In our country, cheese production is considered a fairly popular business.

Like many other dairy products that are present in the diet of people, this product, it must be assumed, will always be in great demand.

A cheese factory is a profitable enterprise. Someone starts to open production from scratch, while someone already has some kind of food business.

Where to start a business?

Regardless of whether or not you have experience in this area, you should start with a business plan. It will provide an opportunity to assess the costs of opening a cheese factory, the difficulties associated with it, make a forecast for production and sales volumes, analyze demand, and decide what the assortment will be.

It should be remembered that in order to open a food production facility, you will need a large number of documents allowing you to engage in this business. You will also need to issue various certificates.

When you begin to draw up a cheese production business plan, you should decide on the pricing policy and the product sales market. To do this, you need to assess the demand of buyers in all parts of the market. At first, you will be able to sell products in your region, and as production volumes increase, increase sales at the expense of neighboring districts and regions.

Nutritional value of the dairy product

Cheese production is a fairly profitable business. For its organization, a large start-up capital is needed.

Cheese is a high-calorie protein product with great nutritional value due to the content of all the substances required by the human body in an easily digestible form. This includes proteins, peptides, fats, calcium and phosphorus salts, and amino acids.

Cheese varieties

According to technological features, natural cheeses are divided into rennet and fermented milk products. Rennet cheese is made by curdling milk with rennet. A fermented milk product is made by fermenting raw materials with special starter cultures.

Cheeses are also divided into classes:

Solid (rennet, having a solid consistency);

semi-solid (rennet, having a dense consistency);

soft (rennet or sour milk, having a soft texture);

brine (ripens in brine, contains a mass fraction of table salt).

Each such class can be subdivided into subgroups.

Production technology

Hard cheeses are made from curd mass, separated from whey, washed and pressed. Such cottage cheese in the right amount is placed under the press and is there for a long time until the taste appears. On average, it takes a month. The longer the aging, the better the palatability and the sharper the taste. The density of the finished cheese depends on the weight of the load.

The highest quality product is obtained from whole milk. Almost the same technology as hard cheeses is used to produce soft cheeses. But such a product is aged much less in time. The duration of this process is a maximum of a week, or it is not performed at all. Such cheese is not stored for a long time and is eaten in the near future.

The production technology of hard and soft cheese has other differences. The first types are more popular than the second.

Cheese making equipment

In order to establish at least a mini-production of cheese and conduct a high-quality production process, it is imperative to purchase specialized equipment.

You will need:

- long-term pasteurization bath with a volume of 100 liters;

Paraffiner with a volume of 75 liters;

Bath IPKS, having a volume of 200 liters;

Definitely a cheese press;

Two forms;

Two refrigeration units;

Desktop.

Product quality

The quality of the finished product depends on how good the ingredients used to make cheese are. Therefore, the following conditions must be observed:

buy milk only from healthy cows;

on the pH meter, the level of active acidity should be at least 6.8;

the composition should not contain antibiotics;

basic fat content within 3.5;

the presence in the composition of proteins is not less than 3.0%;

temperature at acceptance is not more than 12 °C.

It is required to conclude contracts with milk suppliers and prescribe in them the above requirements for the quality of raw materials, their quantity, payment terms, delivery method, as well as payment deferral, if necessary.

Production of a dairy product. Stage one

As an example, consider the manufacture of a solid type of product. Cheese production technology is a very complex biochemical process, which is carried out under the influence of microorganisms and enzymes. It requires adherence to a clear algorithm during the manufacture of the product.

The production of hard cheese includes the following steps:

milk preparation;

curtailment of raw materials, obtaining a homogeneous mass;

maturation;

salt cheese.

So, the first stage is the preparation of milk. What is it? The milk used should contain the required amount of protein. It depends on the yield of the product and the consumption of raw materials. First of all, the milk is cleaned and cooled to prevent the development of such microflora, which will lead to spoilage of raw materials. Milk purifying filters or separators will be needed here.

It is required to cool the milk to a temperature of 7 degrees on a plate cooler with the required capacity.

Second phase. Obtaining a homogeneous mass

The next step in the production of cheese is the maturation of milk. It is held from 12 to 24 hours. During this time, milk is gaining acidity.

Both raw purified milk and pasteurized milk require aging. A starter from lactic acid bacteria, and possibly rennet, is introduced into the pasteurized product. Next, the milk must be cooled to clotting temperature.

It is normalized on cream separators, pasteurized - on pasteurization-cooling units at a temperature of 74-76 degrees. The process takes approximately 20 seconds. During heat treatment, all vegetative forms of microorganisms are destroyed, enzymes are inactivated, and milk is prepared for clotting (up to 32 degrees). Before this, the acidity of the raw material must be at least 20 degrees Turner.

Third stage. cheese maturation

For rennet coagulation, the product is prepared in a cheese-making bath, sourdough from bacteria, a solution of calcium chloride are added. If necessary, rennet is also added. For hard cheese, sourdough from aromatic and lactic streptococci (1.0%) is mainly used.

In the production process, mature milk is often used - 1/5 of the total mass - to increase the Ca content and improve the quality of the clot. Rennet gives a guarantee of the formation of a strong clot in a short time.

Coagulation of milk is carried out at a temperature of 32 degrees for an hour. The resulting clot is cut and dried for 45 minutes, 1/3 of the whey is removed. To speed up dehydration, the cheese grain is reheated for 30 minutes, while the temperature must be maintained (40 degrees).

Then the cheese mass is dried for 50 minutes. The duration of treatment, therefore, is approximately 2-3 hours. The grain size should be 5-6 mm.

Final stage. Ambassador

Salting is the next step in cheese production. This process is carried out at the end of the curd drying stage. Before this, 70% of the serum is removed. Salty concentrated brine is introduced into the grain for 30 minutes with constant stirring. Next, move on to shaping.

The cheese grain is sent to the whey separator by the pump. From there it is poured into molds.

Within an hour, self-pressing occurs, and a single turning is necessary. Then the cheese mass is sent under the press for 4 hours, where its active acidity is greatly increased.

Then the cheese is dried for 10 days. At the end of this time, the heads are covered with a paraffin-polymer alloy.

It is required to carry out technochemical control of cheese production in order to determine how the process meets the standards. Now you know how to make cheese. But there are still nuances associated with the organization of production.

Preparation of documentation for the enterprise for the production of cheese

Before you open your cheese production shop, start production activities and purchase equipment, you need to obtain the necessary permits and complete the required documentation.

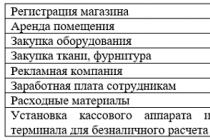

The cost estimate should include:

Obtaining rights to purchase or lease land and building permits.

Registration of your business.

Conclusion of the necessary contracts.

Obtaining licenses and certificates for products.

You need to take care of this in advance, otherwise you may experience various force majeure circumstances during the manufacture of products.

If you choose the legal form, it is better to give preference to a limited liability company or individual entrepreneurship. These options will help to significantly reduce the tax.

Cheese certification

Due to the fact that cheese is a product of the dairy industry, its certification is mandatory. For example, a declaration of conformity OKP 92 2511 is issued for Russian cheese. It is issued either for a contract or for a manufacturer with an exact indication of the batch size.

To obtain, you need the following papers: application, contract, constituent documentation of the applicant, label layouts, phytosanitary registration certificate, veterinary certificate.

Required documents and requirements of SES

When opening your own cheese production, as well as choosing any other type of economic activity, you certainly need to have a permit from the state sanitary and epidemiological service (SES), because the requirements of the legislation on sanitary and epidemic supervision are applicable to almost all types of activities.

There are a large number of regulations governing the scope of SES permits. That is why it is quite difficult to fulfill the requirements of this service at the enterprise, go through the procedure of examination and issuance of a permit, and, moreover, clearly learn about one's rights and obligations without the legal support of specialists.

List of documents

To successfully start and run a business, an enterprise must obtain:

1. Approval of a land management project for the allocation of a land plot.

2. Conclusion on the choice (allocation) of a land plot for construction.

3. Conclusion on the construction project.

4. Coordination on the commissioning of objects of reconstruction or buildings or permission to operate (for food manufacturers).

5. Conclusion on the compliance of the object with the provisions of the sanitary legislation.

6. Conclusion of the SES expertise on regulatory documentation for imported products, as well as domestic production, for the facility itself.

7. Coordination of the range of food products produced by the enterprise and (or) sold.

Documents that are required to obtain a permit in the SES

1. Certificate of state registration of the enterprise (copy).

2. Certificate of the taxpayer (copy).

3. Agreement with the owner on the lease of premises or territory.

4. Technological map of production, a list of equipment used at the facility, as well as the capacity of the facility.

5. Number of employees, data on medical examinations.

6. Plan of the rented premises, which indicates the installed equipment.

7. The project for the reconstruction of the premises (with a change in the functions of the premises) and the conclusion of the SES on the approval of this project.

8. Passport for the ventilation system.

9. Contract for garbage collection.

10. Agreement with Profdisinfection.

11. Help statistics with printing.

And finally

It may be necessary to provide other documents that regulate the activities of the enterprise or are mandatory for obtaining a permit.

Knowing the manufacturing technology of this product and having a sufficient understanding of the necessary equipment, as well as the documentation required to start your business, you will be ready to open your own personal mini-cheese factory.

The food market in our country is very diverse and is represented by a wide range of various products. Despite the apparent saturation, novice businessmen may well create good competition for existing food producers. Cheese products are one of such goods, the production of which can be a profitable investment of money. Cheese production today is one of the most profitable areas in the food industry.

Brief business analysis:

Business setup costs:700,000 - 1,000,000 rubles

Relevant for cities with a population: no limits

Situation in the industry:high competition

The complexity of organizing a business: 3/5

Payback: 10 – 12 months

Advantages and disadvantages of this business

Cheese production has the following advantages:

- this product is in demand in our country - according to the statistics of cheese consumption per capita, we are in the top thirty of the world ranking;

- after the import substitution program, the amount of cheese on the shelves of retail outlets has significantly decreased due to the cessation of the import of the product from abroad, in connection with which the resulting niche can play into the hands of novice businessmen;

- raw materials for cheese production are not expensive and are widely available in our country.

Naturally, as with opening any business, the following risks may arise during the production of cheese:

- oversaturation of the sales market in some regions of the country. Before starting production, it is necessary to carefully study the market for similar products in order to assess the possibility of competing with existing manufacturers;

- rather short shelf life of finished products, as well as the need to control the temperature regime in warehouses;

- possible risk of producing low-quality products due to insufficiently high rates of raw materials used in production.

Business Options

When opening a cheese production workshop, you can set up a mini-production at home or a large-scale workshop that produces a large assortment of finished products in large volumes.

The choice and determination of production capacity may depend on such factors:

- the value of the starting capital of a businessman;

- the desire of the entrepreneur himself to associate himself with high risks, but, at the same time, to provide himself with large profits;

- experience in this field or a team of qualified specialists;

- the existence of a raw material base close to the location of the workshop;

- the need for your cheeses in the market for finished products.

Required documents for starting a business

To open and legally carry out a business in the field of cheese production, the following documents will be required:

- certificate of state registration as an individual entrepreneur or legal entity;

- certificate of registration as a taxpayer;

- when renting a finished premises - a lease agreement with all documents confirming the rights of the owner;

- during the construction of the workshop - approval of the construction project, a documented conclusion on the allocation of a site for construction;

- permission to put into operation the facility allocated for the premises of the workshop;

- technological maps of production (formulations of finished products indicating the parameters of all operations);

- documentary approval of the manufactured assortment, which will be produced by the designed workshop;

- an approved list of equipment installed at the enterprise, as well as data on employees and their medical examinations;

- contract for the export of technical and household waste;

- contract for the disinfection of the workshop;

- positive conclusion of the fire inspectorate and SES on the possibility of launching the workshop.

Before starting the production of cheeses, first of all, you should take care of the quality of the raw materials used for this. The main raw materials used in this industry are:

- regular and skimmed milk;

- cream;

- food grade pepsin;

- biological and bacterial starter cultures;

- table salt;

- sodium nitrate and potassium.

Cheese production technology may vary depending on the type of initial product. General scheme for making cheese looks like this:

- stage of preparation of raw materials (milk) for subsequent clotting. In the presence of a small amount of feedstock, in order to obtain a greater yield of the finished product, it should contain as much protein as possible. Milk is subjected to cleaning, cooling, pasteurization and separation;

- cheese ripening stage. In specially designed boilers, the formation of cheese grain takes place, for which the milk is brought to a certain temperature, starter cultures, special enzymes and calcium chloride are added. The resulting mixture matures for up to 14 hours, then coagulates;

- formation stage. At this stage, the clot is given the desired density and excess moisture is released. Further, at a low temperature, cheeses are molded with eyes of the required shape;

- pressing stage. After this stage, the cheese has a perfectly smooth and even surface without pores. In the production of soft cheeses, this operation is either completely absent or carried out in less time (maximum a week);

- ambassador. After shaping, the cheese is salted in special containers or pools, which are filled with a saturated salt solution. For hard cheeses, the duration of salting is several days, for soft cheeses - up to several hours;

- drying and ripening. Occurs in chambers with a set temperature, humidity and air velocity with constant turning. At the end, the cheese is covered with a special protective coating.

Selection of suitable premises

When choosing a room for the organization of a cheese production workshop, the following factors should be considered:

- the area of the premises, depending on the production capacity, should be from 20 square meters;

- hot and cold water supply must be present;

- the workshop must be equipped with a heating, ventilation and sewerage system;

- natural lighting must be present, in its absence or shortage, it is compensated by artificial;

- the configuration of the premises should ensure the exclusion of the intersection of raw materials and finished products;

- there should be a convenient entrance for the supply of raw materials and the export of finished products.

Required Equipment

To open a cheese production workshop, you will need the following equipment:

- containers for raw materials and finished products;

- technological tables;

- racks;

- bath for pasteurization;

- paraffiner to cover the finished cheese;

- press;

- forms for cheeses of the required configuration;

- refrigeration units for storing raw materials for production and finished cheese.

Selection of assortment

When selecting the manufactured assortment of finished products, one should be guided by the technical capabilities of the premises and equipment, as well as the demand for a particular finished product.

In general, cheese producers can produce the following products:

- according to the features of production technology (rennet, brine, sour milk and whey);

- according to the production method (hard, soft and melted);

- according to the source of raw materials (cow, goat, sheep, etc.);

- by the presence of an additional processing operation (with spices, with additives of plant and animal origin, with mold, smoked).

Necessary raw materials and search for suppliers

The following requirements are imposed on the quality of raw materials to obtain a product that meets all the necessary indicators:

- milk used for production must be obtained exclusively from healthy cows;

- milk acidity readings must be at least 6.8;

- the fat content of milk cannot exceed 3.5%, while the protein composition is not less than 3% of the total mass;

- milk cannot contain antibiotics;

- the temperature of the raw material during its acceptance should not exceed 12 degrees.

The search for suppliers should be carried out among the farms available near the workshop, and the closer they are located, the lower the cost of its transportation will be.

Staff

To open the workshop, the following workers and specialists will be needed:

- production technologist;

- workshop foreman;

- equipment operators;

- veterinarian;

- support workers;

- cleaners;

- supply and distribution managers;

- cashier accountant.

Advertising and distribution channels

The main buyers of products produced by the cheese-making shop can be:

- the population as the end consumer;

- ordinary shops and supermarkets;

- catering establishments;

- wholesale firms specializing in the sale of cheeses.

To promote the manufactured products on the market, you can perform the following actions:

- opening a company store;

- visiting shops and supermarkets with price lists and product samples;

- holding various promotions to reduce prices, as well as tasting their products at retail outlets;

- "cold" advertising calls to potential buyers;

- creating your own website, which will contain information about the range of cheeses and prices.

Financial costs of production

To start the production of cheese, the following minimum investments will be required.

One-time costs:

- purchase of industrial equipment - from 550 thousand rubles;

- business registration - from 10 thousand rubles;

- repair and preparation of premises for the launch of production - from 100 thousand rubles;

- staff training - from 30 thousand rubles.

The total amount will be from 690 thousand rubles.

The monthly production costs will be:

- rent of premises - from 30 thousand rubles;

- payment for water, electricity - from 20 thousand rubles;

- salary for workers - from 100 thousand rubles;

- purchase of raw materials for production - from 100 thousand rubles;

- other expenses - from 50 thousand rubles.

total amount monthly production costs can range from 300 thousand rubles.

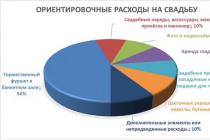

Approximate calculation of profit, profitability payback

The amount of future income, as well as the effectiveness of investing in the opening of a cheese production workshop, can be determined by the following main economic indicators:

- profit from the sale of manufactured products;

- level of profitability;

- payback period of capital investments.

As practice shows, the level of profitability of this business depends on a large number of factors and initial production parameters and is at the level of 10-15% depending on various factors and can bring a monthly profit of 200 thousand rubles or more and pay off in less than a year.

You need to understand that economic indicators, depending on various factors, can change significantly, and only the hard and well-coordinated work of your team will help you get a stable profit.

The history of the organization of a particular cheese business

(No votes yet, be the first to leave)

Oddly enough, but the cheese that we all love to eat can be compared to a person. Just like a person, cheese is born, matures, ages and dies.

By the way, like people, cheeses have their own hierarchy: patriarchs, aristocrats and commoners.

The technology for making hard cheese has hardly changed for centuries.

In small and medium-sized cheese dairies, where traditions are honored, cheese is still made by hand. At large enterprises, cheese production processes are mechanized and automated, and the equipment is equipped with program control.

The initial ingredients from which any hard cheese is made is milk. The technology for making different varieties of hard cheese from milk has much in common, so before you start making cheese, you need to study the general provisions, and then apply various recipes.

1. Milk pasteurization. As you know, there are three modes of pasteurization:

- prolonged, when milk should be heated to 65 ° C and kept for 30 minutes;

- short-term - milk is heated to 75 ° C and kept for 20 minutes;

- instant, when the milk is heated to 90 ° C and not kept.

According to various recipes, hard cheese can be prepared with pasteurized milk, and with fresh, as well as with steam, that is, immediately after milking.

Depending on what kind of milk you use when making cheese, the cheese acquires its own special characteristics and taste.

2. Formation of a clot. After you add a milk-clotting enzyme or starter to milk, a gel forms.

Depending on the temperature at which the starter or enzyme was added to the milk, the result of coagulation (coagulation) of milk will be different.

Depending on the cheese recipe, the resulting coagulate is subjected to various types of processing in order to separate the whey, cut, heated, mixed. This process is called syneresis.

3. Cutting the clot. The coagulum is ready for cutting after a period of 25 minutes to 2 hours, depending on the cheese recipe.

To determine the exact time of cutting the clot, a clean finger test is performed. This is the traditional method used by cheese makers.

The meaning of the test for a clean finger is to dip a finger, probe (spatula) or thermometer into the top layer of the clot and lift it up, as a result of which the clot breaks up, forming a break line.

A clean break with non-spreading edges and green serum at its base indicates that the clot can be cut.

A soft uneven break line with white serum indicates a weak clot strength. On the sides of the break, one can judge the quality of the clot: a granular structure indicates that the clot is too dense.

4. Getting the cheese mass. As a result of the processes performed with cheese, a curd mass is obtained. In fact, this is a ready-made cheese, to which various spices, salt, herbs, nuts, etc. can be added at this stage. The cheese mass is either weighed or pressed.

5. Cheese pressing and self-pressing. At the stage, it is laid out in special forms and subjected to pressing.

You can buy molds for cheese in the online store with delivery.

Pressing can take place in several stages and can be different in terms of pressure.

6. Cheese maturation. At this stage, the cheese should be transferred to a cellar, or some other special room for maturation, where it will need to be carefully looked after.

If you are preparing pickled cheese, then it can both ripen and be further stored in brine.

In the process of ripening, the cheese must be turned over, sometimes washed, brushed. Depending on what kind of cheese is being made, it can even be smoked, wiped with alcohol, sprinkled with spices and perform other manipulations.

It is important that a certain level of humidity and temperature is maintained in the room throughout the entire ripening process, since the final result depends on this.

You can buy a package for cheese maturation in the online store.

Introduction

Cheese is obtained by coagulation of milk with rennet or lactic acid, followed by processing and maturation of the cheese mass. Cheese contains proteins that, when ripe, are broken down into individual amino acids. The digestibility of cheese is 98-99%.

The chemical composition of cheese includes complete proteins (about 25%), which are easily absorbed by the body, milk fat (about 30%), minerals (salts of calcium, sodium, phosphorus, etc.), fat- and water-soluble vitamins (A, D, E, B, B2, PP). Cheeses have a high calorie content and physiological usefulness. Nutritional value, easy digestibility and pleasant taste make it possible to use cheese not only as an excellent food for healthy and sick people, but also as a snack that stimulates the appetite before eating. Cheese is made from cow, goat, sheep and buffalo milk. During the production process, it will retain all the main nutrients of milk, with the exception of carbohydrates. Cheese making removes much of the water from milk, resulting in a concentrated food product.

The industrial production of cheese in Russia began in 1866, when, on the initiative of a prominent public figure, Nikolai Vasilievich Vereshchagin, the first artel cheese factory was opened in the village of Otrokovichi, Tver province.

Advances in technology have allowed producers to better control the cheese-making process, and have also contributed to the standardization of cheeses made with modern production methods. Another result of industrialization was the international distribution of the most famous varieties of cheese. Names that were previously only used for locally produced cheese are now used to describe a method of producing that cheese that can be applied to any locality, and as a result, today there are mozzarellas made in Scotland and Canada, and Cheddar cheeses are made in Ireland and the United States. For many other cheeses, the methods of their production have remained practically unchanged. Such cheeses retain their traditional regional character, thus providing an endless variety of cheeses in the world (Tverdokhleb G.V., Dilanyan Z.Kh. 1991).

Literature review

Cheese production technology

The general technological scheme of cheese production is reduced to the following operations:

1 Acceptance and evaluation of milk quality. In cheesemaking, special requirements are imposed on the quality of raw materials. Milk should be suitable for cheese: it should coagulate quickly, separate whey well, be a good environment for the development of microorganisms, a high content of solids is desirable, which increases the yield of the product and reduces the consumption of raw materials;

2 Cooling milk to 4 °C. It is carried out to prevent the development of microflora and spoilage of milk;

3 Reservation of milk no more than 8 hours. Necessary for the continuous operation of the enterprise;

4 Heating up to 40-45С. It is carried out to reduce the viscosity of milk, as well as to transfer the refractory fraction of fat into a liquid state, which subsequently improves the process of cleaning and separating cream;

5 Purification of milk;

6 Separation of milk. In the process of separation, milk is normalized by fat and cream is separated;

7 Protein normalization, if necessary;

8 Pasteurization at 74 +/-2 °C. Has several goals:

Destruction of vegetative forms of microorganisms.

Inactivation of enzymes in the native state.

9 Preparing milk for curdling;

10 Cooling to clotting temperature 29 - 32 °C;

11 Retaining the mixture.

The prepared product includes:

Specially selected starter cultures

· calcium chloride

· rennet extract

matured milk, if needed.

Particular attention should be paid to sourdough, since the entire ripening process depends on it in the production of cheese. Calcium chloride is needed to increase calcium ions in milk, which in turn bind proteins, which contributes to better clot formation. Sometimes milk of increased maturity is used in production in the amount of 15 - 20% of the total. Such milk also increases the amount of calcium ions, and therefore the quality of the clot. Milk maturation is carried out as follows:

Cooling of pasteurized milk to 8° - 10°C

Introduction of bacterial starter 0.1 - 0.3%

Aging 8 - 10 hours until acidity 20° - 21°T

· Heating up to 30 °C and adding to the total mixture.

Coagulation of milk and obtaining cheese mass:

1 Coagulation of milk 30 - 60 min;

2 Cutting a clot 3 - 10 mm - to start separating whey;

3 Setting grain;

4 Kneading the clot 10 -20 min. It is necessary to accelerate the dehydration of the mass;

5 Removal of 30% serum;

6 Second heating 38 - 56C. It is used to intensify the release of serum;

7 Partial salting in grain (introduction of water);

8 Mixing and removal of another 30% whey;

9 Molding. It is necessary to connect the cheese grain into a single layer. There are 4 ways to mold cheese:

1 from the reservoir,

2 from the clot,

3 in bulk,

4 in bulk.

10 Self-pressing grain. It is carried out for the purpose of dehydration of cheese grain and removal of free moisture;

11 Pressing 2 - 6 -12 hours. Purpose: - obtaining a closed head of cheese - creating a compacted surface of the head - reducing the moisture content of the cheese mass - regulating the microbiological process;

12 Cheese cooling;

13 Ambassador. During salting, certain taste qualities are formed, microbiological and biochemical processes are regulated, and the consistency of the product is also formed. There are 4 ways to salt cheese:

1 salt thick,

2 in brine 10 - 12 °C,

3 in grain,

4 in cheese mass.

14 Drying and packaging of cheese in polyethylene or paraffin (http.smikro.ru).

In the process of maturation of cheese under the action of microorganisms, deep transformations occur with the constituent parts of the cheese. Flavors and aromas accumulate. In the first 7 days, lactose is completely fermented, then proteins break down to polypeptides and amino acids. For most cheeses, the ripening temperature ranges from 16°C to 28°C. The duration of the process is from 2 weeks to 6 months.

The quality of cheeses depends on the raw materials used - milk, which should have a density of at least 1.027 g / cm3, acidity - 16-18 ° T, calcium content - 125 mg, coagulate well under the action of rennet, form a dense clot with good whey separation, be a favorable environment for the development of lactic bacteria. The quality of the cheese depends on the curing process. Table salt gives the cheese a certain taste, regulates microbiological and biochemical processes during its maturation, promotes the formation of a product crust, affects the texture, pattern and yield. The most common method is salting in brine, carried out in brine pools by immersing individual heads in brine. For salting, brine is used with a salt concentration of 13-18% for brine and soft cheeses and 22-24% for hard cheeses. The brine may be whey or aqueous. Whey brine is used for salting pickled cheeses. Cheeses are salted at a temperature of 8-10 ° C for several days.

In modern conditions, the main factors determining the quality of harvested milk are compliance with hygiene requirements, microbiological indicators of milk, feeding and health of cows, acid-base balance of the body and the absence of diseases, as well as the presence of antibiotic residues, other inhibitors that act on lactic acid bacteria are detrimental. Cheese making puts forward certain requirements for milk in many respects. So, in world practice, the upper limit of the content of somatic cells in 1 cm 3 of a milk sample from a quarter of a cow's udder is 5.105 cells, for prefabricated milk it is lower - 3.105 - 5.105 cells. A pronounced change in the chemical composition of milk occurs when the content of somatic cells is 1.106 in 1 cm^3 (A.P. Nechaev 2007).

Milk from vaccinated cows must be supplied separately from bulk milk and processed for technical purposes. The use of such milk for dairy products harms technology, the health of the population and, especially, the health of children. In addition to the above, the duration of rennet coagulation can be extended up to 2-3 hours instead of 20-30 minutes.

The main source of contamination of milk and cheese produced from it with pathogenic staphylococci is cows with mastitis. Impurities of mastitic milk negatively affect the microbiological and biochemical processes of cheese production, resulting in a decrease in the yield and quality of cheese. Therefore, the reduction of mastitis diseases in cows is a condition that contributes to an increase in the production of raw milk.

Currently, the deterioration of the quality of milk is due to the long-term storage of raw milk in the conditions of receiving departments (more than 6 hours at low temperature). Manufacturers should take into account that after storage of raw milk at 40C for 3 days, the proportion of psychrotrophic microorganisms is 10% (in high-quality milk). Due to their lipolytic and proteolytic activity, the cheese suitability of milk decreases, which in fact we have defects in dairy products. An increase in temperature above 100 °C, their number decreases due to competitive microflora, and an increase in temperature above 150 °C is dominated by BGKP; the higher the contamination of chilled milk, the higher the relative number of psychrotrophic microorganisms.

Lipolytic processes caused by psychrotrophic microorganisms in milk lead to the formation of free fatty acids, causing the appearance of a rancid taste in milk and dairy products. Proteases of psychrotrophic bacteria are more heat resistant than lipases. Extracellular proteases, which are formed by the psychrotrophic bacteria Pseudomonas Flavobacterium, withstand ultra-high-temperature treatment of milk at 140 °C. Proteases of the psychrotrophic bacteria Pseudomonas retain partial activity after exposure for 10 min at 120°C. Lipases and proteases of Pseudomonas fluorescens are not inactivated at 90 °C and even withstand this temperature for 20 minutes.

The quality of raw milk should be assessed by the amount of psychrotrophic microflora in it. The risk factor regarding the deterioration of the quality of dairy products is characterized by the value of psychrotrophic bacteria of 104 - 105 CFU / cm3. Cheeses made from raw milk, even at a storage temperature of 40C for 4 days, are characterized by a high content of free fatty acids, which worsens organoleptic characteristics. The main source of psychrotrophic bacteria is soil and water. Their presence in milk can cause spoilage: bitter, fruity and unclean taste, viscous consistency, the prevalence of these bacteria in milk indicates insufficient cleanliness of the equipment or ingress of soil and water.

You can not keep silent about the presence of nitrates and nitrites. They may prevent butyric fermentation, but may harm the health of consumers of milk, cheese, and whey. In the production of cheese with a high temperature of the second heating (Swiss, Ukrainian, Carpathian, Novoselytsky, Carpathian, etc.), which use propionic acid bacteria, the use of nitrates is not recommended because these bacteria die.

It is known that prepared milk already contains nitrates and nitrites on average 1100.10-7 g/cm3 and 2.81.10-7 g/cm3. Their maximum amount falls on June-August. During the production of cheese from such milk, partly nitrates and nitrites (410.10-7 g / cm 3 and 8.2. 10-7 g / cm 3, respectively) pass into whey, which is widely used as a food product and for young animals, which is a certain health hazard. In cheeses, the amount of nitrates reaches 380.10-7 g/kg (http.biysk.ru/zimin/00600/00535.html).

Unfortunately, raw milk in terms of the content of nitrates and nitrites is not controlled in the conditions of enterprises due to the complexity of the analysis methodology. And, of course, the use of direct starter cultures in non-raw milk is unacceptable.

There are two types of cheese production:

1. PRODUCTION TECHNOLOGY OF HARD CHEESES WITH A LOW SECOND HEATING TEMPERATURE

(Hard rennet cheeses are produced from carefully sorted, fat-normalized (taking into account protein content) pasteurized milk with the introduction of various bacterial starter cultures. The production technology, microbiological processes of cheese maturation cause a relatively deep decomposition of proteins, which contributes to obtaining specific properties. chy compositions or polymer films.On the surface of the cheeses are allowed imprints of sickle.The color of the dough is from white to slightly yellow, the same throughout the mass.

The main factors determining the specific features of cheeses of this group are:

The use of bacterial starters, consisting mainly of mesophilic lactic streptococci;

- the temperature of the second heating of the cheese grain - 32-42C (depending on the type of cheese and the ability of the cheese grain to dehydrate);

- a certain level of active acidity of the cheese mass at each stage of production, units. pH: after pressing - 5.2-5.9 in mature cheese - 5.2-5.4;

- moderate content of common salt in cheeses (1.5-2.5%);

- the use of several temperature regimes in the process of maturation (10-12C, 14-16C, 10-12C).

TECHNOLOGICAL PROCESS

2. Cleaning and cooling of milk. It is carried out to prevent the development of microflora and spoilage of milk. To purify milk, it is recommended to use milk purifying filters, and in larger enterprises - milk purifiers. Cooling of milk is carried out to a temperature of 6-8C on plate coolers of appropriate capacity.

3. Reservation and maturation of milk. Reservation of milk lasting 12-24 hours ensures uninterrupted operation of the enterprise. Milk sent to the production of cheese must be ripe (aged at t 10-12C for 10-14 hours in order to increase acidity). Exposure applies to both raw purified and pasteurized milk. Pasteurized milk must be fermented with pure cultures of lactic acid bacteria. It is allowed to use fresh milk with the addition of a share of mature milk (up to 50%).

4. Normalization and pasteurization of milk. Cooling to clotting temperature. Normalization of milk is carried out on separators-cream separators for the fat of the normalized mixture. If necessary, protein normalization is performed (up to ppm protein 3.2%). Pasteurization of milk is carried out on pasteurization-cooling units at t 74-76C with a holding time of 20-25 seconds. The purpose of heat treatment is the destruction of vegetative forms of microorganisms, the inactivation of enzymes that are in their native state, and the preparation of milk for clotting. In the recovery section, the milk is cooled to the clotting temperature (32-34°C).

5. Coagulation of milk, clot processing. In the cheese bath, milk is prepared for rennet coagulation (introduction of bacterial starter; calcium chloride solution; if necessary, ripened milk; rennet). Particular attention should be paid to sourdough, since the entire ripening process depends on it in the production of cheese. A starter consisting of mesophilic streptococci must be active; is introduced in the amount of 0.5-0.8%. It is convenient to use a direct DVS starter, which does not require pre-cultivation of the production starter. Calcium chloride is needed to increase calcium ions in milk, which in turn bind proteins, which contributes to better clot formation. Sometimes in production, milk of increased maturity is used in an amount of 15-20% of the total amount, also in order to increase the amount of calcium ions, and, consequently, the quality of the clot. Rennet ensures the formation of a strong clot in a short time. Coagulation of milk is carried out at t 32-34C for 25-30 minutes.

The resulting clot is subjected to cutting with lira, crushing and kneading for 10-15 minutes in order to set the cheese grain (7-8 mm in size) and dehydrate it. 30% of serum is removed. To accelerate dehydration, the second heating of the cheese grain is carried out under the following modes: t 38-41C, duration 15-30 minutes. To increase the hydrophilicity of the grain, its partial salting is used, which ensures an increase in the content of bound moisture in the cheese. Kneading cheese grain after the second heating for 30-50 minutes is also carried out for its dehydration and grain normalization in terms of moisture. Acidity in the process of processing cheese chamois is regulated by diluting whey with water in an amount of 5-20%. The grain size at the end of processing is 4-5 mm.

6. Molding. For this group of cheeses, plastic molding is traditionally used. The finished cheese grain is pumped into the apparatus for molding the cheese mass for 15-25 minutes to form a layer and cut it into pieces of the required size. 7. Self-pressing. Pieces laid in cheese molds are subjected to self-pressing for 25-30 minutes - pressing under their own weight. At the end of self-pressing, the cheeses are marked with plastic numbers.

8. Pressing. In presses, pressing is carried out for the purpose of final dehydration of the curd and removal of free moisture, obtaining a well-closed surface and a compacted surface layer. Pressing is carried out from 1.5 to 4 hours. 9. Salting. The most rational way of salting hard rennet cheeses is salting in circulating brines with a concentration of 18-22% and a temperature of 8-12C for 3-5 days. For this group of cheeses, partial salting of the cheese mass in the grain is allowed. Salting gives the cheese certain flavors. During salting, microbiological and biochemical processes are regulated, and the consistency of the product is formed.

10. Cheese maturation, care. Before ripening, the cheese is dried for 2-3 days. In the process of ripening, as a result of the vital activity of microorganisms, deep transformations of the constituent parts of the cheese occur, flavoring and aromatic substances accumulate, and the taste of the product is formed. Cheese maturation must take place in maturation chambers under certain conditions (temperature, relative humidity). During the entire ripening time, careful care of the heads is necessary. The total duration of maturation is 1.5-2.5 months.

11. Packing cheese. After maturation, the cheeses are washed, dried, labeled, coated with a paraffin alloy using paraffin wax, or packed in polymer films.

2. PRODUCTION TECHNOLOGY OF HARD CHEESES WITH A HIGH SECOND HEATING TEMPERATURE

(Hard rennet cheeses are produced from carefully sorted, fat-normalized (taking into account protein content) pasteurized milk with the introduction of various bacterial starter cultures. The microbiological processes of cheese maturation determine the relatively deep decomposition of proteins, which contributes to obtaining specific properties. compositions or polymeric films.On the surface of the cheeses, sickle prints are allowed.The color of the dough is from white to slightly yellow, the same throughout the mass.

The main factors determining the specific characteristics of cheeses with a high temperature of the second ripening are:

The use of bacterial starters, consisting of mesophilic (for cheeses of certain types) and thermophilic lactic streptococci and lactic acid bacilli;

- the use of pure cultures of propionic acid bacteria and active propionic acid fermentation during the maturation of cheeses;

- the temperature of the second heating of the cheese grain - 47-58C (depending on the type of cheese and the ability of the grain to dehydrate);

- reduced moisture content of cheese after pressing (38-42%);

- a certain level of active acidity of the cheese mass at each stage of production, units. pH: after pressing - 5.5-5.8, in three-day cheese - 5.3-5.4, mature - 5.5-5.7;

- reduced content of table salt in cheeses (0.8-2.5); - the use of several temperature regimes in the process of ripening cheese (mainly 10-12C and 20-25?C).

TECHNOLOGICAL PROCESS

Increased maturity and acidity of the processed milk and a high level of lactic acid process (Russian), and for Cheddar also ripening (cheddarization) of the cheese mass in blocks before salting and foaming. The production of hard cheeses with a high temperature of the second heating is less than 5% of the total output in Russia. Due to the long ripening time (more than 90 days) of the cheese. The consequence is the slow turnover of the capital of the cheese factory.

1. Acceptance and evaluation of milk quality. In cheesemaking, special requirements are imposed on the quality of raw materials. Raw materials must be of good quality in microbiological terms; a high content of solids, especially protein, is desirable, which increases the yield of the product and reduces the consumption of raw materials Raw milk should quickly coagulate under the action of rennet, form a clot that separates the whey well.

2. Cleaning and cooling of milk. It is carried out to prevent the development of microflora and spoilage of milk. To purify milk, it is recommended to use milk purifying filters, and in larger enterprises - milk purifiers. Cooling of milk is carried out to a temperature of 6-8°C on plate or tubular coolers of appropriate capacity.

3. Reservation and maturation of milk. Reservation of milk lasting 12-24 hours ensures uninterrupted operation of the enterprise. Milk sent to the production of cheese must be ripe (aged at t 10-12C for 10-14 hours in order to increase acidity). Exposure applies to both raw purified and pasteurized milk. Pasteurized milk must be fermented with pure cultures of lactic acid bacteria. It is allowed to use fresh milk with the addition of a share of mature milk (up to 50%). 4. Normalization and pasteurization of milk. Cooling to clotting temperature. Normalization of milk is carried out on separators-cream separators for the fat of the normalized mixture. If necessary, protein normalization is performed (up to 3.2% ppm protein). Pasteurization of milk is carried out on pasteurization-cooling units at t 74-76C for 20-25 seconds. The purpose of heat treatment is the destruction of vegetative forms of microorganisms, the inactivation of enzymes that are in their native state, and the preparation of milk for clotting. In the recovery section, the milk is cooled to the clotting temperature (32-34C).

5. Coagulation of milk, clot processing. The acidity of milk before curdling should be 19-22T. In the cheese bath, milk is prepared for rennet coagulation (introduction of bacterial starter; calcium chloride solution; if necessary, ripened milk; rennet). For Russian cheese, starter is used from strains of lactic acid and aroma-forming streptococci in the amount of 0.7-1.2%. For Cheddar - sourdough from strains of Str. cremoris, Str. lactis, Lbm. plantarum in the amount of 1.5-2.0%. Calcium chloride is needed to increase calcium ions in milk, which in turn bind proteins, which contributes to better clot formation.

Sometimes milk of increased maturity is used in production in the amount of 15 - 20% of the total amount, also in order to increase the amount of calcium ions, and, consequently, the quality of the clot. Rennet ensures the formation of a strong clot in a short time. Milk clotting is carried out at t 32-34C for 30-35 minutes. The resulting clot is cut, set and dried for 35-45 minutes for Russian cheese and 45-50 minutes for Cheddar. Grain size 7-8 mm. 30% of serum is removed. To accelerate dehydration, the second heating of the cheese grain is carried out under the following modes: t 39-41C, duration 20-30 minutes. Drying of cheese grain after the second heating is carried out for 40-50 minutes. The duration of the entire treatment is 120-150 minutes. The grain size at the end of processing is 5-6 mm.

RUSSIAN CHEESE

Partial salting of Russian cheese is carried out at the end of drying the cheese grain before molding (50-70% of the whey is removed before this). Concentrated brine is applied to the grain. Salted grain is kept for 25-30 minutes with stirring.

FORMING

Ready for molding cheese grain is pumped to the whey separator, from where it is fed in bulk into molds. Self-pressing in the forms of cheese mass lasts 50-60 minutes with a single turn. Pressing lasts 3-4 hours, then the cheeses are repressed, then pressed for 2-3 hours until the active acidity of pH 5.2-5.3 increases. (Total pressing time 5-8 hours). The duration of salting cheese in brine is 2-3 days, the temperature of the brine is 10-12C The cheese is dried for 8-10 days, then covered with a paraffin-polymer alloy. The total duration of maturation is 60 days.

CHEDDAR

The processes of cheddarization, molding and pressing of cheese are carried out at a room temperature of 30-35C in order to intensively develop the lactic acid process. A 25-30 cm thick layer formed in the molding apparatus is kept under a whey layer for 30-40 minutes. Then the cheese layer is pressed, cut into blocks (25x24 cm), stacked in several rows on carts, subjected to cheddarization. Blocks are turned 4-6 times every 15 minutes. Cheddarization (ripening of the cheese mass for 90-100 minutes to pH 5.2-5.3) of the cheese mass is carried out in blocks before salting. As a result of ripening, the consistency of the cheese mass becomes layered-fibrous.

CRUSHING, SALTING

In the crushing device, the cheese mass bars are crushed into pieces of 1.5-2 cm, evenly salted.

FORMING

The cheese is molded into rectangular blocks and placed in perforated moulds. Self-pressing is carried out for 20-30 minutes. Pressing lead 8-14 hours. Drying 2-3 hours. The cheese is packed in polymer films under vacuum with heat shrink. Ripening 90 days.

Information provided by NPK "Progressive Technologies". The company supplies a wide range of equipment for the production of processed and sausage cheeses. We offer both fully equipped production and packaging lines, as well as disparate equipment, ranging from cheese mass melters to automatic packaging machines in a variety of consumer containers. The company's technologists will tell you in more detail about the production technology and correctly select the required equipment.

Phones in Moscow:

Secretariat: 933-60-63; fax: 933-60-64.

Company website: WWW.PROTEX.RU, E-mail: [email protected].