in the test. Note that the index we propose is suitable only for a comparative analysis of the quality of color rendering between models and cannot be an absolute assessment.

Color balance and midtone quality

Based on the measured RGB values of the black gradient rectangle, a graph is plotted that reflects the quality of the printer's performance of this procedure. The x-axis represents the distance expressed in pixels, and the y-axis represents the RGB values of the pixels.The final picture in the case close to ideal looks approximately the same as can be seen on the graph. The lines from all three black RGB components merge into a single whole, and the absence of dips and peaks indicates their balance. The desired range of color component values (RGB) should be between 0 and 255.

We will consider our methodology as a basic document available for changes and development as it is applied in practice.

In practice, he proved that he is able to print large volumes of photographs efficiently and economically. “The introduction of a model with built-in tanks is definitely an event that will influence the world of inkjet printing,” notes a representative of the magazine's test lab. "Photo Workshop", - The appearance of the model is a long-awaited decision and a huge step towards the consumer. The Epson L800 photo printer will become an indispensable assistant for photographers working in small and home studios.

Comparison of Epson T50/T59/P50 and L800 printers

After the Epson L800 printer with built-in CISS entered the market, many of our users began to ask the question of which printer is better and what should they buy?

To answer this question, you need to understand the needs:

- WHAT will you need to print - high-quality photographs on high-quality media or simple color brochures on plain paper?

- How many prints per day do you need to print?

- available budget.

If you still opted for T50-based photo printers, namely T50, T59, P50, L800 and do not know which one suits you better, we suggest that you familiarize yourself with the comparative table of technical characteristics of these printers:

Characteristic | Models T50/T59/P50 | Model L800 |

Number of colors / cartridges | 6 | 6 |

| Ink | Epson Claria aquatic | Epson aquatic |

Maximum resolution, dpi | 5760x1440 | 5760x1440 |

Minimum drop size, pl | 1,5 | 1,5 |

| Guarantee | 1 year | 6 months or 3000 prints (depending on which comes first) |

Weight, kg | 5,4 | 6,2 |

| Printer price | T50 - $130 P50 - $155 | $320 |

| Epson ink price: | Epson Claria ink 1 cartridge (11 ml) - $14 1 ml - $1.23 1 l - $1230 | Epson ink 1 bottle (70 ml) - $18 1 ml - $0.26 1 liter - $260 |

| Compatible ink price: | InkTec 1 l - 600 rubles DCTec 1 l - 900 rubles | InkTec 1 l - 600 rubles DCTec 1 l - 900 rubles |

CISS | CISS Resetters- 1450 rubles | built in |

| Reset ink levels | Need autochips | Free service program resetters |

| Stopping the Printer to Replace Ink | Approximately every 20 photos A4 | Approximately through 200 photos A4 |

OS support | MacOS, Windows | Windows |

You can already purchase ink for this printer from us!

InkTec E0010 ink (Dye - a new series of inks for 6 Epson R270, 1410, T50, P50, L800 color printers)

| |

Attention, the utility for resetting chips is distributed by us for free!

The SuperPrint development team (Resetters) has released a new program RESETTERS for servicing Epson inkjet printers, which replaced the SPUA program, which performed only one function - resetting the waste counter (diaper).

Compatibility: Windows XP (x32), (x64), Windows 7.

Russian language

The program can perform the following functions:

Checking the Current Waste Ink Counter

- reset the waste ink counter (some models require a RESET CODE)

- cleaning the print head

- enhanced cleaning of the print head during initial refueling

- read and write printer serial number

- read and write USB ID

- read and write HEAD ID

- creating an EEPROM backup dump

- paper feed test

- nozzle check and test

- printout of color fills

- initialize (disable) PF deterioration offset

- getting the status of the printer

- read ink level

The use of the program is free. All functions are supported incl. and diaper reset function. For some models, this function works after entering the code that will be applied to each CISS Resetters-Superprint. You can also buy codes in our online store - Get a code to reset a diaper

Section added to the program Knowledge base. Here we collect the most popular questions about inkjet printing and provide links to the most detailed articles with answers to these questions. You do not need to spend a lot of time on the Internet, shoveling through a lot of information to find the answer to your question. All answers will be in Knowledge base.

If you have topics of questions that you think should be added to the Knowledge Base, please write about it in the section