Thanks to the fan installed on the roof of the spray booth, a vacuum is created that provides intensive air suction from the interior of the cabin. Filter elements capture solid paint pigments, suspensions, aerosols and hold them securely on the inner surface of the filter.

The cabin of the spray booth is designed on the basis of the best technical solutions of the leading European manufacturers of spray equipment.

The cabin is equipped with high-quality spark-safe fans made in Italy, inertial cleaning filters-separators made in France.

Explosion-proof lamps made in the Czech Republic provide optimal glare-free illumination of work stations. Application in the construction of a double filtration system made of modern materials allows you to achieve a degree of air purification up to 97%.

Uniform distribution of the air flow in the working area makes it possible to obtain coatings of higher quality. The painting booth has a progressive modular design, made of galvanized steel.

STANDARD EQUIPMENT

- Galvanized Steel Camera Housing Kit

- Suction system

- Electrical control cabinet

- Explosion-proof luminescent lamp, (Czech Republic)

- Fan explosion-proof

- Fastener kit (handles, bolts, nuts, etc.)

- Non-woven filter kit

- Set of filters-separators, made in France

- Technical documentation set

- Packing in a box

Height of a working zone - 2330 mm.

Case height with fan - 3200 mm.

ADDITIONAL OPTIONS

- Supply plenum

- Additional lamps

- Fans with increased performance

- Frequency regulation of fan rotation

- Filter clogging control device

SPECIFICATIONS

|

Working area depth up to 0.37 m |

|||||

|

Working area length, mm |

|||||

|

Case length, mm |

|||||

|

Hull depth, mm |

|||||

|

Working area depth, mm |

|||||

|

Case height, mm |

|||||

|

Fan productivity, m3/hour |

|||||

|

Fan power, kW |

| Working area depth 0.87 m | |||||

| Working area depth 1.37 m | |||||

| Working area depth 1.87 m | |||||

| Working area depth 2.37 m |

* Development of non-standard solutions at the request of the customer.

Spray booths are robust units designed for intensive work.

Cameras are developed on the basis of the best technical solutions of leading European manufacturers

painting equipment. In the production of spray booths, high-quality

accessories. Uniform distribution of air flow in the working area makes it possible

obtain high quality coatings.

The equipment is designed for a long service life, allows you to work with a wide range of

paints and varnishes, providing optimal working conditions at minimal cost.

Compact spray booth with dry filter OKS 0110.10

The filter elements are high-tech inertial filter-separators capable of

withstand up to 15 kg of filtered material per 1 m 2 of working surface and non-woven filters

materials. Application in the construction of a double filtration system made of modern materials

allows you to achieve a degree of air purification up to 97%.

Designed for manual application of paint coatings by air, combined and airless spraying with simultaneous removal of solid residual suspensions from the working area and air purification from harmful impurities.

The chamber is used for installation in the finishing shops of furniture enterprises, in production processes in which flammable, explosive and technical solvents are used, as well as in the production of window and door blocks, chairs, cribs and other woodworking industries. Satisfies fire safety and sanitary standards.

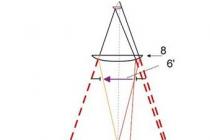

Principle of operation

Spray booths are robust units designed for intensive work. The filter elements are high-tech inertial separator filters capable of withstanding up to 15 kg of filtered material per 1 m 2 of the working surface and fine filters. The chambers are developed on the basis of the best technical solutions of the leading European manufacturers of painting equipment. Painting booths are equipped with high-quality fans in intrinsically safe design made in Italy, inertial cleaning filters-separators made in France. Explosion-proof lamps made in the Czech Republic provide optimal glare-free illumination of work stations. The use of a double filtration system made of modern materials in the design makes it possible to achieve a degree of air purification up to 97%. Uniform distribution of the air flow in the working area makes it possible to obtain coatings of higher quality. Spray booths have a progressive modular design, made of galvanized steel.

Filtration scheme

Standard equipment

- Suction system

- side walls

- Electrical control cabinet

- Fluorescent lamp (in explosion-proof design), made in the Czech Republic

- Fan (intrinsically safe), made in Italy

- Non-woven filter kit

Options (change of equipment)

- Supply plenum

- Additional lamps

- Fans with increased performance

- Development of non-standard solutions at the request of the customer

The equipment is designed for a long service life, allows you to work with a wide range of paints and varnishes, providing optimal working conditions at minimal cost.

Price: from 129,000 depending on the model

Manufacturer

Request

Description:

Compact spray booths OKS 0110.10 and OKV 0112.10

Spray booths are robust units designed for intensive work. The cameras are developed on the basis of the best technical solutions of the leading European manufacturers of painting equipment. In the production of spray booths, high-quality components are used. The uniform distribution of the air flow in the working area makes it possible to obtain high quality coatings.

The equipment is designed for a long service life, allows you to work with a wide range of paints and varnishes, providing optimal working conditions at minimal cost.

Small spray booths with water curtainOKV 0112.10

The filter elements are a cascade of water curtains, a sprinkling system and filters made of non-woven materials. The use of 4 stages of filtration in the design makes it possible to achieve a degree of air purification up to 99%.

TOequipment OKV 0112.10:

- A set of parts for the camera body made of galvanized steel 1.2 and 1.5 mm thick (steel manufacturer NLMK).

- Water curtain system

- Sprinkler system

- Stainless steel drain type circulation pump

- polyurethane sealant.

- Package

Compact spray booth with dry filter OKS 0110.10

The filter elements are high-tech inertial filter-separators capable of withstanding up to 15 kg of filtered material per 1 m 2 of working surface and filters made of non-woven materials. The use of a double filtration system made of modern materials in the design makes it possible to achieve a degree of air purification up to 97%.

TOequipmentOKS 0110.10:

- A set of parts for the camera body made of galvanized steel with a thickness of 1.2 and 1.5 mm (steel manufacturer NMLK).

- Fastener kit (handles, bolts, nuts, etc.)

- Non-woven filter kit

- Set of filters-separators, pr-in France

- Package

Additional equipment for OKS 0110.10 and OKV 0112.10:

- Fan medium pressure VTS14-46 explosion-proof, fan motor explosion-proof.

(APPROVAL No. PPC 00-34341 federal service on environmental, technological and nuclear control for the use of fans at fire and explosion hazardous facilities)

- Fluorescent lampexplosion-proof IP66 (Czech Republic)

(PERMISSION No. PPC 00-32335 of the Federal Service for Ecological, Technological and Nuclear Control for the use of lamps at fire and explosion hazardous facilities)

- Electrical control cabinet IP66 with a three-phase power control relay, for automatic emergency shutdown of all electrical equipment when the mains voltage deviates from the norm. The cabinet is supplied with a set of cables, corrugated pipes, fasteners, pressure seals.

- Frequency regulation of fan speed.

- Filter clogging control device.

Specifications:

Options:

- Frequency regulation

- Explosion protection package

- Rotary table

- Filter clogging control device

- Development of non-standard solutions at the request of the customer